Stainless Steel Sheet/Plate 309 with High Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 309 with High Temperature Resistance

Description of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Main Features of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

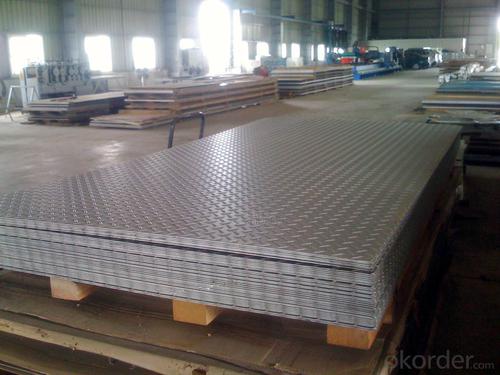

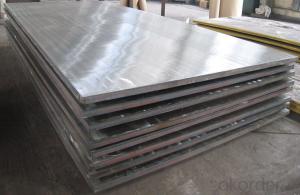

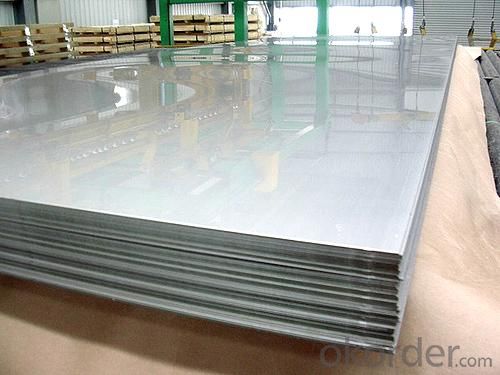

Images of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What is the coefficient of expansion of stainless steel sheets?

- The coefficient of expansion of stainless steel sheets can vary depending on the specific grade or alloy of stainless steel being used. However, in general, stainless steel has a coefficient of expansion ranging from 10.8 to 16.3 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, stainless steel sheets will expand by approximately 10.8 to 16.3 millionths of their original length. It is important to note that different grades of stainless steel may have slightly different coefficients of expansion, so it is always recommended to consult the manufacturer or specific material specifications for accurate information.

- Q: What is the difference between brushed and polished stainless steel sheets?

- The main difference between brushed and polished stainless steel sheets lies in their surface finish. Brushed stainless steel sheets have a textured, linear pattern created by brushing the surface with abrasive materials, giving it a matte appearance. On the other hand, polished stainless steel sheets have a smooth, reflective surface achieved by polishing the steel with a fine abrasive compound.

- Q: Are stainless steel sheets suitable for elevator wall panels?

- Indeed, elevator wall panels can be made from stainless steel sheets. The use of stainless steel is quite popular for such panels due to its strong and enduring nature, as well as its ability to resist corrosion. Given that elevators are areas with high foot traffic, it is crucial to select a material that can withstand constant usage and potential impact. Stainless steel sheets are resilient and can endure the wear and tear associated with elevator usage. Moreover, stainless steel possesses a remarkable resistance to corrosion, making it a suitable choice for environments that experience high humidity or exposure to chemicals. Furthermore, stainless steel adds a sleek and contemporary touch to the interior of elevators, enhancing their elegance. Overall, stainless steel sheets are a dependable and visually pleasing option for elevator wall panels.

- Q: Can stainless steel sheets be used for wire mesh?

- Yes, stainless steel sheets can be used for wire mesh. Stainless steel is a versatile material that is commonly used in various applications due to its durability, corrosion resistance, and strength. When stainless steel sheets are processed into wire mesh, they can provide a strong and reliable mesh structure. Stainless steel wire mesh is often used in industries such as construction, agriculture, mining, and filtration, among others. It is known for its ability to withstand harsh environments, resist rust and corrosion, and maintain its structural integrity over time.

- Q: How do I select the appropriate thickness for stainless steel sheets?

- To select the appropriate thickness for stainless steel sheets, you need to consider factors such as the application, desired durability, strength requirements, and cost. Thicker sheets are generally more durable and offer higher strength, but they may also be more expensive. It is advisable to consult with a stainless steel supplier or industry expert who can assess your specific needs and provide guidance on the most suitable thickness for your project.

- Q: How do I install stainless steel sheets?

- To install stainless steel sheets, you will need to follow a few steps: 1. Measure and prepare the area: Start by accurately measuring the area where you want to install the stainless steel sheets. Use a tape measure to determine the length and width of the space. Additionally, make sure the surface is clean, dry, and free from any debris or contaminants. 2. Cut the sheets: If the stainless steel sheets you have purchased are not already pre-cut to the desired size, you will need to cut them to fit the area. Use a metal cutting saw, such as a circular saw or an angle grinder with a metal-cutting blade, to make precise cuts. Make sure to wear safety goggles and work gloves while cutting to protect yourself from any flying debris. 3. Apply adhesive or screws: Depending on the method you prefer, you can either use an adhesive or screws to secure the stainless steel sheets to the surface. If you choose to use an adhesive, apply a thin layer of construction adhesive to the back of the sheet and press it firmly onto the surface. For added security, you can also use screws to fasten the sheets. Pre-drill holes into the stainless steel sheets and then screw them into place using stainless steel screws. 4. Secure the edges: Once the sheets are in place, secure the edges by using trim pieces or stainless steel molding. This will give your installation a clean and finished look while also providing additional protection to the edges of the sheets. 5. Clean and maintain: After the installation is complete, clean the stainless steel sheets using a mild detergent and a soft cloth. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. Regular cleaning and maintenance will help preserve the appearance and longevity of the stainless steel sheets. Remember, if you are unsure about any step of the installation process, it is always recommended to consult a professional or seek guidance from the manufacturer of the stainless steel sheets you have purchased.

- Q: How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q: What is the thickness range available for stainless steel sheets?

- The thickness range available for stainless steel sheets typically varies from 0.4mm to 6mm, depending on the specific requirements and applications.

- Q: Are stainless steel sheets suitable for food preparation surfaces?

- Stainless steel sheets are highly suitable for food preparation surfaces, making them a top pick for kitchen countertops, cutting boards, and other areas where food is prepared. The many advantageous properties of stainless steel contribute to its popularity. Firstly, it is non-porous, meaning it does not absorb smells, flavors, or bacteria. This characteristic ensures high levels of hygiene and easy cleaning, reducing the risk of cross-contamination. Additionally, stainless steel is resistant to corrosion, staining, and heat, making it a long-lasting and durable option. Its smooth surface is also perfect for rolling out dough or chopping ingredients. Moreover, stainless steel is non-reactive, so it does not interact with acidic or alkaline foods, preserving the taste and quality of the prepared dishes. All in all, stainless steel sheets are an exceptional choice for food preparation surfaces due to their cleanliness, durability, and food safety qualities.

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets typically ranges from 190 to 220 gigapascals (GPa).

Send your message to us

Stainless Steel Sheet/Plate 309 with High Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords