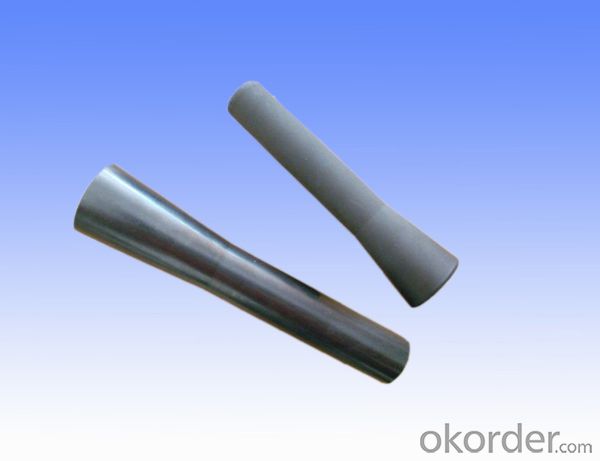

SSIC Axle sleeve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

|

Tailor-made for customers all kinds of pumps with my company, kettle, bearing no pressure sintering silicon carbide mechanical seal, and all kinds of resistance corrosion pump parts and the accessories. Our company pressureless sintered silicon carbide products a reaction bonded silicon carbide products, can easily adapt to the harsh working conditions, in strong corrosive, strong wear, high temperature, high pressure, high strength harsh harsh under complex conditions is more outstanding. At the same time, our company to provide customers with nozzles, armored body armor plate and other special-shaped pieces of custom-made service. Compared with the reaction sintered silicon carbide product (SSIC), the production process of the sintered silicon carbide product (RBSIC) is complex and the production investment is high. In addition, whether it is in the resistance to corrosion and abrasion, compressive and flexural fracture resistance of or high pressure, high temperature and other properties are more excellent, this is pressureless sintering silicon carbide products will in the near future completely replace reaction bonded silicon carbide products is one of the important reasons. The main varieties of the pressureless sintering silicon carbide products with all kinds of mechanical seal with sealing ring and moving ring and static ring, corrosion resistant pump, magnetic pump, shield pump components. At the same time, the production special-shaped pieces of nozzle, wire drawing die, armor plate. According to the drawings, we will provide customers with satisfactory products and customer satisfaction. Let customer satisfaction is one of the purposes of our company has been pursued, but also one of the objectives pursued by all the staff of our company. Features: high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, hardness, heat conduction Main products: mechanical seals, pump parts, nozzles, bullet proof plate Mechanical seals: high hardness, high wear resistance, good self - Lubrication and high heat conductivity, so the service life of mechanical seal is greatly improved. Pump: resistance to corrosion and wear characteristic of the pressureless sintering silicon carbide become magnetic pump sliding bearing, resistant corrosion pump sleeve, shielding pump assembly, etc. various kinds of pump of choice Nozzle: wear resistant, high temperature resistance, high hardness characteristics of the normal pressure sintering silicon carbide nozzle to become a perfect alternative to carbide nozzle Armor: light weight, high hardness, good ballistic performance, pressureless sintering of SiC for your life and property security escort |

Here are some of the pressure sintered silicon carbide products, physical and chemical parameters:

medium | content | Causticity | |||||||

Atmospheric SIC | The reaction SIC WC | WC | AL2O3 | ZrO2 | Si3N4 | stainless steel | steel | ||

HNO3 nitric acid | 50% | A | A | C | A | A | C | C | C |

Hydrochloric acid HCI | 35% | A | A | C | A | A | C | C | A |

Sulfuric acid H2SO4 | 98% | A | A | C | A | A | C | C | A |

Hydrofluoric acid HFF | 40% | A | C | C | C | C | C | C | C |

Phosphoric acid H5PO4 215OC | 85% | C | C | C | C | C | C | C | C |

HNO3+HF | 20%+5% | A | C | C | C | C | C | C | C |

Sodium chlorate NaCIO | 10% | A | B | C | A | A | A | C | A |

Sodium hydroxide NaOHH | 50% | A | C | A | B | A | B | A | A |

Potassium hydroxide KOH | A | C | A | B | A | B | A | A | |

Acetic acid CH3COOHH | 80% | A | A | C | A | A | C | C | C |

Sodium sulfate + Na2CO3 + H2SO4 925OC

| A | A | C | A | A | C | C | B | |

Silica solution SIO2

| B | C | C | C | C | C | |||

Assessment Method: the specimen prior polishing, immersed in the test liquid (70OC) for 100 hours, the weight was measured and observed microstructure, weight reduction is calculated by the degree of corrosion was observed microstructure for corrosion to comprehensive judgments. | |||||||||

A level (corrosion): corrosion rate ≤0.125mm / ingredients in a small amount of corrosion observed slice | |||||||||

Level B (somewhat resistant): corrosion rate = 0.125-1.0mm / or annual corrosion rate ≤0.125mm / observe a large number of corrosion | |||||||||

Class C (resistant to corrosion): corrosion rate ≥1.0mm / or the main ingredient of Corrosion

Silicon carbide performance indicators

Index Name

| Atmospheric SiC | Reaction Bonded Silicon Carbide |

Purity (%) of silicon carbide | > 97 | >90 |

Density (g / cm) | 3.06-3.15 | >3.05 |

Particle size (um) | 0.5-0.7 | 8-20 |

Hardness (HRA) | ≥90 | ≥90 |

Flexural Strength (MPa) | 400-580 | 350-450 |

Compressive strength (MPa) | 3900 | >2500 |

Fracture Strength (MPa) | 3.05-4.6 | 4.3 |

Elastic Modulus (GPa) | 380-410 | 420 |

Thermal conductivity | 102.6 | 35-110 |

Coefficient of thermal expansion (1 / ℃) | 4.02×10 | 4.3×10 |

Poisson's ratio | 0.14 | 0.15 |

- Q: How does the plane move along the Z axis in SketchUp?

- First select the plane, then move it to the blue axis using the moving toolOne, in general, when the moving direction tends to the blue axis, the blue auxiliary line appearsAt this point, the shift can lock the blue axis so that the plane moves along the blue axis

- Q: What is a fire shaft blower?

- 1., according to fan installation methods can be divided into horizontal and roof type.2., according to the pressure classification, there are atmospheric fire, high temperature smoke exhaust fan, medium pressure fire, high temperature smoke exhaust, low pressure fire, high temperature smoke exhaust fan.

- Q: What is the difference between the single and double shafts of an electric motor?Is there a direct linear relationship with torque, centrifugal force, etc.?.Thank you

- There is no direct relation between the shaft length at the two ends, the torque, the centrifugal force, etc. the air curtain machine is made of such motors

- Q: What are the differences between axial and oblique strikes of hydraulic generators?

- . The higher the head drop, the greater the power required to meet the requirements of the pipe. This form can be divided into new and old and new turgo "double double turgo", "four ring pipe spray turgo", according to the change of water source, adjust the number of switching nozzle, make better use of water resources.

- Q: What's the axis control of the mouse?

- The mouse moves ten times distance in the vertical direction to reach the same distance in the horizontal direction on the screen.

- Q: What does DNF's Y axis move and the X axis shift mean?

- Y axis movement refers to the up and down movement, the X axis movement, refers to the left and right movement

- Q: A few days ago, the spindle always stopped, because of the large amount of tasks, but also insisted on using a few days, now replaced with a frequency converter, the problem solved. This afternoon, the Y axis suddenly in the work did not move, but the manual walk a little problem, automatic walking, walk for a while stopped, this is what reason, seek expert answer..

- What's the unusual sound? No manual walking. No problem. Low speed and high speed, okay? And when the Y axis doesn't move, is it still moving in the other directions?

- Q: In the building, the shaft net is drawn up and down, left and right,What is the meaning of "drawing in, left and right" in the drawing of the axle net in the day building? I feel that it is enough to use only the lower opening and the left entry. And there are two axis markers. Should the default be marked with 2 layers?

- Two, when opening and opening are the same size (when the axis number above and below the axis number are the same, no serial number, as long as the) take one can, left and right into the empathy as well.

- Q: Now mechanical keyboard what black axis, red axis, green axis, tea axis, ask God detailed explanationOne by one to talk about what are the characteristics.

- Green axisThis should be regarded as the representative of the MX axis, the characteristics of the pressure is small, strong sense of paragraphs, and there were the voice, if you do not consider the problem of sound, green axis should be the most overall axis, so consider the green axis, the problems needed to be considered only one, is the surrounding environment, if you is intended to purchase in the bedroom, I can guarantee that there will be instant noodles / wonton / Rice with Stewed Pork / pearl milk tea and other unknown liquid down on your keyboard within 3 days, the keyboard sound is a delight for the user, and the surrounding people is suffering.

- Q: Matlab plot () drawing, how to specify the scope of the X Y axis, plot (x, y), can only specify X, Y correspondence, but there is no coordinate axis range and coordinate axis on the designated, how can I do?,I tried axis ([-2,2, -2,2]) and neitherStill not, or will you follow the values of plot (x, y), x, and y to determine the range of the X Y axis, without change?

- Specific: plot () or other command opened in the figure file -- Edit -- Figure Properties -- the following Xlimits entry

Send your message to us

SSIC Axle sleeve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches