Geotextile Hanes - Staple Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Properties of Staple fibers needle punched non woven geotextile

Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

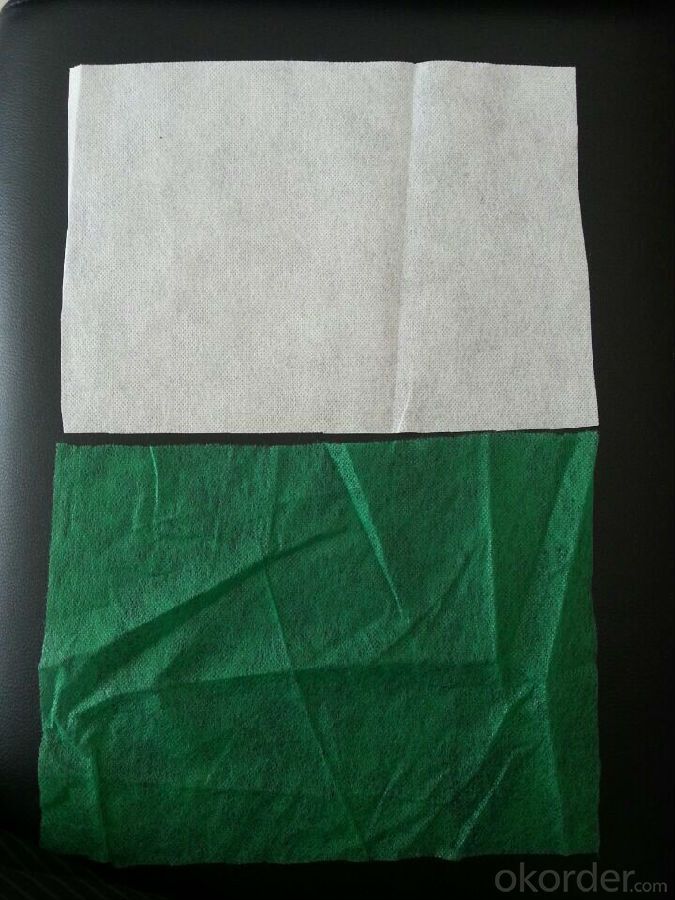

Images of non woven geotextile

- Q: What are the key considerations for geotextile installation in high-altitude regions?

- The key considerations for geotextile installation in high-altitude regions include the selection of materials that can withstand extreme weather conditions, such as low temperatures and high winds. It is important to choose geotextiles with high tensile strength and durability to ensure they can withstand the harsh environment. Additionally, proper anchoring techniques and installation methods should be employed to ensure the geotextiles remain in place and perform their intended functions effectively.

- Q: What are the key considerations for geotextile installation in high water flow areas?

- Some key considerations for geotextile installation in high water flow areas include selecting a geotextile material with a high flow rate to allow for effective water drainage, ensuring proper anchoring and securing of the geotextile to prevent displacement, conducting thorough site investigations and assessments to determine the appropriate installation method and design, and monitoring the performance of the geotextile over time to identify any maintenance or repair needs. Additionally, considering the environmental conditions and potential impact on the geotextile's durability is crucial in high water flow areas.

- Q: On the road where the laying of geotextiles should be how to shop

- Like roadbed fill, fill the junction and so on can be shop, a layer of a layer of shop, fixed good.

- Q: What are the standards and specifications for geotextiles?

- The standards and specifications for geotextiles are defined by various organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Geosynthetic Institute (GSI). These standards cover aspects such as tensile strength, elongation, thickness, permeability, and durability of geotextiles. They also provide guidelines for testing methods, installation practices, and performance requirements to ensure the quality and effectiveness of geotextile products in various applications like soil stabilization, drainage, erosion control, and filtration.

- Q: What is the standard width of geotextile?

- Our company's production is normal 4/6 two specifications.

- Q: How do geotextiles help with soil confinement in erosion control block walls?

- Geotextiles play a crucial role in soil confinement within erosion control block walls by acting as a filter and separator. They prevent soil particles from washing out while allowing water to drain through, thereby reducing hydrostatic pressure and the risk of wall failure. Additionally, geotextiles enhance the overall stability and longevity of the wall by providing reinforcement and preventing soil erosion.

- Q: In the cofferdam construction process, geotextile materials after entering the need to arrange sampling test? Is there a specification? If the arrangements for testing, is to do physical experiments, or do chemical experiments, or do? More

- Physical experiments,

- Q: Polyester filament nonwoven is filament geotextile

- Yes, generally do geotextile material, polyester filament nonwoven fabric refers to filament geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are often used as a protective barrier between the tank and the surrounding soil to prevent erosion, provide stability, and improve the longevity of the tank. They can also help in filtering out sediment and preventing clogging of tanks, ensuring their efficient operation.

- Q: What are the different geotextile puncture resistance test methods?

- There are several different geotextile puncture resistance test methods, including the ASTM D4833 puncture test, ASTM D6241 puncture test, and the ISO 12236 puncture test. These tests involve applying a force to a geotextile specimen using a puncture probe or cone, and measuring the force required to puncture the material. These methods help determine the puncture resistance and durability of geotextiles for various applications.

Send your message to us

Geotextile Hanes - Staple Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords