Steel Coils Steel Plates Steel Sheets SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

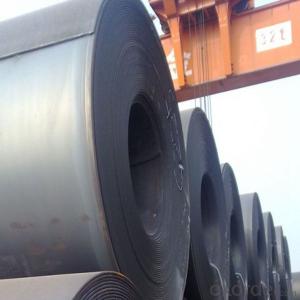

DETAILED PICTURES FOR STEEL COILS

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

FAQ

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What is the difference between a smooth and perforated stainless steel sheet?

- A smooth stainless steel sheet is one that possesses a uniform and flat surface, devoid of any visible texture or patterns. It finds its typical usage in scenarios where a sleek and polished appearance is sought after, like in architectural designs or decorative elements. In contrast, a perforated stainless steel sheet is characterized by the presence of small or large holes that have been punched or drilled into it, resulting in an arrangement of openings on its surface. These openings can take various shapes, such as round, square, or any other, depending on the desired aesthetic or functional requirements. Perforated sheets are commonly employed in situations where ventilation, filtration, or visibility is necessary, such as in industrial equipment, acoustic panels, or safety grating. The primary distinction between a smooth and perforated stainless steel sheet lies in the presence or absence of holes on the surface. While a smooth sheet offers a pristine and uninterrupted appearance, a perforated sheet offers several advantages, including improved airflow, enhanced visibility, and increased sound absorption. Furthermore, the choice between a smooth or perforated sheet hinges on the specific application and the desired functionality. Smooth sheets are ideal for situations that call for a seamless and polished look, while perforated sheets are well-suited for applications that necessitate functionality, such as filtering, screening, or facilitating airflow.

- Q: Are steel sheets suitable for high-temperature applications?

- Yes, steel sheets are suitable for high-temperature applications due to their high melting point, excellent strength, and heat resistance properties. Steel sheets can withstand extreme temperatures without losing their structural integrity, making them ideal for applications such as furnace linings, heat exchangers, and exhaust systems.

- Q: Can steel sheets be used for roofing?

- Yes, steel sheets can be used for roofing. Steel is a durable and strong material that offers excellent protection against weather elements and is often used as a roofing material in residential and commercial buildings.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel sheets are versatile, durable, and offer structural integrity, making them suitable for various architectural uses such as roofing, cladding, and facades. Additionally, steel sheets can be easily shaped, allowing for creative and unique designs in architectural projects.

- Q: Are the steel sheets easy to transport and handle?

- Yes, steel sheets are relatively easy to transport and handle. They are typically compact and lightweight, making them convenient to move around. Additionally, their flat and rigid nature allows for easy stacking and loading onto transportation vehicles. However, larger and heavier steel sheets may require specialized equipment and machinery for safe handling and transportation.

- Q: What is the maximum thickness available for steel sheets?

- The maximum thickness available for steel sheets depends on various factors such as the type of steel, manufacturing capabilities, and industry standards. However, in general, steel sheets can range from a few millimeters to several inches in thickness.

- Q: What is the typical corrosion resistance of a steel sheet?

- The typical corrosion resistance of a steel sheet can vary depending on factors such as the specific type of steel, the presence of protective coatings, and the environment in which it is exposed. However, steel sheets are generally known for their moderate to high corrosion resistance due to the presence of alloying elements such as chromium and nickel.

- Q: Can steel sheets be bent or folded?

- Yes, steel sheets can be bent or folded. Steel is a highly versatile material that can be manipulated into various shapes and forms. In fact, the ability to bend or fold steel sheets is one of the reasons why it is widely used in construction, manufacturing, and other industries. Bending or folding steel sheets can be achieved through different methods such as press braking, roll bending, or using specialized tools like bending machines. The process involves applying force or pressure to the steel sheet, causing it to deform and take on the desired shape.

- Q: Can steel sheets be used for manufacturing agricultural equipment?

- Yes, steel sheets can be used for manufacturing agricultural equipment. Steel is a commonly used material in the agricultural industry due to its strength, durability, and resistance to corrosion. It can be shaped into various forms, such as sheets, to create components and structures for agricultural machinery and equipment.

- Q: Can steel sheets be used for staircase railings?

- Yes, steel sheets can be used for staircase railings. Steel is a durable and strong material that is commonly used in construction and engineering applications. Steel sheets can be fabricated into various shapes and designs to create stylish and modern staircase railings. They can be easily customized to suit different architectural styles and preferences. Additionally, steel railings are known for their longevity and low maintenance requirements, making them a popular choice for staircase installations.

Send your message to us

Steel Coils Steel Plates Steel Sheets SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords