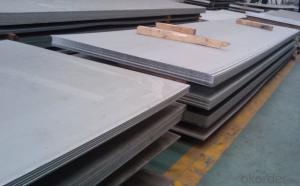

Stainless Steel Sheet 430 with Normal Size #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

How are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are highly resistant to humidity. Their composition, primarily consisting of iron, chromium, and nickel, forms a protective layer that prevents corrosion and rusting even in high humidity environments. This makes stainless steel sheets an excellent choice for applications where moisture resistance is crucial, such as in kitchen and bathroom fixtures, outdoor structures, and marine equipment.

- Q: How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

- Q: Can stainless steel sheets be used for elevator doors or panels?

- Yes, stainless steel sheets can be used for elevator doors or panels. Stainless steel is a common material used in elevator construction due to its durability, strength, and aesthetic appeal. It is resistant to corrosion, which is essential for elevator doors and panels that are exposed to various environmental conditions. Stainless steel sheets can be easily formed and fabricated to meet the specific design requirements of elevator doors and panels. Additionally, stainless steel is easy to clean and maintain, making it a popular choice for high-traffic areas like elevators.

- Q: Can stainless steel sheets be used for elevator panels?

- Yes, stainless steel sheets can be used for elevator panels. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevators. It offers a sleek and modern aesthetic, making it a popular choice for elevator panels in commercial and residential buildings.

- Q: Stainless steel plate more than the thickness of the wire can not be drawn ah?

- It seems more than 8 mm bar, hot rolled on the surface does not look good, 6 mm 304 stainless steel plate, as well as cold rolled, you can wire drawing

- Q: How do I prevent warping on stainless steel sheets?

- In order to avoid warping on stainless steel sheets, there are several actions one can take: 1. Adequate storage: Store stainless steel sheets in a dry, flat, and well-ventilated area. Avoid storing them in areas with high humidity or dampness, as moisture can cause warping. 2. Gentle handling: When moving or handling stainless steel sheets, employ proper lifting techniques to minimize strain on the material. Avoid dropping or mishandling the sheets, as this can result in warping. 3. Precise cutting and shaping: When cutting or shaping stainless steel sheets, utilize appropriate tools and techniques to ensure clean and accurate cuts. Avoid applying excessive force or using incorrect cutting methods, as this can lead to warping. 4. Controlled heat application: During welding or other heat-related processes, it is crucial to control the application of heat. Excessive heat or uneven heating can cause warping. Employ proper techniques, such as preheating the material or using heat sinks, to evenly distribute heat and reduce the risk of warping. 5. Avoid excessive load: Do not overload stainless steel sheets with excessive weight or pressure. Ensure that the load is evenly distributed to prevent deformation and warping. 6. Cooling process: After any heat-related processes, allow the stainless steel sheets to cool down slowly and naturally. Avoid rapid cooling methods, such as water quenching, as this can cause uneven contraction and result in warping. 7. Quality assurance: Ensure that the stainless steel sheets you purchase are of high quality and meet the required standards. Inferior quality materials may possess inherent defects that can cause warping. By adhering to these preventive measures, one can minimize the likelihood of warping on stainless steel sheets and preserve their integrity and quality.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. Stainless steel is a highly durable material that can withstand heavy foot traffic and extreme weather conditions, making it an ideal choice for platforms in railway stations. It is resistant to corrosion, which is crucial in areas exposed to moisture, such as platforms where rain, snow, or spilled liquids may occur. Stainless steel sheets are also easy to clean and maintain, ensuring a hygienic and safe environment for passengers. Additionally, stainless steel has a sleek and modern appearance, adding to the aesthetic appeal of the railway station. Overall, stainless steel sheets provide the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Indeed, manufacturing processes can utilize stainless steel sheets. This highly adaptable and resilient material is frequently employed in diverse industrial sectors. Thanks to its exceptional resistance to corrosion, strength, and ability to endure high temperatures, stainless steel sheets are particularly suitable for manufacturing processes that demand materials capable of withstanding harsh conditions. These include chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive production. Stainless steel sheets can be molded, cut, welded, and machined to meet precise manufacturing specifications, making them a favored option within the industry.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel used, the environment it is exposed to, and the level of maintenance it receives. However, with proper care and maintenance, stainless steel sheets can last for several decades or even longer.

- Q: Can stainless steel sheets be used for decorative signage?

- Indeed, decorative signage can be fashioned from stainless steel sheets. This highly adaptable material presents a sophisticated and contemporary look, rendering it a favored option for diverse purposes, including signage. Its robustness and immunity to corrosion make it fitting for employment both indoors and outdoors. Stainless steel sheets can undergo laser cutting, engraving, or etching to produce elaborate patterns, logos, or lettering, thereby offering boundless potential for decorative signage creation. Whether intended for commercial, residential, or public areas, stainless steel sheets offer an elegant and enduring resolution for decorative signage needs.

Send your message to us

Stainless Steel Sheet 430 with Normal Size #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords