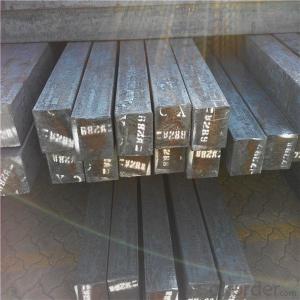

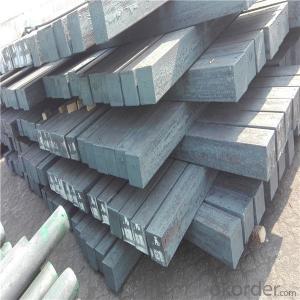

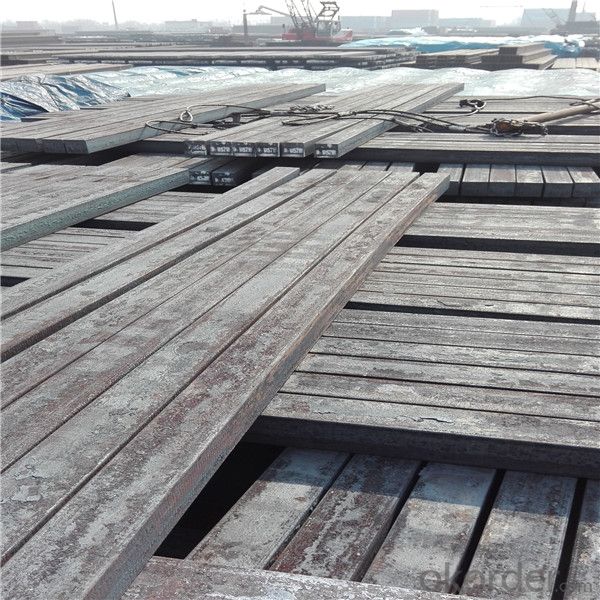

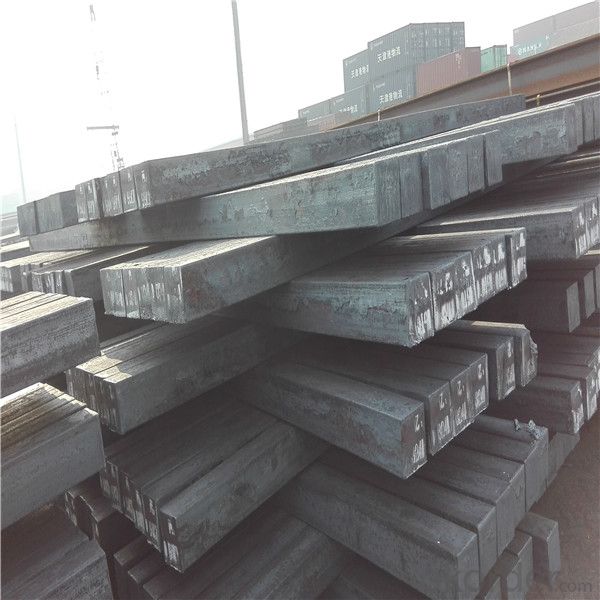

Steel billets Q215 grade hot sale factory price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets

are also known for their malleability and ductility, especially when exposed to varying temperatures during

shaping and molding.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Size :100mm to 165mm

Length:6~12meters

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Can steel billets be used in the production of construction machinery?

- Yes, steel billets can be used in the production of construction machinery. Steel billets are semi-finished steel products that can be further processed into various shapes and sizes, including the components used in construction machinery. These billets can be hot-rolled or cold-rolled to form different types of steel products, such as bars, rods, plates, or sheets, which are commonly used in the construction industry. The high strength and durability of steel make it an ideal material for construction machinery as it can withstand heavy loads, resist corrosion, and provide structural integrity. Therefore, steel billets serve as a crucial raw material in the manufacturing process of construction machinery.

- Q: Can steel billets be used for making musical instruments?

- Musical instruments can indeed be crafted from steel billets. Although conventional instruments are typically fashioned from wood or brass, steel offers a distinctive and contemporary alternative. The strength and durability of steel render it well-suited for certain instruments, including steel drums and steel guitars. Moreover, steel's adaptability permits the formation of intricate designs and shapes, resulting in a broad spectrum of sounds. Nevertheless, it is crucial to acknowledge that the specific attributes and properties of the steel utilized, such as its composition and thickness, will heavily influence the instrument's sound and quality. Therefore, meticulous consideration and experimentation may prove necessary in order to achieve the desired musical tones and effects when employing steel billets for instrument production.

- Q: How do steel billets contribute to the construction of bridges and infrastructure?

- The strength, versatility, and durability of steel billets make them crucial in the construction of bridges and infrastructure. These cylindrical bars of steel are created through a process known as casting, where molten steel is poured into molds and allowed to cool and solidify. A primary benefit of steel billets in bridge construction is their ability to bear heavy loads. Bridges face substantial weights from vehicles, pedestrians, and natural forces like wind and earthquakes. Steel billets, with their remarkable strength and structural integrity, provide the necessary support to withstand these loads and ensure the bridge's safety and stability. Additionally, steel billets offer flexibility in design and construction. Their malleability allows for easy shaping and forming into various structural components, such as beams, columns, and girders, which are vital in bridge construction. This flexibility empowers engineers to create innovative designs and optimize material usage, resulting in cost-effective and efficient bridge structures. Another significant advantage of steel billets is their resistance to corrosion. Bridges endure harsh environmental conditions, including moisture, saltwater, and pollution. Steel billets can be treated with protective coatings or alloyed with elements like chromium or nickel to enhance their corrosion resistance. This guarantees the bridge's longevity and durability, reducing maintenance costs and extending its lifespan. Moreover, steel billets contribute to the speed of bridge construction. As they are prefabricated in steel mills, they can be produced in large quantities and transported to the construction site, ready for assembly. This prefabrication process minimizes on-site construction time, reducing traffic disruption and shortening the overall project duration. In conclusion, steel billets are essential in the construction of bridges and infrastructure due to their high load-bearing capacity, flexibility in design and construction, resistance to corrosion, and ability to expedite construction. Their contribution ensures the safety, longevity, and efficiency of bridge structures, making them a vital component in the development of robust and reliable infrastructure systems.

- Q: What are the main factors affecting the dimensional tolerances of steel billets?

- The dimensional tolerances of steel billets can be influenced by various factors. One of the main factors is the manufacturing process itself. The method used to produce the billets, such as casting or hot rolling, can impact the final dimensions. For example, casting processes may introduce variations in the cooling rate, which can affect the overall shape and size of the billets. Another important factor is the initial quality of the raw material. The composition and homogeneity of the steel used to produce the billets can contribute to dimensional variations. Impurities or uneven distribution of alloying elements can lead to inconsistencies in the size and shape of the billets. The temperature during the manufacturing process is also a significant factor. High temperatures can cause thermal expansion, leading to dimensional changes in the billets. Cooling rates and control of the cooling process are critical to maintaining the desired tolerances. The design and condition of the equipment used in the manufacturing process can also impact the dimensional tolerances. Proper maintenance and calibration of machinery are essential to ensure consistent and accurate production. Finally, external factors such as handling and transportation can affect the dimensional tolerances of steel billets. Improper handling or rough transportation conditions can cause physical deformations or damage to the billets, leading to variations in their dimensions. Overall, the dimensional tolerances of steel billets are influenced by factors such as the manufacturing process, raw material quality, temperature control, equipment condition, and handling and transportation practices. Attention to these factors is crucial to achieving the desired dimensional accuracy in steel billets.

- Q: Use medium frequency furnace (1 million 500 thousand volt ampere) to produce 1 ton cast steel blank, how much kilowatt hour is consumed?

- This depends on the intermediate frequency furnace voltage level and inverter efficiency, the general high voltage will save power, generally 550-700 range, details can refer to wcdlsb site medium frequency furnace data

- Q: What are the different types of steel billet shearing techniques?

- There are several types of steel billet shearing techniques, including guillotine shearing, rotary shearing, and flying shear.

- Q: How do steel billets contribute to the corrosion resistance of a product?

- The corrosion resistance of a product is not directly affected by steel billets. Instead, it is determined by the specific composition and treatment of the steel billets. Steel billets are essentially semi-finished steel products that act as raw materials for various downstream processes like forging, rolling, and extrusion, which ultimately produce the final product. To improve the corrosion resistance of a product, specific alloying elements and controlled processing techniques can be used during the manufacturing of steel billets. For example, stainless steel billets have a higher chromium content, which creates a protective oxide layer called chromium oxide on the steel's surface. This oxide layer acts as a barrier, preventing direct contact between the steel and corrosive environments, thus enhancing the corrosion resistance of the final product. Additionally, steel billets can undergo further treatments like heat treatment, surface coatings, or galvanization to enhance their corrosion resistance. Heat treatment processes like annealing, quenching, or tempering can modify the microstructure of steel billets, resulting in improved corrosion resistance properties. Surface coatings like paint, powder coating, or electroplating can provide an additional layer of protection, preventing direct exposure to corrosive substances. Galvanization involves coating steel billets with a layer of zinc, which acts as a sacrificial anode, corroding instead of the underlying steel to protect it. In conclusion, while steel billets themselves do not directly contribute to the corrosion resistance of a product, the composition, alloying elements, and treatments applied during their manufacturing process play a crucial role in enhancing the corrosion resistance of the final product.

- Q: What are the main challenges in the storage of steel billets?

- The main challenges in the storage of steel billets include maintaining proper environmental conditions, managing space efficiently, ensuring safety measures, preventing corrosion, and minimizing material damage. Firstly, the storage area should be maintained at a controlled temperature and humidity to prevent the steel billets from being exposed to extreme weather conditions, which could lead to rusting, oxidation, or other forms of corrosion. Adequate ventilation is also necessary to prevent the buildup of moisture that could affect the quality of the billets. Secondly, managing space efficiently is crucial in steel billet storage. Billets are often stored in large quantities, so proper organization and stacking methods must be employed to maximize the storage capacity and facilitate easy access to individual billets when needed. Implementing effective inventory management systems can help prevent unnecessary handling and potential damage. Safety measures are another significant challenge in steel billet storage. Due to their heavy weight and potential for sharp edges, it is essential to ensure proper handling and storage procedures to avoid accidents or injuries. Adequate training for personnel and the use of appropriate lifting equipment are necessary to maintain a safe working environment. Corrosion prevention is a critical concern in steel billet storage. Applying protective coatings, such as oil or rust inhibitors, can help shield the billets from moisture and prevent oxidation. Regular inspections and maintenance routines are also necessary to identify and address any signs of corrosion promptly. Lastly, minimizing material damage is crucial in steel billet storage. Proper handling techniques, such as avoiding dropping or dragging the billets, should be followed to prevent deformation or surface damage. Using suitable packaging or padding materials during transportation and storage can also help protect the billets from scratches or other physical impacts. In conclusion, the main challenges in the storage of steel billets revolve around maintaining proper environmental conditions, efficient space management, ensuring safety measures, preventing corrosion, and minimizing material damage. By addressing these challenges effectively, the longevity and quality of the steel billets can be preserved, resulting in enhanced operational efficiency and customer satisfaction.

- Q: How are steel billets used in the production of marine equipment?

- Steel billets are an integral part of the production process for marine equipment. These billets, which are semi-finished steel products, serve as the raw material for manufacturing different components used in the construction of marine equipment such as ships, offshore platforms, and marine structures. Firstly, steel billets are used to create various structural elements of marine equipment, including hulls, decks, and bulkheads. These components provide the strength and stability necessary to withstand the harsh conditions of marine environments. The billets are heated and shaped through processes like rolling, forging, or extrusion to form the desired shapes and sizes of these structural elements. Additionally, steel billets are used to produce propeller shafts, rudders, and other propulsion system components. These parts are crucial for the movement and maneuverability of marine equipment. The billets are machined and further processed to create these specialized components, ensuring their durability and reliability in demanding marine conditions. Moreover, steel billets are employed in the production of marine equipment accessories such as anchors, chains, and mooring systems. These accessories play a vital role in ensuring the stability and safety of vessels and offshore structures. The billets are transformed into the required shapes and sizes through casting, forging, or machining processes to meet the specific requirements of each accessory. Furthermore, steel billets are also utilized in the manufacturing of marine equipment fittings, including valves, pipes, and fittings for fluid and gas systems. These components are essential for the proper functioning of various systems on board vessels, such as fuel, water, and hydraulic systems. The billets are processed and machined to create these fittings, ensuring their compatibility with marine-grade materials and their ability to withstand corrosive marine environments. In summary, steel billets are crucial in the production of marine equipment as they serve as the primary raw material for creating structural elements, propulsion system components, accessories, and fittings. By using steel billets, manufacturers can ensure the strength, durability, and reliability of marine equipment, enabling them to withstand the challenging conditions of the marine environment and ensuring the safety and performance of vessels and offshore structures.

- Q: How are steel billets used in the construction of bridges?

- Due to their exceptional strength and durability, steel billets play a crucial role in bridge construction. These cylindrical pieces of raw steel are heated and shaped into various structural components, such as beams, columns, and girders, which serve as the foundation of bridge structures. The initial step in utilizing steel billets for bridge construction involves heating them in a furnace to make them malleable. Once the desired temperature is reached, the billets are passed through a series of rollers to shape them into the required sections. This process, referred to as hot rolling, guarantees that the steel achieves the necessary strength and structural integrity. Following this, the shaped steel billets undergo further processing and fabrication to form different bridge components. For example, beams are created by cutting and welding steel billets together to form long, horizontal members that bear the weight of the bridge deck. These beams are designed to withstand heavy loads and provide stability to the entire structure. On the other hand, columns are vertical members that transfer the load from the bridge deck to the foundations. Steel billets are shaped and joined together to construct these load-bearing columns, ensuring they possess the required strength to endure compression forces. Girders also play a vital role in bridge construction, serving as horizontal supports that span across the width of the bridge. Steel billets are shaped into girders, which are then fabricated and connected to the bridge's piers or abutments. These girders provide the necessary strength to evenly distribute the weight of the bridge deck. Aside from their strength, steel billets offer several advantages in bridge construction. They possess a high resistance to corrosion, guaranteeing the durability and longevity of the bridge structure. Additionally, steel billets are highly versatile, allowing engineers to create various shapes and sizes, enabling the design of bridges that meet specific project requirements. Overall, steel billets are extensively utilized in bridge construction due to their strength, durability, and versatility. They form the foundation of bridge structures, providing the necessary support and stability to ensure the safe and efficient transportation of people and goods.

Send your message to us

Steel billets Q215 grade hot sale factory price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords