Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

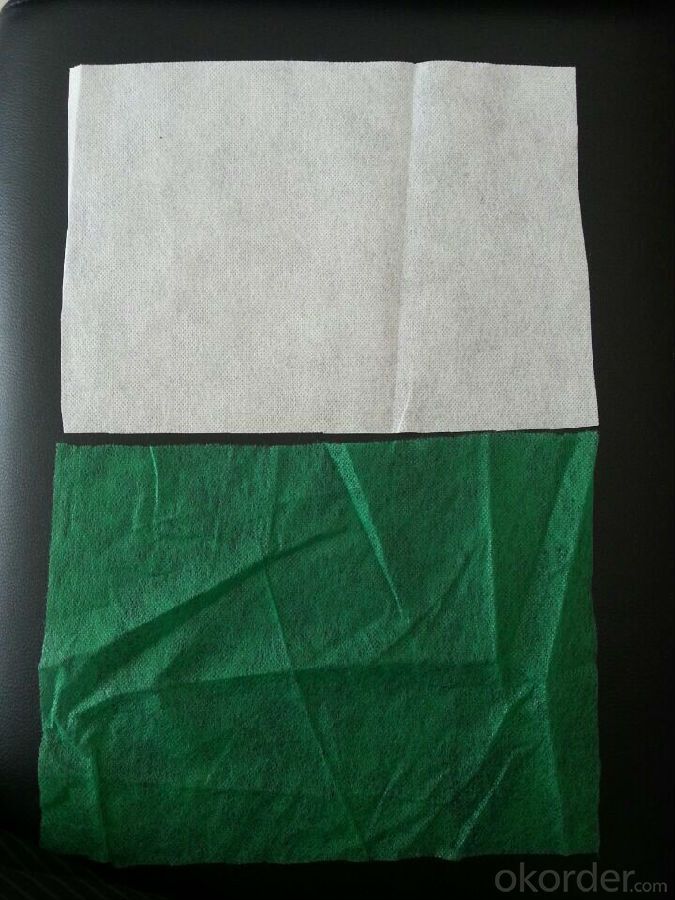

Staple fibers needle punched non woven geotextile

Filament geotextile mainly applied in water conservancy, road, railway, dam and tunnel for separation, filtration, reinforcement and drainage of projects

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

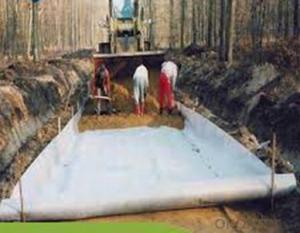

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Specification:100g~800g

Properties of Staple fibers needle punched non woven geotextile

Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

Images of non woven geotextile

- Q: Who can talk about geogrid, fiberglass and geotextile What is the difference, from the material function, use all aspects of speaking, if the answer is good, I will add more points

- (Woo Yu. Friendship Plaza)

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering applications for their ability to provide stability, filtration, and separation. When placed correctly, geotextiles can enhance the strength and durability of bridge abutments by distributing load, preventing soil erosion, and improving overall stability.

- Q: Are geotextiles resistant to freeze-thaw cycles?

- Yes, geotextiles are typically resistant to freeze-thaw cycles. They are designed to withstand extreme weather conditions, including freezing temperatures and repeated cycles of freezing and thawing without significant deterioration or damage.

- Q: What are the specifications for geotextiles in green roof applications?

- Geotextiles used in green roof applications typically have specific specifications such as high tensile strength to withstand the weight of the vegetation and soil, excellent water permeability to allow efficient drainage, UV resistance to withstand prolonged exposure to sunlight, and appropriate thickness to provide adequate protection for the underlying layers of the green roof system.

- Q: How do geotextiles help with soil reinforcement in mechanically stabilized earth walls?

- Geotextiles provide reinforcement to mechanically stabilized earth walls by enhancing their strength and stability. They act as a barrier between the soil and the backfill material, preventing soil erosion and promoting better load distribution. The geotextiles also increase the friction between the soil and the backfill, reducing lateral movement and improving overall structural integrity.

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include the selection of appropriate geotextile material, understanding the slope characteristics, conducting a thorough site investigation, ensuring proper anchoring and securing methods, and collaborating with experienced geotechnical engineers for design and installation guidance. Additionally, considering the long-term performance, maintenance requirements, and monitoring of the geotextile system is crucial to ensure its effectiveness in mitigating landslide risks.

- Q: Can geotextiles be used for filtration purposes?

- Yes, geotextiles can be used for filtration purposes. They are designed to allow water or other liquids to pass through while retaining soil or other particles, making them effective for various filtration applications in areas such as agriculture, construction, and environmental engineering.

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- When selecting geotextiles for riverbank stabilization, several considerations should be taken into account. Firstly, the strength and durability of the geotextile are crucial factors. It should have sufficient tensile strength and resistance to degradation from UV radiation, chemicals, and biological agents. Additionally, the permeability of the geotextile plays a vital role in allowing water to pass through while preventing soil erosion. The geotextile should also be compatible with the soil type and vegetation in the area to ensure proper integration and long-term stability. Finally, the cost-effectiveness and ease of installation should be considered to ensure practicality and efficiency in the riverbank stabilization process.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by acting as a barrier between the soil and water, preventing erosion by filtering and stabilizing the soil. They provide reinforcement and support to the soil, reducing the impact of water flow and preventing the loss of soil particles. Additionally, geotextiles promote vegetation growth by retaining moisture, enhancing root development, and protecting newly seeded areas from wind and water erosion.

- Q: Can geotextiles be used in geotextile wrapped columns?

- Yes, geotextiles can be used in geotextile wrapped columns. Geotextiles are commonly used as a wrapping material for columns in geotechnical engineering applications. They provide reinforcement and confinement to the columns, enhancing their load-bearing capacity and stability. Additionally, geotextiles help prevent soil erosion and facilitate proper drainage, further improving the performance of geotextile wrapped columns.

Send your message to us

Bâche Géotextile - Staple Fibers Needle Punched Non Woven Geotextile with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords