Staple Fiber Needle Punched Geotextile or Non-wovenGeotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of our Geotextile:

Geotextile fabrics

Material:polyester fibre

Width:2-6m

Colour:white or black

Use:road ,highway,filter

Weight:100-1000g/m2

Tensile strength:2.5KN/m-25KN/m

Break elogation:25-100%

Gextextile Product Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

-- It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Product Specification / Models:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1200g/m2

Width: 1-8m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Payment terms: T/T 30% in advance+T/T 70% against the copies of original documents or L/C

PS. Also we can produce the product as customer’s demand.

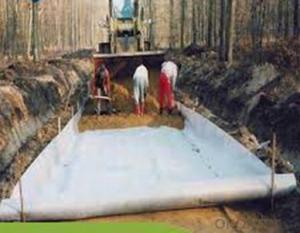

Application of Geoxtile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.20 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (10-1 ~ 10-3) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN ≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

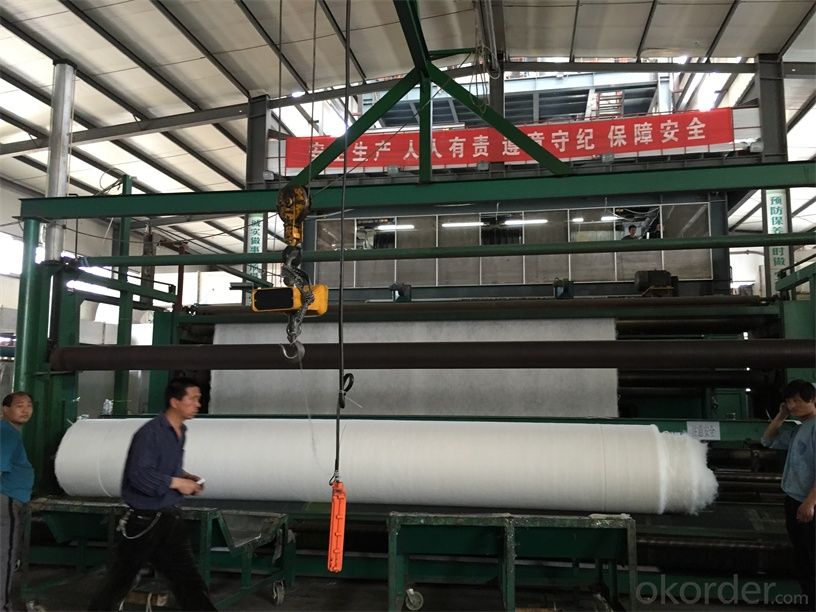

Geotextile Products Show:

FAQ of our geotextile:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: What kind of fabric is polyester fiber with spandex?

- Polyester fiber: polyester; elastic fiber: spandex. Namely: polyester and spandex interwoven fabric. Or wrapped or coated

- Q: What's the fabric of Pearl Chiffon?

- Chiffon is divided into many kinds, pearl Chiffon is a kind of chiffon classification, also known as Chiffon beads, and composite silk chiffon, a little similar texture, can replace each other. After skin contact, there is a cold feeling, very comfortable, sag sense is better than the usual chiffon, twist is relatively high!

- Q: What exactly is the ingredient of iced silk fabric?

- Ice silk is a kind of knitted dress fabric. It is made of 70% mulberry silk and 30% nylon silk by twisting and twisting. It is usually an ecological fiber made from silk and cotton, or a coarse fiber textile. After weaving, the nylon component with thermoplastic property is produced by wet treatment, resulting in a sharp contraction, while viscose is fully exposed to the surface so that the interior is hydrophobic and the exterior is hydrophilic. The dress made of this kind of yarn is cool and comfortable, so it has the name of "ice silk".

- Q: Nylon and polyester which is easy to electrostatic?

- Under normal circumstances, polyester is more easy to electrostatic, of course, whether it is nylon or polyester, if the raw materials used are anti-static treatment, you can not do static.

- Q: What's good about linen?

- In the world, the flax is weaving looms and rapier loom, the company launched a new Shanghai group including delicate linen, shirting, crepe, fancy yarn, sportswear and flax wool fabric products. Household products include curtains, tablecloths, wall cloth, bedding fabrics etc.. Industrial products include: canvas, baggage tents, insulation cloth, filter cloth, and aviation linen products, which will pass the linen culture to every corner of people's life.

- Q: What is the difference between fabric and fabric? What does fabric mean?. What do you mean by material?

- In clothing washing mark, fabric is worn on the outside of the layer, lining is close to the layer, if it is down jacket, down the 1-2 layers called gall cloth, of course, the market down jacket has 2,3,4 several practices.

- Q: The suit is good or Hunfang wool acrylic fabric?

- Acrylic fiber has the name of synthetic wool. Having a soft, bulky, easy to dye, bright color, light, antibacterial, not afraid of insects and other advantages, according to different application requirements can be pure spinning or with natural fiber, the textile is widely used in clothing, decoration industry, etc..

- Q: How to wash silk fabric trousers?

- Silk clothing should be suspended for clothes storage box, cabinet to keep clean and dry, to prevent dust pollution, good sealing, do not sprinkle deodorant or perfume, do not put mothballs. The preservation of thin silk clothing, underwear, shirts, pants, skirts, pajamas, first wash clean, pressed and dried after collection. For the inconvenience and the autumn and winter clothing, jacket, dress to wash clean with dry cleaning, ironing, to prevent mildew and moth. After ironing, can also play the role of sterilizing, ironing clothes drying to seven or eight into dry and then evenly spray water for 3 to 5 minutes, and then hot pressing, temperature should be controlled between 130 degrees to 140 degrees, the iron should not directly touch the silk surface, so as to avoid the aurora, must be on with a layer of wet and hot, to prevent the high temperature to make the silk crisp, even burnt.

- Q: What is the difference between TC fabric and cotton fabric?

- Cotton: cloth made from cotton yarn. It is the floorboard of all kinds of cotton textiles. It is used to make fashionable clothes, casual clothes, underwear and shirts. The utility model has the advantages of easy warm, soft close, hygroscopicity, permeability is very good. It is easily the shortcomings shrinkage, easy to wrinkle, the appearance is neat and elegant, dress must constantly pressing.

- Q: What material is double Zou?

- Soft, elastic, comfortable, cool, breathable, body weight than silk georgette. Shrinkage is larger, about 10%. According to its characteristics, the following methods should be adopted. 1., you need to fall into the water first, after it has shrunk sufficiently, then cut out the clothes. 2. when washing, to avoid the attention of ordinary soap, and use neutral detergent; don't rub vigorously, do not use hair brush; after washing must rinse clean, otherwise prone to flower stalls and banhen; lightly squeeze water, even dry, should not use heavy iron hot rolling so as to avoid evil wrinkles. 3., usually wear should pay attention to avoid contact with rough surface, in order to prevent hook silk fluff, destroy wrinkle organization. 4., storage should be folded, placed in the box, do not hang up for a long time, because crepe silk clothing will be affected by gravity, the longer the hanging, so that the fabric formed by twisting the concave convex shape and telescopic state was damaged. Similar fabric, georgette crepe.

Send your message to us

Staple Fiber Needle Punched Geotextile or Non-wovenGeotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords