Stainless Steel Plate 430 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

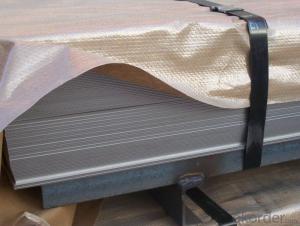

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

What are we supplying now?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a

prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/4

20/430/444/443/409L, and 904L

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Yes, stainless steel sheets are generally resistant to pitting corrosion due to the presence of chromium in their composition, which forms a protective oxide layer on the surface.

- Q: What are the advantages and disadvantages of net drawing stainless steel users?

- The drawing is divided into: stainless steel, oil mill, dry grinding mill, drawing drawing drawing, the drawing effect is the most ideal oil mill, and the appearance is satisfactory!Mirror stainless steel plate making principle is stainless steel plate raw material, with grinding fluid through the polishing equipment in the steel plate surface polishing, make the board surface is smooth and the brightness is as clear as the mirror. Stainless steel mirror panel products are widely used in architectural decoration, elevator decoration, industrial decoration, facilities decoration and other decoration projects.

- Q: What is the typical thickness range for stainless steel sheets?

- The typical thickness range for stainless steel sheets is between 0.4mm and 6mm.

- Q: Inspection method for stainless steel welding

- 1) measurement, in strict accordance with the requirements of the drawings, and to ensure that within tolerance. Along the column, a top cover, and frame, beam should be straight, without distortion, the straightness (nonstraightness) should meet the requirements on the table diagonal method.2) no distortion, swing, rotation or displacement are allowed in the structures which are completely fixed

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent pitting or crevice corrosion on stainless steel sheets: 1. It is crucial to choose the right grade of stainless steel, as grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Ensuring a smooth and clean surface is essential. Corrosion can be initiated by rough surfaces or scratches. Creating a smoother surface can be achieved by polishing or electropolishing the stainless steel sheets. 3. Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Pitting and crevice corrosion are intensified in stagnant environments, so proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Additionally, proper ventilation and humidity control can help reduce the risk of corrosion. 6. Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections should be conducted to detect any signs of corrosion early on. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Are stainless steel sheets suitable for architectural handrails or guardrails?

- Yes, stainless steel sheets are highly suitable for architectural handrails or guardrails. Stainless steel is a popular choice for these applications due to its excellent strength, durability, and corrosion resistance properties. It is able to withstand various weather conditions and is resistant to rust, making it ideal for outdoor installations. Stainless steel sheets can be easily customized and fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, stainless steel has an aesthetic appeal that complements modern architectural designs. It is a low-maintenance material that requires minimal upkeep, making it a cost-effective choice in the long run. Overall, stainless steel sheets are a reliable and versatile option for architectural handrails or guardrails.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- Patterned stainless steel sheets offer several benefits in interior design. Firstly, they add visual interest and uniqueness to a space, allowing for creative and innovative design possibilities. The patterns can range from subtle to bold, providing options to suit various aesthetics and design themes. Additionally, stainless steel is a durable material that is resistant to corrosion, making it ideal for high-traffic areas or spaces prone to moisture. It is also easy to clean, making maintenance hassle-free. The reflective properties of stainless steel can also help to brighten a room and create an illusion of increased space. Furthermore, patterned stainless steel sheets are versatile and can be used in various applications, such as wall coverings, backsplashes, countertops, or even furniture accents. They can be used to enhance both modern and traditional interior designs, adding a touch of sophistication and elegance. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, ease of maintenance, versatility, and ability to enhance the overall visual appeal of a space.

- Q: Are stainless steel sheets suitable for heat exchangers?

- Yes, stainless steel sheets are suitable for heat exchangers. Stainless steel has excellent thermal conductivity, which means it can efficiently transfer heat between fluids. Additionally, stainless steel is highly resistant to corrosion and oxidation, making it ideal for applications where it will come into contact with various fluids or gases at different temperatures. Its durability and ability to withstand high temperatures also make it a reliable choice for heat exchangers. Overall, stainless steel sheets are a popular and reliable material for heat exchangers due to their thermal conductivity, corrosion resistance, and durability.

- Q: What is the process of stainless steel mirror panel? What's the difference between them and stainless steel sand blasting plates?

- The 8K board, also called mirror panel, is polished on the surface of stainless steel by grinding fluid through polishing equipment, so that the surface of the plate is as clear as the mirror. Uses: mainly used in architectural decoration, elevator decoration, industrial decoration, facilities, decoration and other stainless steel products.

- Q: What are the benefits of using perforated stainless steel sheets?

- Using perforated stainless steel sheets in various applications offers several advantages. Firstly, these sheets provide excellent strength and durability due to the high tensile strength and corrosion resistance of stainless steel. This makes them a reliable option for applications that require materials with long-lasting properties. Additionally, the structural integrity of the sheets remains uncompromised even with the presence of perforations, ensuring their ability to withstand heavy loads and harsh environments. Secondly, these sheets offer exceptional ventilation and airflow. The perforations allow air and gases to pass through, making them suitable for applications that necessitate proper ventilation, such as HVAC systems, industrial machinery, and automotive components. This ventilation capability prevents the accumulation of heat and moisture, which is crucial for maintaining the efficiency and safety of various equipment. Furthermore, the design and aesthetic versatility of perforated stainless steel sheets are noteworthy. The ability to customize the size, shape, and pattern of the perforations enables the creation of unique and visually appealing designs. Consequently, they are suitable for architectural applications, interior design elements, and decorative purposes. The wide range of available perforation patterns also allows for the control of light transmission, resulting in interesting lighting effects or privacy screens. Moreover, these sheets possess excellent filtration capabilities. The perforations can be designed to filter out specific particles or substances, making them ideal for applications in the food and beverage industry, pharmaceuticals, and water treatment systems. This ensures the cleanliness and purity of the materials or fluids passing through the sheets, thereby enhancing overall product quality and safety. Lastly, perforated stainless steel sheets are easy to clean and maintain. Stainless steel's non-porous nature makes it resistant to stains, dirt, and bacteria. This, coupled with the presence of perforations, facilitates easy cleaning and disinfection, making them suitable for applications that require high levels of hygiene, such as commercial kitchens, medical facilities, and laboratories. In conclusion, the utilization of perforated stainless steel sheets offers numerous benefits, including strength and durability, ventilation capabilities, design versatility, filtration capabilities, and ease of cleaning and maintenance. These qualities make them a preferred choice in a wide range of industries and applications.

Send your message to us

Stainless Steel Plate 430 with Small Size in #4 Polish Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords