Steel Rebar Hs Code Import Duty and Taxes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Rebar Hs Code Import Duty and Taxes

Description of Steel Rebar HS Code:

1, Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40 rods reinforcing Steel Rebar HS Code

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Steel Rebar HS Code:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

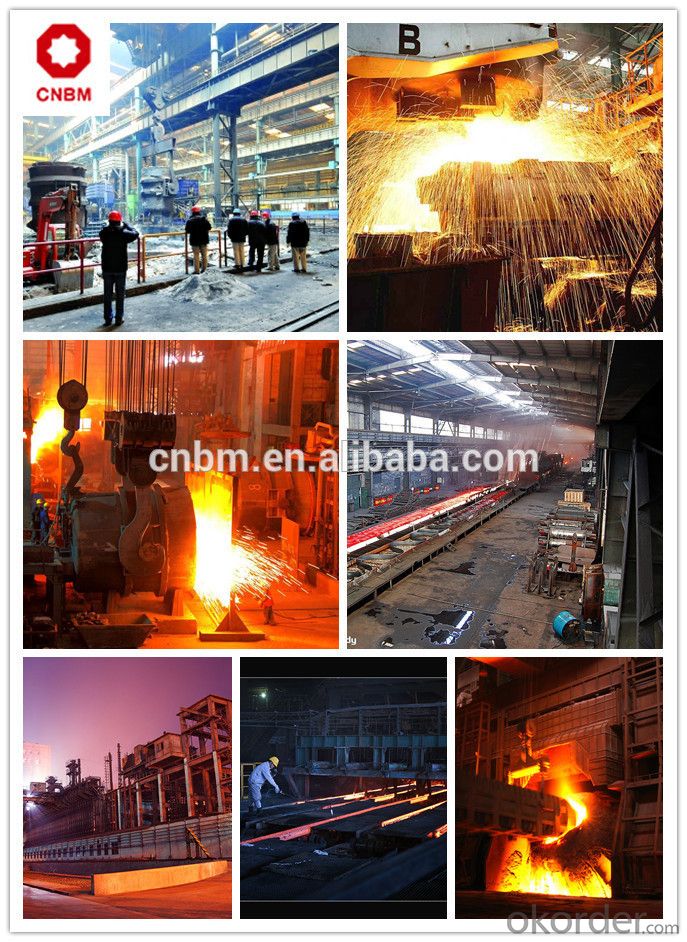

Product Show of Steel Rebar HS Code:

Workshop

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Contact Us:

- Q: How does special steel contribute to improving product safety in high-risk industries?

- Special steel plays a crucial role in improving product safety in high-risk industries due to its unique properties and characteristics. Its exceptional strength, durability, and resistance to corrosion make it highly reliable and less prone to failure under extreme conditions. By using special steel in the manufacturing of critical components and structures, such as in aerospace, automotive, and oil and gas industries, it ensures enhanced safety and prevents potential accidents or catastrophic failures. Additionally, the strict quality control and certifications associated with special steel guarantee that it meets the industry's stringent safety standards, providing peace of mind to both manufacturers and end-users.

- Q: What are the different techniques used for joining special steel?

- There are several techniques used for joining special steel, including welding, brazing, soldering, and adhesive bonding. Welding is the most common method, which involves melting the base material and adding a filler material to create a strong bond. Brazing uses a filler metal with a lower melting point than the base material, while soldering uses a lower melting point filler metal. Adhesive bonding involves using a special adhesive to bond the steel parts together. Each technique has its advantages and limitations, and the choice depends on the specific requirements of the application.

- Q: How does special steel contribute to the agricultural sector?

- Special steel contributes to the agricultural sector in several ways. Firstly, special steel is known for its strength and durability, making it an ideal material for manufacturing various agricultural machinery and equipment. This includes tractors, plows, harvesters, and irrigation systems, among others. These machines require robust and reliable components that can withstand the demanding conditions of agricultural work, and special steel provides the necessary strength and resistance to wear and tear. Additionally, special steel can be used to produce high-quality cutting tools that are essential in farming operations. Implements such as sickles, scythes, and pruning shears need to have sharp and durable blades to efficiently cut through vegetation. Special steel's hardness and strength make it a suitable material for manufacturing these tools, ensuring they retain their sharpness even after prolonged use. Furthermore, special steel can contribute to the agricultural sector by enabling the construction of sturdy and durable infrastructure. Agricultural buildings, storage facilities, and fencing often require strong and corrosion-resistant materials to withstand the elements and protect crops, livestock, and equipment. Special steel, with its resistance to rust and structural integrity, can be used in the construction of barns, silos, sheds, and fencing, providing long-lasting and reliable structures. In conclusion, special steel plays a crucial role in the agricultural sector by providing the necessary strength, durability, and corrosion resistance required for the manufacturing of machinery, cutting tools, and infrastructure. Its properties contribute to improved efficiency, productivity, and reliability in agricultural operations, ultimately benefiting farmers and the overall agricultural industry.

- Q: What are the different heat treatment processes for special steel?

- There are several different heat treatment processes for special steel, including annealing, quenching, tempering, case hardening, and precipitation hardening.

- Q: What are the main advantages of using special steel in the defense industry?

- The main advantages of using special steel in the defense industry are its exceptional strength, durability, and resistance to wear and tear. Special steel alloys can withstand extreme conditions, such as high temperatures and pressures, making them ideal for military applications. Additionally, special steel offers enhanced corrosion resistance, ensuring the longevity of defense equipment even in harsh environments. Its high impact resistance and ability to absorb shock also make it valuable in protecting soldiers and military vehicles. Overall, special steel provides crucial advantages in terms of reliability, performance, and protection for the defense industry.

- Q: What are the advantages of using special steel in aerospace applications?

- There are several advantages of using special steel in aerospace applications. Firstly, special steel offers exceptional strength and durability, making it suitable for withstanding the extreme conditions and stresses experienced during flight. This ensures the structural integrity and safety of the aircraft. Secondly, special steel has excellent corrosion resistance properties, which is crucial for protecting the aircraft components from the harsh environment and moisture encountered in the aerospace industry. Additionally, special steel can be tailored to meet specific requirements such as high-temperature resistance or low weight, allowing for efficient design and optimization of aerospace components. Lastly, special steel is readily available and cost-effective, making it a practical choice for aerospace manufacturers. Overall, the use of special steel in aerospace applications enhances the performance, reliability, and longevity of aircraft components.

- Q: What are the different methods of surface passivation for special steel?

- Surface passivation methods for special steel vary in order to enhance its corrosion resistance and overall performance. One popular approach is chemical passivation, where a protective coating is applied to the steel's surface. This coating, composed of substances like chromium oxide or nitric acid, is typically formed through a chemical reaction that creates a protective layer. Chemical passivation is commonly used in industries where the steel is exposed to corrosive environments, such as marine or chemical applications. Another method is mechanical passivation, which involves physically altering the steel's surface to create a protective barrier. This can be achieved through techniques like shot peening or sandblasting, which create a roughened surface that is less prone to corrosion. Mechanical passivation is often employed in situations where the steel is exposed to abrasive or erosive conditions, such as mining or oil drilling. Electrochemical passivation is yet another technique used to passivate special steel surfaces. It entails using an electric current to generate a protective oxide layer on the steel's surface. Processes like electrochemical polishing or anodizing achieve this controlled oxidation. Electrochemical passivation is frequently utilized in industries where the steel is subjected to high temperatures or aggressive chemical environments. Additionally, specialized surface treatments, like plasma or laser surface passivation, are available for special steel. These methods utilize concentrated energy sources to modify the steel's surface and create a protective layer that enhances its corrosion resistance and mechanical properties. Such treatments are typically applied in high-performance applications, such as the aerospace or automotive industries. Ultimately, the choice of surface passivation method for special steel depends on the specific requirements of the application and the desired performance characteristics of the material. Each method has its own advantages and limitations, and factors like cost, time, and environmental impact should be considered when selecting the most suitable method for a particular application.

- Q: What are the properties of magnetic steel?

- Magnetic steel is characterized by its ability to attract and hold a magnetic field. It has a high magnetic permeability, allowing it to easily magnetize and demagnetize. Magnetic steel also exhibits high coercivity, meaning it has a strong resistance to losing its magnetization. Additionally, it possesses high electrical conductivity and is often used in various applications such as transformers, motors, and magnetic storage devices.

- Q: How does special steel perform in high-vibration applications?

- Special steel is known for its excellent performance in high-vibration applications. Its unique composition and properties make it highly resistant to the effects of vibration, ensuring optimal performance and durability in such environments. One of the key features of special steel is its high tensile strength. This strength allows it to withstand the forces and stresses generated by vibration without undergoing deformation or failure. This property is vital in high-vibration applications, where constant movement and oscillation can subject materials to significant stress. Moreover, special steel exhibits exceptional fatigue strength, meaning it can endure repeated cycles of stress and vibration without compromising its structural integrity. This makes it ideal for applications that involve continuous or cyclic vibration, such as machinery, equipment, and structures subjected to dynamic loads. Additionally, special steel possesses excellent damping properties. Damping refers to the ability of a material to absorb and dissipate energy generated by vibrations. Special steel's superior damping characteristics help reduce the magnitude and duration of vibrations, minimizing the impact on the surrounding components and structures. This contributes to overall system stability and reduces the risk of fatigue or premature failure. Furthermore, special steel is often engineered to have high resistance to corrosion and wear. This resistance ensures that the material remains robust and reliable even in harsh environments where vibration-induced corrosion or erosion may occur. By maintaining its protective coating and integrity, special steel can effectively withstand the challenges posed by high-vibration applications. In summary, special steel performs exceptionally well in high-vibration applications due to its high tensile strength, fatigue resistance, damping properties, and corrosion/wear resistance. Its combination of these properties ensures optimal performance, longevity, and safety in environments characterized by significant vibration and dynamic loads.

- Q: What are the requirements for special steel used in power generation equipment manufacturing?

- The standards for manufacturing special steel used in power generation equipment are very strict. The steel must be incredibly strong and durable in order to withstand the extreme conditions and heavy loads that power generation equipment experiences. This includes the ability to handle high temperatures, pressure, and mechanical stress. In addition to these requirements, the steel used in power generation equipment must also have excellent resistance to corrosion and oxidation. Since power generation equipment often operates in challenging environments, such as high humidity or exposure to corrosive substances, the steel must be highly resistant to ensure it lasts a long time and performs well. Furthermore, the steel used in power generation equipment must be easy to weld and shape. This is important for the manufacturing process, as power generation equipment often requires complex shapes and structures. The ability to accurately weld and shape the steel is essential. Another important requirement is the steel's ability to maintain its mechanical properties at high temperatures. Power generation equipment, like boilers or turbines, operates at elevated temperatures, and the steel used must retain its strength, resistance to deformation, and dimensional stability under these conditions. Finally, the special steel used in power generation equipment must meet industry standards and specifications. These standards ensure that the steel used in manufacturing is of high quality, reliable, and safe. Compliance with these standards is crucial to ensure the equipment performs well and lasts a long time. Overall, the requirements for special steel used in power generation equipment manufacturing are demanding. The steel must be strong, durable, resistant to corrosion and oxidation, easy to weld and shape, able to withstand high temperatures, and compliant with industry standards. Meeting these requirements is vital for the efficient and reliable operation of power generation equipment.

Send your message to us

Steel Rebar Hs Code Import Duty and Taxes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords