6 Oz Staple Fiber Needle Punched Geotextile/Non-Woven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | ROLLED IN PLASTIC BAG |

| Delivery Detail: | 3-5 DAYS |

Specifications

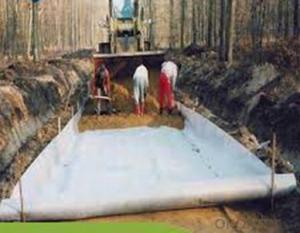

it prevents the bank from being washed out ,protects the bank and the bottom prevents the water and soil from being washed away.

Application of geotextiles

Filtration

Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

Protection

1.Product introduction of geotextile:

1.Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance.

2.Nonwoven Geotextiles are available in varying strengths and thicknesses to ensure appropriate material 3.selection for your project. Custom roll sizes are also available.

4.Nonwoven geotextiles have a wide range of applications in civil environmental engineering and construction projects.

2.Its usage of geotextile:

1 Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of water

2 Separation and stabilization in road and railway construction

3 Prevention of soil movement in erosion control measures

4 Cushioning and protection in many containment projects

FAQ:

♦ Payment terms: by T/T or L/C |

♦ MOQ:2000 SQM |

♦ If you are interested in our products ,pls advice me the technical index,product weight etc,the more information the better..... |

- Q: Can the tunnel longitudinal drains be wrapped with geotextiles and wrapped with a waterproof board?

- With geotextile wrapped drainage pipe is generally played the role of seepage drainage, do not need waterproof board (you said the waterproof board should be geomembrane it) Chong Hong geotextile material manufacturers

- Q: Why do you want to wrap the geotextile

- Hello, geotextile through the water, play the role of filtering Huazhi geotechnical materials manufacturers to answer

- Q: How do geotextiles improve soil stability?

- Geotextiles improve soil stability by providing reinforcement and separation. They prevent soil erosion, retain moisture, and distribute loads, ultimately enhancing the overall strength and stability of the soil.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. Geotextiles are commonly used to reinforce and stabilize soil by providing strength, preventing erosion, and promoting drainage. They are often used in various civil engineering applications such as road construction, embankments, and retaining walls to improve the stability and longevity of the soil.

- Q: How do geotextiles contribute to slope stability analysis?

- Geotextiles play a significant role in slope stability analysis by reinforcing the soil and enhancing its strength. They are used to stabilize slopes by adding tensile strength, reducing soil erosion, and improving overall stability. Geotextiles act as a barrier, preventing the soil particles from washing away during rainfall or other external forces. This helps to mitigate potential slope failures and allows for more accurate analysis and assessment of slope stability.

- Q: What are the factors that affect the strength of geotextiles?

- The strength of geotextiles can be affected by several factors such as the type and quality of materials used, the manufacturing process, the weight and thickness of the geotextile, the presence of any coatings or treatments, and the installation and environmental conditions in which the geotextile is used.

- Q: Are geotextiles suitable for use in landfill applications?

- Yes, geotextiles are suitable for use in landfill applications. They are commonly used as a protective layer to separate different materials in landfills, providing filtration and drainage capabilities. Geotextiles help prevent the mixing of waste materials, facilitate leachate collection, and enhance overall stability and performance of landfills.

- Q: Geotextile with glue can stick cement wall

- There is a special geomembrane ks glue, I am specializing in the production of geotechnical materials

- Q: Welding geotextile how to apply the mattress on or below

- The company specializes in the production of geotextile, geomembrane and other geotextile materials to undertake welding works!

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed along the slope to prevent soil erosion and promote stability. The geotextiles act as a barrier, preventing the movement of soil particles and reducing the risk of slope failure. Additionally, they enhance the soil's strength and increase its resistance to erosion caused by water flow. Overall, geotextiles play a crucial role in maintaining the stability of slopes during pipeline construction.

Send your message to us

6 Oz Staple Fiber Needle Punched Geotextile/Non-Woven Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords