Cold Rolled Stainless Steel, Stainless Plates Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

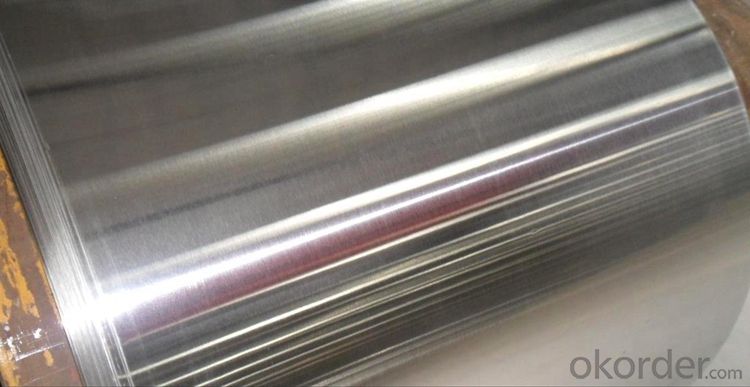

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform under tension before breaking. It is typically expressed as a percentage and represents the maximum strain the steel can undergo without fracturing.

- Q: How do you attach stainless steel sheets to a wall?

- There are various methods available for attaching stainless steel sheets to a wall. Consider the following options: 1. Utilize adhesive: Apply a specialized construction adhesive for metal bonding onto the rear surface of the stainless steel sheet. Press the sheet firmly against the wall and maintain pressure until the adhesive cures. This technique suits smaller and lighter stainless steel sheets. 2. Implement screw fasteners: Drill holes through both the stainless steel sheet and the wall at regular intervals. Use stainless steel screws suitable for the sheet thickness and wall material. Insert the screws into the holes and tighten them until the sheet is securely affixed to the wall. This method is effective for larger and heavier stainless steel sheets. 3. Opt for magnetic mounting: If the stainless steel sheet possesses magnetic properties, you can employ magnets to attach it to a metal wall. Place strong magnets on the back of the sheet, aligning them with magnets on the wall. The magnets will hold the sheet in position, allowing for easy installation and removal. 4. Consider panel mounting systems: Some manufacturers offer specialized panel mounting systems specifically designed for stainless steel sheets. These systems typically consist of brackets or clips that attach to the back of the sheet and then hook onto a track or rail system mounted on the wall. This method ensures a secure and visually pleasing attachment solution. When attaching stainless steel sheets to a wall, it is crucial to ensure that the wall surface is clean, dry, and properly prepared. This will optimize adhesion and prevent potential issues. Additionally, always adhere to the manufacturer's instructions and guidelines for the specific method or product being employed.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: Can stainless steel sheets be used for fire-rated applications?

- Yes, stainless steel sheets can be used for fire-rated applications. Stainless steel has excellent fire resistance properties, including high melting points and low thermal expansion. It does not emit toxic fumes when exposed to high temperatures, making it a suitable material for fire-rated applications such as fire doors, wall panels, and fire-rated enclosures.

- Q: Stainless steel plate more than the thickness of the wire can not be drawn ah?

- Cold can be the basic drawing, cold always have 6, but can also be hot drawing due to the surface, the surface of the hot rolling drawing look is not obvious, many processing plants also willing to help you fill wire drawing, hot rolled board should be relatively large, artificial lift, so drawing up a lot of trouble....12 thick thought it should be no problem

- Q: How do you prevent galvanic corrosion on stainless steel sheets?

- One way to prevent galvanic corrosion on stainless steel sheets is to ensure that they are not in direct contact with dissimilar metals. This can be achieved by using insulating materials, such as rubber gaskets or plastic washers, between the stainless steel sheets and any other metal surfaces they come into contact with. Additionally, regular cleaning and maintenance of the stainless steel sheets can help remove any potential corrosive agents and minimize the risk of galvanic corrosion.

- Q: Stainless steel plate how to distinguish between good and bad, there are several thick?

- The entire stainless steel material, its origin is generally mills order or to import and processing of goods due to overstocking of society. The sources of stainless steel are different, and the methods of identification are different.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat metal plates made from an alloy of iron, chromium, and other elements that prevent corrosion and rusting. They are commonly used in various industries such as construction, automotive, and manufacturing, due to their durability, strength, and resistance to staining and oxidation.

- Q: Who knows the production process of stainless steel plate?

- The process of stainless steel: if annealed stainless steel should be used to have NG-9-1 chemical black oil by NZ-B in electrolytic oil washing, polishing, degreasing Wang (the fluid as the coolant used directly, temperature 60 to 80 DEG C, the workpiece hanging the anode current of Da:20 ~ 15A/dm2, the cathode lead - antimony alloy (with sb 8%) time: 1 ~ 10 minutes), washing, polishing until 5 ~ 8% hydrochloric acid stripping (room temperature: 1 ~ 3 seconds), water washing and drying.Note: aluminum or titanium for fixture requires good electrical conductivity. The new solution is electrically treated before aging.

- Q: Are stainless steel sheets easy to install?

- Yes, stainless steel sheets are relatively easy to install. They usually come in standard sizes and can be easily cut to fit specific dimensions if needed. Stainless steel sheets are lightweight and can be easily handled, making the installation process more convenient. Additionally, they often come with pre-drilled holes, which allows for easy attachment to various surfaces. With proper tools and basic knowledge of installation techniques, stainless steel sheets can be installed in a straightforward manner.

Send your message to us

Cold Rolled Stainless Steel, Stainless Plates Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords