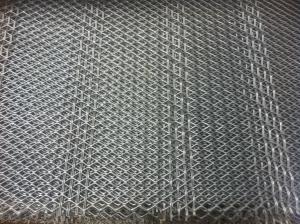

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q: What is hot rolled steel pipe? What is a cold drawn steel tube?

- Overview of two processesHot-rolled (extrusion seamless pipe): billet, heating, perforation, three roll cross rolling, rolling or extrusion, tube to tube diameter (or reducing) - cooling - tube, straightening, pressure test (or testing), marking and warehousing.Cold drawing (rolling) seamless steel pipe: round tube to heating to perforation, annealing, pickling, leading to oil (copper), multi pass drawing (Leng Zha), the blank pipe, heat treatment, straightening, pressure test (testing), marking and warehousing.

- Q: What are the advantages of using steel pipes over other materials?

- Using steel pipes instead of other materials has several advantages: 1. Exceptional strength and durability: Steel pipes have the ability to withstand high pressure, heavy loads, and extreme weather conditions. This makes them suitable for various uses, such as transporting fluids and gases, providing structural support, and laying underground pipelines. 2. Enhanced resistance to corrosion: Steel pipes can be coated with different materials to increase their resistance to corrosion. This makes them ideal for transporting corrosive substances like water and chemicals without the risk of pipe degradation. Additionally, steel pipes are less prone to rust, which prolongs their lifespan. 3. Long-term cost-effectiveness: Although the initial cost of steel pipes may be higher than other materials, they offer long-term cost-effectiveness. Due to their durability and resistance to corrosion, steel pipes require less maintenance and replacement, resulting in reduced operational costs over time. 4. Versatility: Steel pipes come in various sizes, shapes, and thicknesses, making them versatile for different applications. They can be easily customized and fabricated to meet specific requirements, such as bending, welding, and threading. 5. Fire resistance: Steel pipes have a high melting point, making them resistant to fire and reducing the risk of structural damage in case of a fire incident. This characteristic is particularly important in industries where fire safety is crucial, such as oil and gas, chemical, and construction. 6. Environmentally friendly: Steel is a recyclable material, and steel pipes can be recycled and reused multiple times without compromising their quality. This not only reduces the demand for new materials but also contributes to environmental sustainability. 7. Excellent flow characteristics: Steel pipes have smooth internal surfaces, minimizing friction and allowing for efficient flow of fluids and gases. This advantage is particularly significant in industries where fluid dynamics and energy efficiency are essential, such as oil and gas, water supply, and HVAC systems. In conclusion, steel pipes offer numerous advantages over other materials, including strength, durability, corrosion resistance, cost-effectiveness, versatility, fire resistance, eco-friendliness, and excellent flow characteristics. These advantages make steel pipes the preferred choice for a wide range of applications in various industries.

- Q: How do steel pipes handle extreme temperatures?

- Steel pipes are designed to handle extreme temperatures due to their high thermal conductivity and resistance to heat. At high temperatures, steel pipes expand but maintain their structural integrity, preventing them from warping or weakening. Additionally, steel's low thermal expansion coefficient allows it to withstand rapid temperature changes without significant damage. Overall, steel pipes are well-suited for transporting hot or cold fluids and gases in various industrial applications.

- Q: What is the elasticity of steel pipes?

- Steel pipes exhibit elasticity, which allows them to undergo deformation when external forces are applied and regain their original shape once the force is no longer present. The high elasticity of steel pipes is well-known, as it enables them to endure different types of stress and strain without suffering permanent deformation. This characteristic is vital in situations where pipes experience pressure, bending, or other mechanical forces. The elasticity of steel pipes is determined by material properties like its Young's modulus, which quantifies its stiffness and capacity to resist deformation.

- Q: What are the properties of steel that make it suitable for pipe manufacturing?

- Due to its unique properties, steel is highly favored as a material for manufacturing pipes. The exceptional strength and durability of steel allow it to withstand high pressure and extreme temperatures, ensuring the safe transportation of fluids and gases over long distances without the risk of leakage or breakage. Another significant advantage of steel is its resistance to corrosion. Unlike other materials that can degrade when exposed to corrosive substances such as water, chemicals, and gases, steel remains highly resistant to corrosion. This quality makes steel pipes long-lasting and reliable. Furthermore, steel is a versatile material that allows for the production of pipes in various sizes and shapes. This flexibility enables customization to meet specific project requirements, making steel pipes suitable for a wide range of applications, including water supply, oil and gas transmission, sewage systems, and structural support. Moreover, steel possesses excellent thermal conductivity, which is crucial for applications involving the transportation of hot or cold fluids. Steel pipes efficiently transfer heat, ensuring minimal energy loss during the process. Additionally, steel is an environmentally friendly option for pipe manufacturing due to its recyclability. Steel pipes can be recycled and reused, reducing the demand for new raw materials and minimizing waste generation. In conclusion, the properties of strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability make steel the ideal choice for pipe manufacturing. These properties guarantee the reliability, efficiency, and longevity of steel pipes in various industries and applications.

- Q: Can steel pipes be used for underground telecommunications networks?

- Yes, steel pipes can be used for underground telecommunications networks. Steel pipes are commonly used for their durability, strength, and resistance to corrosion, making them suitable for protecting and housing telecommunication cables underground. They provide reliable protection against external elements and mechanical damage, ensuring the smooth operation of underground telecommunications networks.

- Q: What are the environmental impacts of steel pipe production?

- The environmental impacts of steel pipe production include the extraction of raw materials (iron ore, coal, and limestone) which leads to habitat destruction and soil erosion. The manufacturing process requires significant energy, contributing to greenhouse gas emissions and air pollution. Additionally, the production generates waste materials, such as slag and by-products, that can contaminate water sources if not properly managed. Finally, the transportation of steel pipes adds to carbon emissions and can disrupt ecosystems if not done sustainably.

- Q: What are the safety precautions while working with steel pipes?

- Some safety precautions while working with steel pipes include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, using proper lifting techniques to prevent back injuries, ensuring the work area is well-lit and free of obstacles, and using the correct tools and equipment for the job. Additionally, it is important to follow proper safety procedures when handling and storing steel pipes to minimize the risk of accidents or injuries.

- Q: Can steel pipes be used for underground gas storage?

- Yes, steel pipes can be used for underground gas storage. Steel pipes are commonly used in underground gas storage facilities due to their strength, durability, and resistance to corrosion. They provide a reliable and secure means of storing and transporting gas underground.

- Q: How do steel pipes perform in high-temperature applications?

- Steel pipes perform well in high-temperature applications due to their excellent heat resistance and durability. They can withstand elevated temperatures without deforming or losing their structural integrity, making them ideal for transporting hot fluids or gases in industrial processes. Additionally, steel pipes have low thermal expansion, ensuring their dimensional stability under extreme heat conditions.

Send your message to us

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords