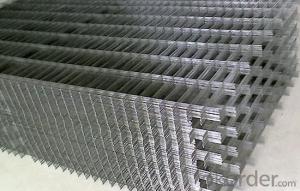

Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Material: | Type: | |||

| Application: | Weave Style: | Wire Diameter: | |||

| Technique: | Model Number: | Brand Name: | |||

| product name(stainless steel mesh): | stainless steel wire mesh usage: | stainless steel mesh other using: | |||

| stainless steel net characteristic: | stainless steel net other characteristic: | Stainless steel mesh deep processing: | |||

| Stainless steel net Further processing: | Stainless steel wire mesh weave: | Stainless steel wire mesh: | |||

| Stainless steel wire mesh wire diameter: |

Packaging & Delivery

| Packaging Detail: | packing:waterproof paper inside, plastic film outside, then pallet or wooden box. Stainless Steel Wire Cloth |

| Delivery Detail: | 10-15 day Stainless Steel Wire Cloth |

Specifications

Stainless Steel Wire Cloth

stainless steel mesh use very broad

wire mesh/filte net/wire cloth

Texture/SS304,316,430,201,320

- Q: What are the different color options available for steel wire mesh?

- The different color options available for steel wire mesh typically include black, silver, and sometimes white or gray.

- Q: What are the benefits of using steel wire mesh in the agriculture industry?

- Using steel wire mesh in the agriculture industry offers numerous advantages. To begin with, it boasts exceptional durability and strength, ensuring optimal safeguarding of crops and livestock against harsh elements like strong winds and heavy rainfall. Furthermore, steel wire mesh serves as a highly effective deterrent against pests and predators. By constructing fences and enclosures, it effectively prevents animals from damaging or consuming crops. While it keeps larger creatures out, it still allows the passage of air and sunlight, creating an ideal growth environment. In addition, steel wire mesh is incredibly versatile and applicable to various agricultural needs. It can be utilized to construct protective cages for poultry and livestock, ensuring their safety without compromising proper ventilation. Moreover, it is frequently employed as trellis support for climbing plants, promoting healthier growth and optimizing space usage. Moreover, steel wire mesh offers cost-effectiveness and requires minimal maintenance. Once installed, it demands little upkeep and boasts a long lifespan, reducing the necessity for frequent replacements. Consequently, it proves to be a budget-friendly option for farmers and agricultural enterprises. Lastly, steel wire mesh is environmentally conscious. It is recyclable and can be repurposed for other applications, thus minimizing waste and contributing to sustainable agricultural practices. In conclusion, the utilization of steel wire mesh in the agriculture industry grants benefits such as durability, protection against pests and predators, versatility, cost-effectiveness, and eco-friendliness. These advantages make it an ideal choice for farmers and agricultural businesses seeking to enhance productivity and safeguard their valuable assets.

- Q: How is steel wire mesh used in reinforcement of chemical plants?

- Steel wire mesh is commonly used in the reinforcement of chemical plants to provide structural integrity and enhance safety. It is typically utilized in concrete or masonry structures to prevent cracking and increase resistance to external forces, such as chemical spills or explosions. The steel wire mesh acts as a reinforcement material, distributing and supporting the loads across the structure, ensuring its durability and longevity in harsh chemical environments.

- Q: What are the standard sizes of steel wire mesh?

- The standard sizes of steel wire mesh vary depending on the application and industry. However, some common standard sizes include 4x8 feet, 5x10 feet, and 6x12 feet. Additionally, wire mesh is available in various wire diameters and mesh opening sizes to suit specific needs and requirements.

- Q: Is steel wire mesh suitable for use in mining or quarrying operations?

- Without a doubt, steel wire mesh proves to be a fitting option for utilization in mining and quarrying endeavors. Renowned for its robustness, endurance, and ability to withstand deterioration, this material is perfectly suited for the demanding conditions and heavy loads associated with mining and quarrying activities. In the realm of mining and quarrying, steel wire mesh is widely employed for diverse purposes. It serves as a reliable support structure for walls, roofs, and tunnels, ensuring stability and reinforcement. Additionally, it acts as a safety precaution, effectively preventing the occurrence of accidents caused by loose rocks or debris falling. Furthermore, steel wire mesh finds utility as a screening material in mining and quarrying undertakings. It facilitates the segregation of rocks, minerals, or other substances of varying sizes, thereby enabling efficient processing and sorting. The mesh's open design facilitates the unhindered passage of water, air, and fluids, a crucial factor in numerous mining and quarrying processes. Moreover, steel wire mesh exhibits remarkable resistance to extreme temperatures, chemicals, and corrosive surroundings, rendering it suitable for deployment across a broad spectrum of mining and quarrying operations. Its immunity to rust and corrosion ensures durability, even amidst challenging conditions. In conclusion, it is evident that steel wire mesh is exceedingly well-suited for mining and quarrying endeavors. Its strength, durability, resistance to wear and tear, and versatility render it an exceptional choice for multifarious applications within these industries.

- Q: Is steel wire mesh suitable for rooftop solar panel installations?

- Rooftop solar panel installations can make use of steel wire mesh, depending on the specific circumstances and requirements. Steel wire mesh is a durable and strong material that offers stability and support for solar panels, effectively securing them in place. It serves as a protective barrier, safeguarding against potential damage from external elements such as strong winds or falling debris. Moreover, steel wire mesh promotes proper ventilation and airflow beneath the solar panels, thereby preventing overheating and enhancing their overall performance. Nevertheless, it is crucial to consider the mesh's type, thickness, as well as the solar panels' weight and size to ensure compatibility and structural integrity. It is highly recommended to seek guidance from a professional installer or engineer to determine the most suitable materials and installation techniques for rooftop solar panel projects.

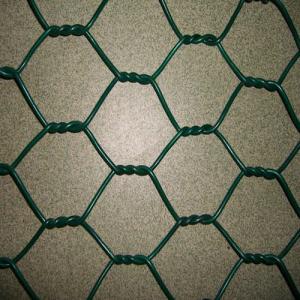

- Q: What are the different types of weaves available for steel wire mesh?

- There are several types of weaves available for steel wire mesh, including plain weave, twill weave, Dutch weave, and reverse Dutch weave.

- Q: What are the maintenance requirements for steel wire mesh?

- The maintenance requirements for steel wire mesh are relatively minimal, but it is still important to regularly inspect and clean the mesh to ensure its longevity and functionality. Here are some key maintenance requirements for steel wire mesh: 1. Regular cleaning: Steel wire mesh should be cleaned regularly to remove any dirt, debris, or other contaminants that may accumulate on its surface. This can be done by simply using a brush or a cloth to wipe away the dirt. For more stubborn stains, a mild detergent or a non-abrasive cleaner can be used. 2. Rust prevention: Steel wire mesh is susceptible to rust, especially if it is exposed to moisture or corrosive substances. To prevent rust formation, it is essential to keep the mesh dry and avoid contact with substances that can promote corrosion. Applying a protective coating, such as paint or a rust-resistant spray, can also help in preventing rust formation. 3. Inspection for damages: Regularly inspecting the steel wire mesh for any damages, such as tears, holes, or loose connections, is crucial to maintain its structural integrity. Any damages should be repaired promptly to prevent further deterioration and potential safety hazards. 4. Lubrication: If the steel wire mesh contains moving parts, such as hinges or joints, lubrication may be necessary to ensure smooth operation. Applying a lubricant specifically designed for metal surfaces can help reduce friction and prevent wear and tear. 5. Protection from extreme weather conditions: Steel wire mesh should be protected from extreme weather conditions, such as heavy rain, snow, or prolonged exposure to direct sunlight. This can be achieved by installing a cover or shelter to shield the mesh from these elements. By following these maintenance requirements, steel wire mesh can remain in good condition and continue to serve its intended purpose effectively and safely.

- Q: What are the environmental benefits of using steel wire mesh?

- The environmental benefits of using steel wire mesh include its durability, recyclability, and low maintenance requirements. Steel wire mesh is resistant to harsh weather conditions and does not deteriorate easily, reducing the need for frequent replacements. Additionally, steel is a highly recyclable material, meaning that steel wire mesh can be repurposed or melted down for future use, reducing waste and conserving resources. Lastly, steel wire mesh generally requires low maintenance, resulting in less energy, water, and chemical usage compared to other materials.

Send your message to us

Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords