Stainless Steel Plate 409L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Stainless Steel Plate 409L with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

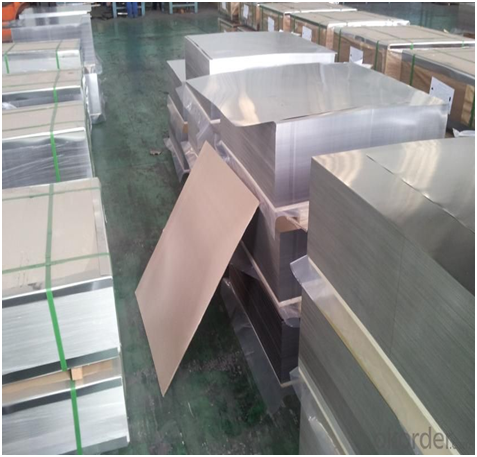

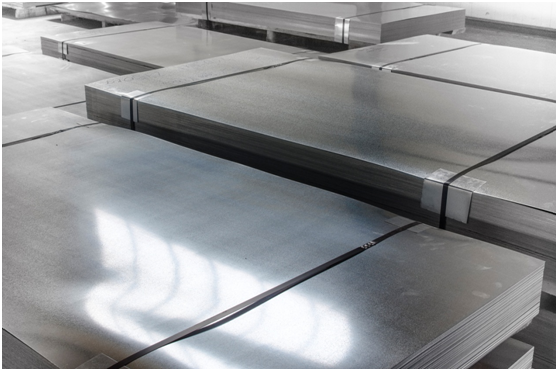

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, there are several steps you can take: 1. Keep the surface clean: Regularly clean the stainless steel sheets using a mild detergent or stainless steel cleaner. This will help remove any dirt, grime, or contaminants that could lead to corrosion. 2. Avoid abrasive cleaners: Avoid using harsh or abrasive cleaners, as they can scratch the surface of the stainless steel, making it more susceptible to rusting. Stick to non-abrasive cleaning solutions and soft cloths or sponges. 3. Remove rust promptly: If you notice any signs of rust on the stainless steel sheets, it is important to address it immediately. Use a stainless steel cleaner or a mixture of vinegar and water to gently remove the rust. Rinse thoroughly and dry the surface afterwards. 4. Protect against moisture: Stainless steel is resistant to rust, but it can still corrode in the presence of moisture. To prevent this, ensure that the stainless steel sheets are properly installed and sealed to protect against water or moisture infiltration. Avoid leaving standing water on the surface and promptly dry any spills or moisture. 5. Apply a protective coating: Consider applying a protective coating to the stainless steel sheets to provide an extra layer of protection against rust. There are various sealants and coatings available specifically designed for stainless steel that can help prevent corrosion. 6. Regular maintenance: Regularly inspect the stainless steel sheets for any signs of damage, rust, or corrosion. Address any issues promptly to prevent further damage. Additionally, perform routine cleaning and maintenance to keep the surface in optimal condition. By following these preventive measures, you can significantly reduce the chances of rusting on stainless steel sheets and maintain their longevity and aesthetic appeal.

- Q: Stainless steel plate how to distinguish between good and bad, there are several thick?

- 1. identification of imported or steel ordered stainless steel materials, usually only in accordance with the import or steel quality certificate, check the steel or packaging on the mark can be.The certificate of quality is the confirmation and guarantee of the inspection result of the product by the supplier. Therefore, the certificate of quality not only indicates the name, specifications, delivery number, weight and delivery status of the materials, but also the entire inspection results of the required guarantee items.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To avoid the presence of fingerprints or smudges on stainless steel sheets, there are several simple steps that can be taken: 1. Regularly clean the surface: Regularly wiping the stainless steel sheets with a soft cloth or microfiber cloth can help prevent the accumulation of fingerprints and smudges. 2. Utilize mild soap and water: Create a mixture of warm water and a few drops of mild dish soap. Dip the cloth into this solution and gently wipe the stainless steel surface in the direction of the grain. This will eliminate any dirt or oil that may attract fingerprints. 3. Thoroughly dry: After cleaning, ensure that the stainless steel sheets are completely dry by using a clean, dry cloth. This will prevent the occurrence of water spots or streaks that can give the surface a smudged appearance. 4. Avoid abrasive cleaning agents or tools: Refrain from using harsh chemicals, abrasive cleaners, or scrub brushes as they can harm the stainless steel finish, making it more susceptible to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths in order to preserve the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Applying a stainless steel cleaner or polish can establish a protective barrier on the surface, rendering it more resistant to fingerprints and smudges. Adhere to the instructions provided with the product and use a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you are aware that your hands tend to leave fingerprints easily, it may be beneficial to wear gloves while handling stainless steel sheets. This precautionary measure can prevent direct contact with the surface and diminish the likelihood of leaving smudges. By adhering to these suggestions, the cleanliness and luster of your stainless steel sheets can be maintained, thereby preventing fingerprints and smudges from diminishing their appearance.

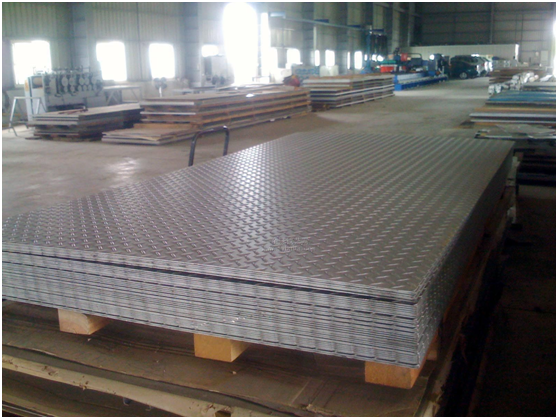

- Q: What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, including plain, diamond, quilted, and hammered. Plain patterns have a smooth, flat surface, while diamond patterns feature raised diamond-shaped ridges. Quilted patterns have a decorative quilt-like design, and hammered patterns have a textured, hammered appearance. These various patterns offer different aesthetic options for stainless steel sheets.

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- There are several different types of embossed patterns available for stainless steel sheets. Some of the most common patterns include: 1. Diamond pattern: This pattern features a series of diamond-shaped raised protrusions on the surface of the stainless steel sheet. It is a popular choice for adding visual interest and texture to various applications. 2. Linen pattern: The linen pattern is characterized by a series of parallel lines that create a textured appearance resembling linen fabric. This pattern is often used in architectural and interior design applications. 3. Squares pattern: As the name suggests, this pattern consists of a series of square-shaped raised protrusions on the stainless steel sheet. It provides a clean and modern look, making it suitable for many different applications. 4. Leather pattern: This embossed pattern mimics the texture and appearance of leather. It adds a touch of elegance and sophistication to stainless steel sheets, making it a popular choice for decorative purposes. 5. Moire pattern: The moire pattern features a wavy or rippled design that creates an optical illusion effect. It adds a unique and dynamic visual element to stainless steel sheets, making them stand out in various applications. 6. Checkerplate pattern: This pattern is characterized by a series of raised squares or rectangles arranged in a checkered pattern. It is commonly used for its high slip resistance, making it ideal for applications where safety is a concern, such as stairs or ramps. These are just a few examples of the many different embossed patterns available for stainless steel sheets. The choice of pattern depends on the desired aesthetic, functionality, and specific application requirements. Whether it's for architectural, interior design, or industrial purposes, there is a wide range of embossed patterns to choose from to meet various needs.

- Q: What is the corrosion resistance of stainless steel sheets?

- Stainless steel sheets possess excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface, preventing the metal from rusting or corroding in various environments.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion. This is because stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the metal from coming into contact with corrosive elements in the environment. However, in certain conditions, such as exposure to high temperatures or welding processes, the chromium in stainless steel can be depleted, leading to the formation of chromium carbides at the grain boundaries. This can result in intergranular corrosion, also known as sensitization. To mitigate this, stainless steel sheets can be treated through a process called stabilization, which involves adding elements like titanium or niobium to the steel to bind with the carbon and prevent the formation of chromium carbides. Overall, stainless steel sheets are highly resistant to intergranular corrosion, but precautions should be taken in specific situations to maintain their corrosion-resistant properties.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a highly durable and versatile material that is commonly used in various applications, including signage. It offers excellent resistance to corrosion, making it suitable for both indoor and outdoor use. Stainless steel sheets can be easily fabricated and cut into different shapes and sizes, allowing for the creation of customized signage and lettering designs. Additionally, stainless steel has a sleek and modern appearance, making it an attractive option for signage in commercial or professional settings. Overall, stainless steel sheets provide a reliable and long-lasting solution for signage and lettering needs.

- Q: What are the advantages of using stainless steel sheets in the aerospace industry?

- There are several advantages of using stainless steel sheets in the aerospace industry. Firstly, stainless steel is known for its exceptional strength and durability. It can withstand high temperatures and extreme conditions, making it ideal for aircraft components that require superior performance and longevity. This strength allows stainless steel sheets to resist corrosion, which is crucial in an industry where safety is of utmost importance. Secondly, stainless steel sheets offer excellent resistance to impact and fatigue. This is particularly vital in the aerospace industry, where components are subjected to constant vibrations and stress. Stainless steel can absorb these forces without compromising its structural integrity, ensuring the safety and reliability of the aircraft. Thirdly, stainless steel sheets have a high strength-to-weight ratio, making them lightweight yet strong. This is crucial in aviation, where reducing weight is a primary concern for fuel efficiency and overall performance. By using stainless steel sheets, aircraft manufacturers can achieve the desired strength without adding unnecessary weight, contributing to improved fuel economy and increased payload capacity. Furthermore, stainless steel sheets are highly versatile. They can be easily formed, welded, and machined into complex shapes and sizes, allowing for the production of intricate aerospace components. This versatility enables engineers to design and manufacture innovative aircraft parts, leading to improved aerodynamics, reduced drag, and enhanced overall performance. Lastly, stainless steel sheets have excellent heat resistance properties. They can withstand high temperatures without losing their strength or shape, making them suitable for applications that involve exposure to extreme heat, such as jet engines or exhaust systems. This heat resistance ensures the longevity and reliability of these critical components, contributing to the overall safety and efficiency of aircraft. In conclusion, the advantages of using stainless steel sheets in the aerospace industry are their exceptional strength and durability, resistance to impact and fatigue, high strength-to-weight ratio, versatility in manufacturing complex components, and excellent heat resistance properties. These qualities make stainless steel sheets an ideal choice for aircraft manufacturers, ensuring the safety, reliability, and efficiency of aerospace vehicles.

- Q: Can stainless steel sheets be used for architectural purposes?

- Yes, stainless steel sheets can be used for architectural purposes. This material is highly versatile and offers excellent durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as facades, cladding, roofing, and decorative features. Stainless steel sheets can be shaped, formed, and finished to meet various design requirements, making them suitable for both functional and decorative architectural elements.

Send your message to us

Stainless Steel Plate 409L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords