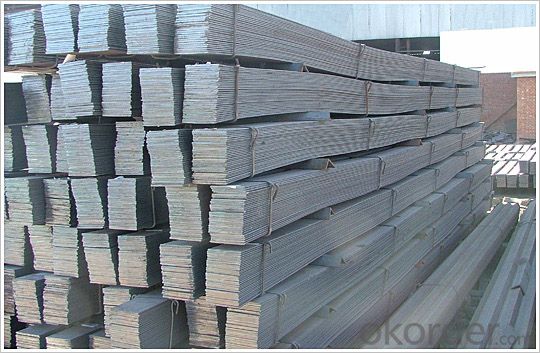

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

| Name | carbon hot rolled black mild steel flat bar |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 1.5mm-14mm |

| Length | 6-12m |

| Technique | carbon hot rolled black mild steel flat bar |

| Tolerance | As the standard or as your requirement |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | BV carbon hot rolled black mild steel flat bar |

| MOQ | 25 tons |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How strong are steel flat bars?

- Strength and durability are characteristics commonly associated with steel flat bars. The grade and composition of the steel used can affect the strength of these flat bars. Mild steel, which contains a low amount of carbon, is often used to create steel flat bars due to its ductility and ease of manipulation. Mild steel flat bars possess moderate strength and find application in various fields, including construction, manufacturing, and fabrication. Conversely, high-strength steel flat bars, crafted from alloys or subjected to heat treatment, exhibit significantly enhanced strength properties. These specialized flat bars are designed to endure substantial loads, resist deformation, and offer structural support in demanding scenarios. Their usage is prevalent in industries such as construction, automotive, and aerospace. In general, steel flat bars are acknowledged for their strength and capacity to withstand substantial force and weight. Nonetheless, selecting the appropriate grade and size of steel flat bar for a particular application is crucial to ensure optimal strength and performance. Consulting with a structural engineer or steel supplier can aid in determining the most suitable type of steel flat bar for a specific project.

- Q: How do steel flat bars compare to other types of steel profiles?

- Steel flat bars have several advantages compared to other types of steel profiles. Firstly, they have a flat surface that makes them ideal for applications where a smooth and even support is required. This characteristic also allows for easy welding, cutting, and shaping, making them versatile for various construction and manufacturing projects. Additionally, steel flat bars offer excellent strength and durability, making them suitable for structural purposes. They are also cost-effective and readily available, making them a popular choice in the industry. Overall, steel flat bars provide a great balance of strength, versatility, and affordability, making them a preferred option among other types of steel profiles.

- Q: How do you remove burrs or sharp edges from steel flat bars?

- There are several methods available for removing burrs or sharp edges from steel flat bars: 1. Grinding: Utilizing a grinding wheel or belt sander is a commonly used technique. Simply hold the steel flat bar firmly and glide it along the grinding wheel or belt sander, applying moderate pressure. Move the bar back and forth, ensuring all edges are evenly ground until the burrs or sharp edges are eliminated. 2. Deburring tools: Various handheld deburring tools specially designed for eliminating burrs and sharp edges from metal surfaces can be found on the market. These tools typically have a handle with a replaceable blade or cutting bit. Securely hold the steel flat bar and run the deburring tool along the edges to shave off the burrs. 3. File: Another effective tool for removing burrs from steel flat bars is a metal file. Choose a file with a fine or medium tooth pattern, depending on the severity of the burrs. Hold the file at an angle to the steel bar and apply even pressure while moving it back and forth along the edges. Continue filing until the burrs are smoothed out. 4. Sandpaper: If the burrs are not too severe, sandpaper can also be used. Begin with a coarse-grit sandpaper and gradually progress to finer grits until the burrs are no longer present. Wrap the sandpaper around a wooden block or use your hand to sand the edges evenly. Always remember to wear protective gloves and eyewear when working with metal to avoid injury. Additionally, it is crucial to securely fasten the steel flat bar before attempting any of the aforementioned methods to ensure stability and prevent accidents.

- Q: Are steel flat bars available in different grades?

- Different grades of steel flat bars are available. These grades are determined by the chemical composition, mechanical properties, and intended use of the bars. Mild steel, carbon steel, stainless steel, and alloy steel are common examples of these grades. Each grade possesses distinct properties and characteristics that make them suitable for specific applications. When choosing the appropriate grade, factors like required strength, corrosion resistance, machinability, and weldability must be taken into consideration. The specific requirements of the project or application should be carefully considered in order to select the most suitable grade of steel flat bar.

- Q: Can steel flat bars be used for manufacturing agricultural equipment or machinery?

- Certainly! Agricultural equipment and machinery can indeed be manufactured using steel flat bars. Steel, being a robust and long-lasting material, possesses the ability to endure the demanding loads and challenging environments frequently encountered in agricultural contexts. By shaping, welding, and molding steel flat bars, one can create the necessary components for agricultural equipment, including plows, cultivators, trailers, and machinery parts. The adaptability and versatility of steel make it an ideal and dependable option for the production of agricultural machinery and equipment.

- Q: Can steel flat bars be used for tool and die making?

- Yes, steel flat bars can be used for tool and die making. Tool and die making requires materials that are strong, durable, and can withstand the high pressures and temperatures involved in the manufacturing process. Steel flat bars are often chosen for this purpose due to their excellent strength-to-weight ratio and resistance to wear and tear. They can be easily machined, shaped, and hardened to meet the specific requirements of the tool or die being fabricated. Additionally, steel flat bars are readily available in various sizes and grades, making them a versatile choice for tool and die making applications.

- Q: How is a steel flat bar made?

- A steel flat bar is typically made through a process called hot rolling. The process begins with heating a large steel billet or slab to a high temperature, typically around 1200 to 1300 degrees Celsius. The heated billet is then passed through a series of rolling mills, where it is gradually flattened and shaped into a long, thin strip known as a flat bar. In each rolling mill, the steel billet is passed through a pair of rotating rolls, which exert pressure on the billet and gradually reduce its thickness. The billet is rolled multiple times, with the gap between the rolls getting smaller with each pass. This continuous rolling process helps to refine the grain structure of the steel, improving its strength and durability. After the desired thickness is achieved, the flat bar may undergo additional processes such as cooling, straightening, and cutting to the required length. Cooling is typically done using air or water to rapidly cool the steel and lock in its desired properties. Straightening helps to remove any bends or twists that may have occurred during the rolling process, ensuring a uniform flat shape. Once the flat bar is cooled and straightened, it is cut into individual lengths using shearing or sawing machines. These lengths can then be further processed or used as is for various applications. Overall, the production of a steel flat bar involves heating a steel billet, hot rolling it through a series of rolling mills to achieve the desired thickness, cooling, straightening, and finally cutting it into individual lengths. This process results in a versatile and widely used product that finds applications in industries such as construction, manufacturing, and automotive.

- Q: Are steel flat bars suitable for machine frames?

- Indeed, machine frames can generally be constructed using steel flat bars. Steel is renowned for its robustness, longevity, and ability to withstand wear and tear, which renders it a prevalent selection for machine frames across diverse industries. The flat and rectangular shape of steel flat bars proves especially advantageous for the construction of machine frames as it facilitates effortless welding and assembly. Moreover, steel flat bars provide exceptional stability and rigidity, ensuring that the machine frame can effectively bear the weight and vibrations produced during machine operation. In summary, steel flat bars furnish a dependable and solid base for machine frames, making them a fitting choice for this purpose.

- Q: Can steel flat bars be used for making tools or machinery?

- Yes, steel flat bars can be used for making tools or machinery. Steel is a widely used material in tool and machinery manufacturing due to its high strength, durability, and versatility. Steel flat bars can be easily shaped, cut, or welded to create various tools and machine parts, making them a suitable choice for such applications.

- Q: Can steel flat bars be used for manufacturing tools?

- Yes, steel flat bars can be used for manufacturing tools. Steel flat bars are commonly used in tool manufacturing due to their high strength, durability, and versatility. These bars can be easily shaped and machined into various tool designs, making them suitable for a wide range of applications. Steel flat bars are also known for their resistance to wear and tear, making them ideal for tools that require frequent use and contact with hard materials. Additionally, steel flat bars can be heat-treated to enhance their mechanical properties, such as hardness and toughness, further improving their suitability for tool manufacturing.

Send your message to us

Steel Flat Bar Q235 Hot Rolled Black Mild Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords