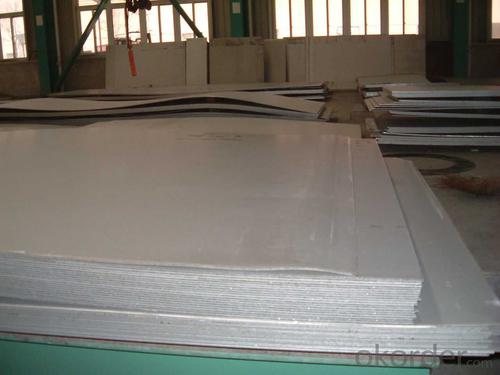

Stainless Steel plate and sheet 202 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for architectural cladding?

- Yes, stainless steel sheets can be used for architectural cladding. Stainless steel is a versatile material that offers a range of benefits for architectural applications. It is highly resistant to corrosion, making it suitable for both interior and exterior cladding in various environments. Stainless steel sheets are also durable and require minimal maintenance, which is advantageous for long-term use in architectural projects. Additionally, stainless steel has an attractive appearance and can be finished in different ways, allowing architects to achieve the desired aesthetic for their designs. Its strength and fire resistance properties further enhance its suitability for architectural cladding. Overall, stainless steel sheets are a popular choice for architectural cladding due to their durability, corrosion resistance, aesthetic appeal, and versatility.

- Q: What are the benefits of using perforated stainless steel sheets in acoustics?

- When it comes to acoustics, there are several advantages to using perforated stainless steel sheets. Firstly, they have excellent sound absorption properties. The evenly distributed perforations in the sheets help to scatter sound waves, reducing their energy and preventing them from bouncing back into the room. This reduces echo and reverberation, creating a more comfortable and clear acoustic environment. In addition, these sheets can be customized to meet specific acoustic requirements. The size, shape, and pattern of the perforations can be adjusted to achieve different levels of sound absorption. This allows for precise control over the acoustics of a space, making it suitable for various applications such as concert halls, recording studios, theaters, or office spaces. Moreover, perforated stainless steel sheets are highly durable and long-lasting. They are resistant to corrosion, making them capable of withstanding harsh environments without deteriorating over time. This makes them suitable for both indoor and outdoor use, ensuring consistent acoustic performance for many years. Furthermore, these sheets offer an aesthetic appeal. The perforations can be designed in different patterns and sizes, providing a visually pleasing and modern look. This makes them a popular choice for architectural and design applications, where both acoustics and aesthetics are important. In conclusion, perforated stainless steel sheets offer excellent sound absorption, customization options, durability, and an attractive appearance. These qualities make them a versatile and effective solution for improving the acoustic performance of various spaces.

- Q: How about stainless steel grades?

- 304 - that is, 18/8 stainless steel. GB is 0Cr18Ni9. 309 - better temperature resistance than 304. 316 - after 304, second of the most widely used steel grades are used mainly in the food, pharmaceutical and pharmaceutical industries, and molybdenum is added to obtain a special corrosion resistant structure. Because of its better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel usually meets this application level. [

- Q: What are the different types of stainless steel sheet coatings available?

- A variety of stainless steel sheet coatings are available, each with its own unique properties and benefits. Some commonly used coatings include: 1. Galvanized Coatings: These coatings protect stainless steel sheets from corrosion and rust by applying a layer of zinc. They are ideal for outdoor applications or environments with moisture or chemicals. 2. Powder Coatings: Offering excellent durability and corrosion resistance, powder coatings are a popular choice. They are applied as a dry powder and heated to form a protective layer. They come in various colors and finishes for customization. 3. Electroplating: This process involves depositing a thin layer of another metal, such as chrome, nickel, or zinc, onto the stainless steel sheet. It enhances appearance and improves resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings are created by depositing a thin film onto the stainless steel sheet using a vacuum process. They offer improved hardness, scratch resistance, and color options, making them suitable for architectural or decorative purposes. 5. Organic Coatings: Paints or lacquers can be applied as organic coatings to provide an extra layer of corrosion protection and aesthetic choices. They are commonly used when color matching or branding is important. Each stainless steel sheet coating has its own advantages and is suitable for specific applications. The choice of coating depends on factors such as intended use, desired appearance, and environmental conditions. It is important to carefully consider these factors and seek expert advice to select the most suitable coating for your needs.

- Q: Are stainless steel sheets suitable for marine applications?

- Yes, stainless steel sheets are highly suitable for marine applications. Stainless steel is known for its excellent corrosion resistance, which makes it ideal for use in marine environments where exposure to saltwater and other harsh elements is common. Stainless steel sheets have a protective oxide layer that prevents rust and corrosion, ensuring their longevity and durability in marine applications. Additionally, stainless steel sheets have high strength and impact resistance, making them capable of withstanding the harsh conditions and stresses encountered in marine environments. Overall, stainless steel sheets are a popular choice for marine applications due to their corrosion resistance, durability, and strength.

- Q: What is the maximum thickness of a stainless steel sheet?

- The maximum thickness of a stainless steel sheet can vary depending on the specific grade or type of stainless steel being used. In general, stainless steel sheets can range from as thin as 0.4 millimeters (0.0157 inches) to as thick as 100 millimeters (3.937 inches) or more. However, it is important to note that the availability of thicker sheets may be limited and can vary based on the supplier or manufacturer. Additionally, some stainless steel alloys may have different thickness limits due to their composition and intended use. Therefore, it is always recommended to consult with a supplier or refer to the specifications provided by the manufacturer to determine the maximum thickness of the specific stainless steel sheet you require.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature stainless steel sheets can withstand depends on the specific grade of stainless steel. Generally, most stainless steel grades can withstand temperatures up to around 1500°F (815°C) before experiencing significant oxidation or scaling. However, certain high-temperature grades of stainless steel, such as 310 or 321, can withstand temperatures up to 2100°F (1150°C) or even higher. It is important to consider the specific application and grade of stainless steel when determining the maximum temperature it can withstand to ensure optimal performance and durability.

- Q: What is the tensile strength of stainless steel sheets?

- The tensile strength of stainless steel sheets can vary depending on the specific grade and thickness of the material. Generally, stainless steel sheets exhibit a higher tensile strength in comparison to other materials. For instance, stainless steel sheets like the commonly used 304 and 316 grades typically possess tensile strengths ranging from 515 to 690 megapascals (MPa) or 74,800 to 100,000 pounds per square inch (psi). However, it is crucial to note that the tensile strength values may differ for various grades and thicknesses of stainless steel sheets. It is always advisable to seek precise information regarding the tensile strength of specific stainless steel sheets from the manufacturer or supplier.

- Q: Are stainless steel sheets good for heat exchangers?

- Yes, stainless steel sheets are excellent for heat exchangers due to their high heat conductivity, corrosion resistance, and durability. They can efficiently transfer heat between fluids and maintain their structural integrity even at high temperatures, making them an ideal choice for various industrial applications.

- Q: Can stainless steel sheets be used for architectural purposes?

- Yes, stainless steel sheets can be used for architectural purposes. This material is highly versatile and offers excellent durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as facades, cladding, roofing, and decorative features. Stainless steel sheets can be shaped, formed, and finished to meet various design requirements, making them suitable for both functional and decorative architectural elements.

Send your message to us

Stainless Steel plate and sheet 202 with plenty stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords