Stainless Steel Plate 309S with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Stainless Steel Plate 309S with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

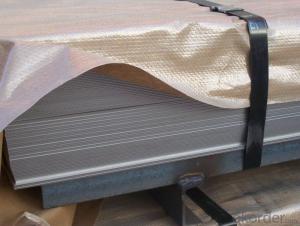

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

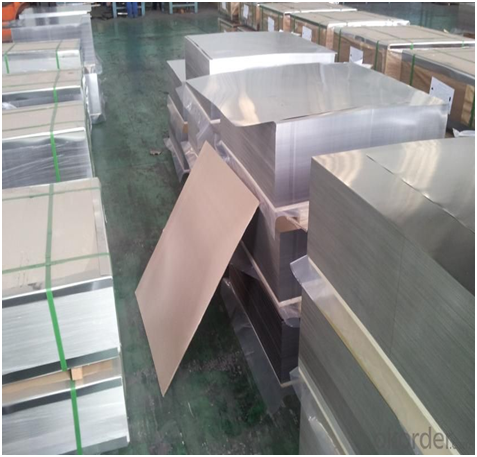

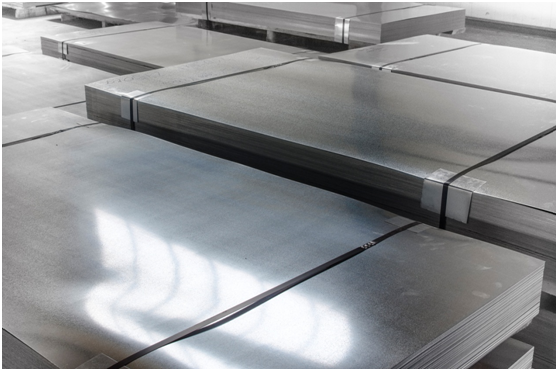

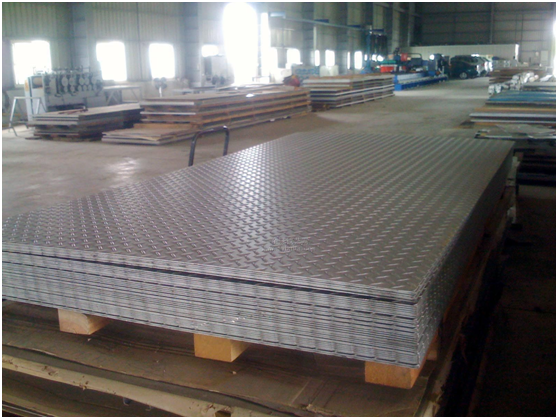

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do you clean stainless steel sheets?

- To clean stainless steel sheets, you can follow a simple and effective process. First, remove any loose dirt or debris from the surface by gently wiping it with a soft cloth or sponge. Next, prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Dip a non-abrasive sponge or cloth into the solution and gently scrub the stainless steel sheet in the direction of the grain. Avoid using abrasive materials or harsh chemicals as they can damage the surface. Rinse the sheet thoroughly with clean water to remove any soap residue. Finally, dry the sheet with a soft cloth or towel, again following the grain to prevent water spots or streaks. This process will help maintain the shine and cleanliness of your stainless steel sheets.

- Q: Why do galvanized and stainless steel sheets buy more expensive than thin ones?

- Effects: galvanized steel sheet is to prevent corrosion of steel plate surface and prolong its service life, and the surface of steel plate is coated with a layer of metal zinc. This kind of zinc coated steel plate is called galvanized sheet.

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Yes, stainless steel sheets are generally resistant to pitting corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface.

- Q: Can stainless steel sheets be used for staircase railings?

- Yes, stainless steel sheets can be used for staircase railings. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor and indoor applications. Additionally, its sleek and modern appearance adds an aesthetic appeal to staircase railings.

- Q: Are stainless steel sheets suitable for medical equipment?

- Indeed, medical equipment can be fabricated using stainless steel sheets. The utilization of stainless steel in medical equipment is widely favored due to its remarkable resistance to corrosion and its ability to endure. It boasts effortless cleaning and sterilization, rendering it fitting for employment in healthcare facilities where cleanliness and hygiene are paramount. Furthermore, the high strength-to-weight ratio of stainless steel permits the creation of lightweight yet robust medical equipment. Moreover, its magnetic permeability is low, rendering it an ideal option for situations necessitating minimal electromagnetic interference. All in all, stainless steel sheets are a dependable and pragmatic selection for the production of medical equipment.

- Q: How are stainless steel sheets measured?

- Stainless steel sheets are measured using various parameters to determine their size, thickness, and dimensions. The most common method of measuring stainless steel sheets is by using gauge thickness. The gauge is a measurement unit used to determine the thickness of the sheet metal. The higher the gauge number, the thinner the sheet. For example, a 16 gauge stainless steel sheet would be thicker and more durable than a 24 gauge sheet. The gauge measurement is often accompanied by the corresponding thickness in inches or millimeters, making it easier to understand the actual dimensions of the sheet. Apart from gauge, stainless steel sheets are also measured by their length and width. These measurements are usually given in feet, inches, or meters. The length and width of the sheet can vary depending on the specific requirements of the project or application. In addition to gauge, length, and width, stainless steel sheets may also have a specific finish or surface texture. These finishes include a variety of options such as brushed, mirror, or textured finishes, which can enhance the appearance and functionality of the stainless steel sheet. In summary, stainless steel sheets are measured using gauge thickness to determine their thickness and durability. The length and width are measured in feet, inches, or meters, and the sheet may have specific finishes or surface textures to meet different requirements.

- Q: Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not as effective as other materials specifically designed for soundproofing, it still has some soundproofing properties. Stainless steel sheets have a high density which helps in reducing sound transmission. Additionally, they have good reflective properties, meaning they can reflect sound waves and prevent them from passing through. However, it is important to note that for effective sound insulation, it is recommended to use materials specifically designed for this purpose, such as acoustic panels or soundproof curtains, as they offer better sound absorption capabilities.

- Q: How do you calculate the bending radius for stainless steel sheets?

- To calculate the bending radius for stainless steel sheets, you need to consider the material's thickness, tensile strength, and the desired level of bendability. The bending radius can be determined using formulas or tables specific to stainless steel, taking into account these factors to ensure the sheet does not crack or deform during bending.

- Q: How do stainless steel sheets compare to other materials?

- Various industries favor stainless steel sheets due to their numerous advantages over other materials. The exceptional durability and strength of stainless steel are well-known. It can endure high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. Moreover, this durability ensures a longer lifespan and reduces the need for frequent replacements, ultimately saving time and money. Stainless steel sheets also possess excellent resistance to corrosion and rust. This property is particularly crucial in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the material's integrity. Unlike aluminum or carbon steel, which may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance, stainless steel sheets naturally possess this quality. Furthermore, stainless steel sheets boast a clean and smooth surface finish, making them visually pleasing and easy to clean. This attribute is of utmost importance in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and minimizes the environmental impact associated with manufacturing processes. In summary, stainless steel sheets surpass other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities establish stainless steel sheets as the superior choice for various industries and applications.

- Q: 304 stainless steel plate 1*1219*C what do you mean?

- 304 stainless steel is a universal stainless steel material, antirust performance than the 200 series of stainless steel material stronger. High temperature resistance is also good, can be as high as 1000-1200 degrees. 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. The oxidizing acid, in the experiments: the concentration of more than 65% of boiling temperature following nitrate, 304 stainless steel has high corrosion resistance. Alkaline solution and most organic acids and inorganic acids also have good corrosion resistance.

Send your message to us

Stainless Steel Plate 309S with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords