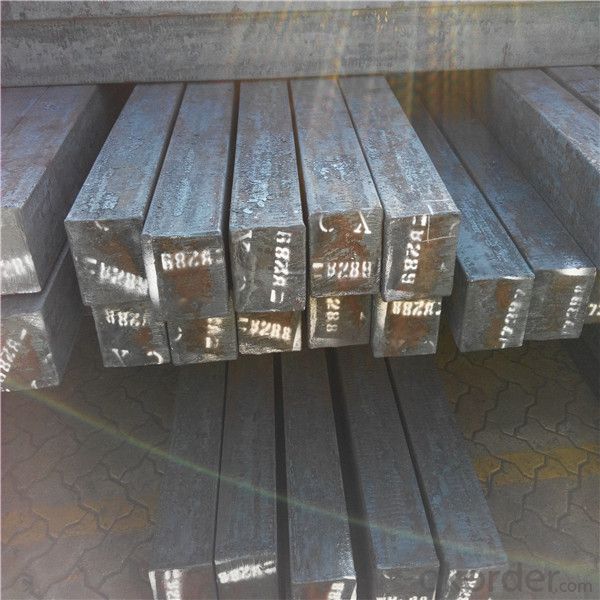

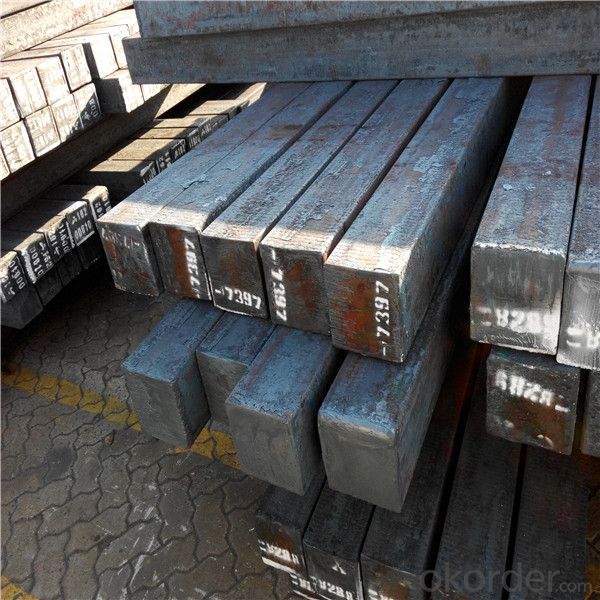

Steel billets Q215 chrome alloy low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14950 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base

building the support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:How is the surface condition of steel billets checked?

- The surface condition of steel billets is typically checked through visual inspection and various non-destructive testing methods. Visual inspection involves thoroughly examining the surface of the billets for any visible defects such as cracks, pits, dents, or scratches. This is usually done by trained inspectors who have a keen eye for detecting surface imperfections. In addition to visual inspection, various non-destructive testing techniques are employed to assess the surface condition of steel billets. These techniques include magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing. Magnetic particle testing involves applying a magnetic field to the billet's surface and then applying fine iron particles. If there are any surface defects, such as cracks or inclusions, the magnetic particles will be attracted to these areas and form visible indications. Liquid penetrant testing involves applying a liquid dye to the surface of the billet. The dye penetrates any surface defects, and after a certain period of time, excess dye is removed, and a developer is applied. The developer draws out the dye from any surface defects, making them visible and easy to detect. Ultrasonic testing utilizes high-frequency sound waves to detect surface and subsurface defects. A transducer is used to generate sound waves that penetrate the billet's surface. If there are any defects, such as cracks or voids, the sound waves will reflect back, and by analyzing the reflected waves, any surface or subsurface flaws can be identified. Eddy current testing involves passing an alternating current through a coil placed near the billet's surface. Any surface defects or variations in the material's conductivity will cause changes in the current flow, which can be detected and analyzed to determine the surface condition. These non-destructive testing methods provide accurate and reliable information about the surface condition of steel billets, helping to ensure their quality and integrity before further processing or usage.

- Q:What is the typical tensile strength of a steel billet?

- The typical tensile strength of a steel billet can vary depending on the specific grade and composition of the steel. However, in general, steel billets have a tensile strength ranging from 370 to 550 megapascals (MPa). This range is commonly found in low to medium carbon steels used for various applications in industries such as construction, automotive, and manufacturing. It is important to note that higher-grade steels, such as alloy steels, can have significantly higher tensile strengths, exceeding 1000 MPa. Ultimately, the tensile strength of a steel billet is determined by its intended application and the specific requirements of the project.

- Q:What are the environmental impacts of producing steel billets?

- The production of steel billets has several environmental impacts. One of the main concerns is the emission of greenhouse gases, particularly carbon dioxide (CO2), during the steelmaking process. Steel production is a significant contributor to global CO2 emissions, as the process requires high temperatures and the use of fossil fuels, such as coal or natural gas, to extract iron from iron ore. The combustion of these fuels releases CO2 into the atmosphere, contributing to climate change. Another environmental impact of steel billet production is the generation of air pollutants. The use of fossil fuels in steelmaking can result in the release of sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter, which contribute to air pollution and can have negative effects on human health. Additionally, the production of steel billets often involves the use of additives and chemicals, which can further contribute to air pollution if not properly managed. The extraction of iron ore, which is a primary raw material for steel production, can also have significant environmental consequences. Mining activities can lead to deforestation, habitat destruction, and soil erosion. Furthermore, the extraction and transportation of iron ore require the use of heavy machinery and vehicles, which consume energy and contribute to air pollution. Water usage is another environmental concern in steel billet production. Steelmaking processes require substantial amounts of water for cooling, cleaning, and dust suppression. The extraction and treatment of water, as well as the discharge of wastewater, can have adverse effects on local water sources, particularly if not properly managed or treated. Lastly, the production of steel billets also generates waste and by-products. Steel slag, a by-product of the steelmaking process, can contain heavy metals and other pollutants. If not properly treated or disposed of, these by-products can contaminate soil and water resources. Overall, the production of steel billets has significant environmental impacts, including greenhouse gas emissions, air pollution, water usage, and the generation of waste and by-products. To mitigate these impacts, efforts are being made to develop cleaner and more energy-efficient steelmaking technologies, increase the use of recycled steel, and improve waste management practices in the industry.

- Q:How are steel billets used in the production of structural sections?

- Steel billets are an essential raw material in the production of structural sections. These sections, such as beams, columns, and girders, are crucial components in the construction industry and are used to create sturdy and durable buildings, bridges, and other infrastructure. To begin the production process, steel billets are heated to extremely high temperatures in a furnace. This process, known as "hot rolling," makes the steel more malleable and easier to shape. Once the billets have reached the required temperature, they are passed through a series of rollers to gradually reduce their thickness and shape them into the desired structural section. The hot rolling process ensures that the steel maintains its strength and structural integrity while being shaped. It also helps to align the grain structure of the steel, resulting in improved strength and ductility. Moreover, the hot rolling process eliminates any internal stresses within the steel, making it less prone to cracking or failure. After the hot rolling process, the structural sections are cooled down and then cut to the desired length. They may also undergo additional treatments, such as straightening or surface finishing, to meet specific requirements or improve their aesthetics. Overall, steel billets play a crucial role in the production of structural sections. By providing the raw material that is shaped and processed, steel billets ensure that the resulting sections possess the necessary strength, durability, and stability required for construction projects.

- Q:How are steel billets used in the production of industrial furnaces?

- Steel billets are an essential component in the production of industrial furnaces. These billets, which are semi-finished steel products, serve as the raw material for manufacturing various furnace components. To begin with, steel billets are used to fabricate the furnace shell or casing, which provides the structural integrity and containment for the furnace. The billets are shaped and welded together to form a sturdy and durable outer shell that can withstand the high temperatures and harsh conditions within the furnace. Moreover, steel billets are used to construct the furnace doors and access panels. These components need to be strong and resistant to deformation and warping caused by the intense heat generated inside the furnace. By using steel billets, manufacturers can ensure that the doors and access panels can be opened and closed easily, while maintaining their structural integrity over time. Furthermore, steel billets are also utilized in the production of furnace grates and supports. These components are responsible for holding and supporting the materials being heated inside the furnace. By using steel billets, manufacturers can create robust and heat-resistant supports that are capable of withstanding heavy loads and high temperatures for extended periods. In addition, steel billets are often used in the fabrication of heat exchangers within industrial furnaces. Heat exchangers are vital for transferring heat from the combustion chamber to the materials being processed. The use of steel billets ensures that the heat exchangers have excellent thermal conductivity and can withstand the corrosive effects of the furnace environment. Overall, steel billets play a crucial role in the production of industrial furnaces by providing the necessary strength, durability, and heat-resistant properties required for their various components. Without steel billets, it would be challenging to manufacture furnaces capable of withstanding the extreme conditions encountered in industrial processes.

- Q:What are the potential applications of steel billets in the chemical sector?

- Steel billets have a wide range of potential applications in the chemical sector. One of the main uses of steel billets is in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets are highly durable and can withstand the corrosive nature of many chemicals, making them ideal for this purpose. Additionally, steel billets can be used in the construction of pipes and tubing systems for chemical processing plants. These pipes and tubing systems are used to transport various chemicals throughout the facility and need to be able to withstand high pressures and temperatures. Steel billets provide the strength and durability required for these applications. Another potential application of steel billets in the chemical sector is in the production of chemical reactors. Chemical reactors are used in the manufacturing of various chemicals and require materials that can handle the harsh conditions involved in chemical reactions. Steel billets can be used to construct these reactors, providing the necessary strength and resistance to corrosion. Furthermore, steel billets can be utilized in the fabrication of various equipment used in the chemical sector, such as heat exchangers, distillation columns, and pumps. These equipment are essential for the processing and production of chemicals, and steel billets provide the necessary strength and reliability required for their operation. Overall, the potential applications of steel billets in the chemical sector are vast and varied. Their durability, strength, and resistance to corrosion make them an ideal choice for various construction and fabrication purposes in chemical processing plants, storage facilities, and equipment manufacturing.

- Q:How are steel billets rolled into rails?

- Steel billets are rolled into rails through a process called hot rolling. This process involves several steps to transform the steel billets into the desired rail shape. Firstly, the steel billets are heated in a furnace to a temperature of around 1200°C. This high temperature makes the steel malleable and easier to shape. Once the billets reach the desired temperature, they are transferred to a rolling mill. In the rolling mill, the heated steel billets are passed through a series of rolling stands. These stands consist of pairs of large rolls that gradually reduce the thickness and shape of the billets. As the billets pass through each stand, the rolls exert immense pressure on the steel, causing it to elongate and take on the characteristics of a rail. As the billets progress through the rolling mill, they are gradually transformed into rails with the desired dimensions. The rolling process also imparts strength and durability to the rails, making them suitable for use in various applications, such as railway tracks. During the rolling process, water or oil is often used to cool the rolls and prevent them from overheating. This cooling also helps in maintaining the desired temperature of the steel billets as they pass through the rolling mill. Once the steel billets have been rolled into rails, they are cut to the desired lengths and subjected to further processing, such as straightening and heat treatment, to ensure the rails meet the required specifications. In summary, steel billets are rolled into rails through the hot rolling process. This involves heating the billets, passing them through a series of rolling stands, and gradually shaping them into rails with the desired dimensions. The resulting rails are then further processed and prepared for use in various applications.

- Q:How are steel billets transported and stored?

- Steel billets are typically transported and stored in a careful and systematic manner to ensure their quality and safety. When it comes to transportation, steel billets are usually moved using trucks or railcars. Trucks are commonly used for short-distance transportation within a steel mill or between different facilities, while railcars are employed for longer distances, including intercity or even international transport. During transportation, steel billets are loaded onto the trucks or railcars using cranes or forklifts. It is crucial to secure the billets properly to prevent any movement or damage during transit. Straps, chains, or other securing methods are used to keep the billets in place and ensure their stability. Once the steel billets reach their destination, they are unloaded using similar lifting equipment. It is important to handle the billets with care during the unloading process to avoid any scratches or dents that could compromise their structural integrity. Regarding storage, steel billets are typically kept in designated areas called billet yards or billet storage facilities. These areas are designed to accommodate the size and weight of the billets and provide easy access for loading and unloading operations. Steel billets are often stored in stacks or piles, with each billet being carefully positioned to maintain stability and prevent any potential accidents. The billets may be organized based on various criteria, such as size, grade, or production date, to facilitate their retrieval when needed. To protect the billets from environmental factors, such as humidity or corrosion, they are often covered with protective coatings or stored in enclosed areas with controlled climate conditions. Additionally, regular inspections and maintenance are carried out to ensure the quality and integrity of the stored billets. Overall, proper transportation and storage procedures are essential to safeguard the steel billets and maintain their quality until they are ready for further processing or use in various industries.

- Q:What is the role of steel billets in the construction of sports facilities?

- The construction of sports facilities heavily relies on steel billets. These semi-finished steel products serve as the primary raw materials for manufacturing various structural components and equipment needed for sports complexes. One crucial use of steel billets in sports facility construction is for producing steel beams and columns. These structural elements provide the necessary support and stability to ensure athlete and spectator safety. Steel billets are melted and shaped into beams and columns, which then form the framework of the sports facility. Furthermore, steel billets are also utilized in fabricating sports equipment such as goalposts, fencing, and handrails. These components require high strength and durability to withstand the physical demands of the sport and extensive use. By using steel billets, these equipment can be manufactured to meet strength standards while ensuring longevity and safety. Additionally, steel billets play a significant role in constructing seating areas and grandstands within sports facilities. The high load-bearing capacity and structural integrity of steel make it an ideal material for supporting large crowds. By using steel billets, seating areas can withstand heavy loads and provide a safe and comfortable environment for spectators. Moreover, steel billets are instrumental in constructing roofing and façade systems. Steel panels made from these billets offer excellent resistance to weathering, corrosion, and fire, making them suitable for outdoor sports facilities. These panels can be fabricated to provide insulation, protection, and aesthetic appeal, enhancing the overall functionality and appearance of the sports complex. In conclusion, steel billets are vital in sports facility construction. From manufacturing structural elements to producing sports equipment and creating seating and roofing systems, steel billets provide the necessary strength, durability, and safety required for such facilities. Their versatility and reliability make them an indispensable component in the construction process, ensuring that sports complexes meet the highest standards of quality and performance.

- Q:What types of steel are commonly used for billets?

- Billets, commonly used in various industries, require different types of steel depending on specific needs and desired properties. For instance, carbon steel is a popular choice due to its affordability, durability, and high strength. It is an alloy of iron and carbon, suitable for applications in construction, automotive, and machinery industries. Alloy steel, on the other hand, involves the addition of alloying elements like chromium, nickel, and molybdenum to carbon steel. This enhances the steel's strength, toughness, and corrosion resistance, making it ideal for demanding applications such as aerospace, oil and gas, and power generation. Stainless steel, known for its corrosion resistance, finds extensive use in billets for applications where protection against corrosion is critical, like marine environments and food processing industries. It is created by adding chromium and other elements like nickel or molybdenum to carbon steel, resulting in excellent resistance to corrosion, high temperatures, and chemicals. Lastly, tool steel is specifically designed for the manufacturing of tools and dies. It contains alloying elements like tungsten, vanadium, or cobalt, providing exceptional hardness, wear resistance, and heat resistance properties. These billets are crucial for producing precision tools and components used in industries like automotive, aerospace, and manufacturing. In conclusion, carbon steel, alloy steel, stainless steel, and tool steel are commonly utilized for billets. The selection of steel depends on the specific requirements of the application, such as strength, corrosion resistance, or hardness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel billets Q215 chrome alloy low price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14950 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords