Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

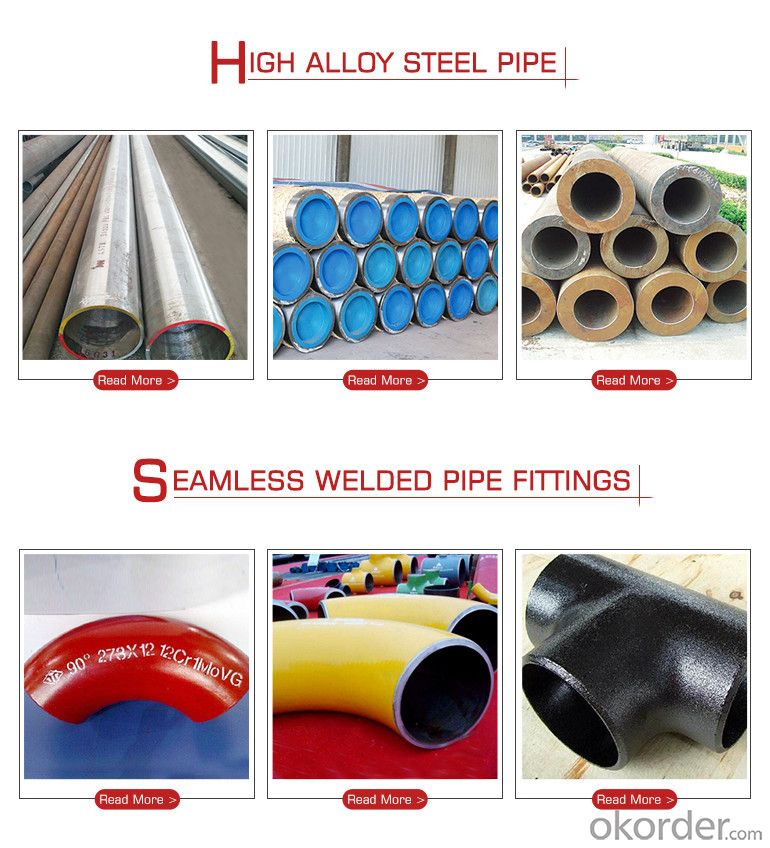

Main materials :10#, 20#, 35#, 45#, 20G, 40Cr, 20Cr, 16mn-45mn, 27SiMn, Cr5Mo, 12CrMo(T12), 12Cr1MoV, 12Cr1MoVG, 10CrMo910, 15CrMo, 35CrMo, 40CrMo, etc.

1. Seamless tubes for construction (GB/ t8162-2008) are seamless tubes for general construction and mechanical construction.

2. Seamless pipe for fluid transportation (GB/ t8163-2008) is a normal seamless pipe for the transportation of water, oil, gas and other fluids.

3. Seamless tube for low and medium pressure boiler (gb3087-2008) is a kind of seamless tube for hot rolling and cold drawing (rolling) of excellent carbon structure steel, which is used for making all kinds of superheated steam tube, boiling water tube, superheated steam tube for locomotive boiler, big pipe, small pipe and arch brick.

4. Seamless tube for high-pressure boiler (gb5310-2008) is a seamless tube of excellent carbon steel, alloy steel and stainless heat-resistant steel for the heating surface of water-tube boiler with high pressure and above pressure.

5. High pressure seamless tubes for fertilizer equipment (gb6479-2000) are excellent carbon structural steel and alloy steel seamless tubes suitable for chemical equipment and pipelines with operating temperature of -40~400℃ and working pressure of 10~30Ma.

6. Seamless tubes for petroleum cracking (gb9948-2006) are seamless tubes for furnace tubes, heat exchangers and pipelines used in petroleum refineries.

7. The steel pipe for geological drilling (yb235-70) is the steel pipe for core drilling in geological part, which can be divided into drill pipe, drill collar, core pipe, casing pipe and deposition pipe, etc.

8. Seamless pipe for diamond core drilling (gb3423-82) is a seamless pipe for drilling drill pipe, core rod and casing for diamond core drilling.

9. The oil drilling pipe (yb528-65) is a seamless pipe with internal or external thickening at both ends for oil drilling.

10. Seamless carbon steel tubes for ships (gb5312-85)

11.Seamless steel tubes (GB/ t18984-2003) for cryogenic piping are used for -45℃ ~ -195℃ cryogenic pressure vessel piping and cryogenic heat exchanger piping

company introduction:

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q: Can steel pipes be used for geothermal energy systems?

- Yes, steel pipes can be used for geothermal energy systems. Steel pipes are commonly used in geothermal installations due to their durability, strength, and resistance to corrosion. They can efficiently transport geothermal fluids, such as hot water or steam, from the geothermal source to the surface for energy extraction or for heating and cooling applications.

- Q: What are the different methods of joining steel pipes for steam applications?

- Some common methods of joining steel pipes for steam applications include welding, threading, and flanging. Welding involves melting and fusing the pipes together, creating a strong and permanent connection. Threading involves cutting grooves into the ends of the pipes and screwing them together using threaded fittings. Flanging involves using a flange to connect the pipes, which is then bolted together for a secure and leak-free connection. Each method has its own advantages and considerations depending on the specific application and requirements.

- Q: How are steel pipes protected against UV radiation?

- Steel pipes are typically protected against UV radiation through the application of specialized coatings or paints that contain UV inhibitors. These coatings form a barrier between the steel surface and the sun's UV rays, preventing degradation, discoloration, and potential structural damage caused by prolonged exposure to UV radiation.

- Q: What is the role of steel pipes in the aerospace industry?

- Steel pipes in the aerospace industry serve various critical roles, primarily in the construction of aircraft structures and engines. They are commonly used for fuel and hydraulic systems, as well as for carrying pressurized air and gases. Steel pipes provide strength, durability, and resistance to high temperatures and pressure, ensuring the safety and reliability of aerospace components. Additionally, they contribute to fuel efficiency by reducing weight and minimizing fuel leakage.

- Q: How do you calculate the stress in a steel pipe?

- To calculate the stress in a steel pipe, you need to determine the applied force or load acting on the pipe and divide it by the cross-sectional area of the pipe. This will give you the stress value, which is typically measured in units of force per unit area (such as pounds per square inch or pascals).

- Q: Can steel pipes be used for conveying potable water?

- Indeed, steel pipes have the capability to convey potable water. Nevertheless, there are certain factors and precautions that necessitate consideration. Steel pipes possess strength and durability, rendering them suitable for the transportation of water across significant distances. They are also resistant to corrosion and capable of enduring high levels of pressure. In order to guarantee the safety and quality of the water being conveyed, it is crucial to employ pipes that have been specifically designed and manufactured for potable water applications. These pipes are often equipped with coatings or linings composed of materials that inhibit the leaching of contaminants into the water, such as epoxy or cement mortar lining. Furthermore, regular maintenance and inspections should be conducted to prevent the accumulation of sediments or rust that could potentially impact the water quality. It is important to acknowledge that steel pipes may prove more costly in comparison to alternative materials such as plastic or copper. Nevertheless, their longevity and reliability render them a cost-effective choice in the long run. Adhering to local regulations and standards concerning the utilization of steel pipes for conveying potable water is also imperative to ensure the well-being and safety of consumers.

- Q: Can steel pipes be painted or coated?

- Yes, steel pipes can be painted or coated. Painting or coating steel pipes helps to protect them from corrosion, rust, and other environmental factors. It also enhances their aesthetic appearance and can be used to indicate the type of pipe or its function.

- Q: How are steel pipes used in the construction of oil-fired power plants?

- Steel pipes are commonly used in the construction of oil-fired power plants for various purposes. They are primarily utilized for the transportation of oil and other fluids within the plant, including fuel oil, lubricants, and cooling water. Steel pipes are also used for the installation of high-pressure steam and water lines, as well as for the construction of exhaust systems, ventilation ducts, and other structural components. Overall, steel pipes play a crucial role in ensuring the efficient and reliable operation of oil-fired power plants.

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, normalizing, quenching, and tempering. Annealing involves heating the steel pipe to a specific temperature and then slowly cooling it to make it softer and more ductile. Normalizing is a similar process but involves air cooling instead of slow cooling. Quenching is a rapid cooling process that results in a hardened and brittle steel pipe. Tempering follows quenching and involves reheating the steel pipe to a lower temperature to reduce the brittleness and improve its toughness.

Send your message to us

Spot 20# seamless steel tube high pressure seamless steel tube Q345B seamless steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords