SPCC Cr Coil/Cold Rolled Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

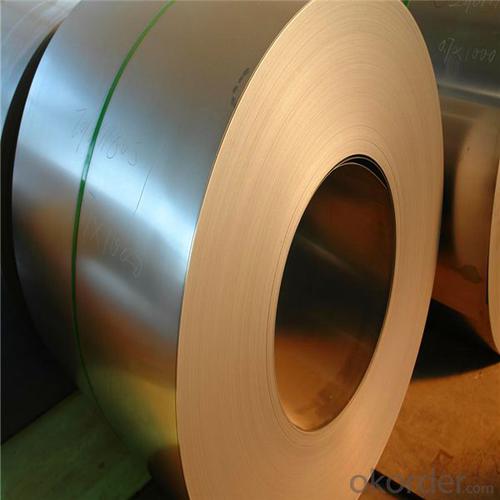

SPCC CR Coil Cold Rolled Steel Coil for building

1.Cold Rolled Steel Coil

1.Thickness:0.18-1.8mm

2.Width:700-1300mm

3.Length:as your need

4.Inner Diameter: 508mm

5.Weight of Steel Coil: 3-15MT

6.Heat Treatment: Annealed

7.Surface Quality: FB&FC

8.Surface Status: SB & SD

9.Surface Treatment: Oiling,unoil,dry,chromate passivated, non-chromate passivated

10.Standard:AISI, ASTM, BS, DIN, GB, JIS

11.Grade;SPCC/SPCD/SPCE/ST12-15/DC01-06.

12.Delivery time:15-20days after receipting the advance payment.

13.Package: Standard export packing or as your requested.

14.Technique: Cold rolled.

15.Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

16.Price terms: FOB CIF CFR

17.Payment : T/T or L/C at sight

18.Samples are available

2.Product Image

3.Packing and Delivery

Delivery time:15-20days after receipting the advance payment.

Package: Standard export packing or as your requested.

Technique:Surface Treatmentunoil,dry,chromate passivated, non-chromate passivated

Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- definitely steel. i used to hit bullseyes with a good slingshot, and you need heavy, perfectly spherical small steel shot. smaller than a marble, bigger than a bb.

- Q: How are steel coils used in the manufacturing of building materials?

- Steel coils are widely used in the manufacturing of building materials due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are shaped into a continuous, flat strip. One of the most common uses of steel coils in building materials is for the production of steel roofing and siding. The coils are processed through a series of machines that cut, shape, and roll the steel into the desired dimensions and profiles. The resulting roofing and siding materials are then used to construct durable and weather-resistant building envelopes. Steel coils are also used in the manufacturing of steel studs, which are essential components for framing structures. The coils are cut and formed into precise shapes, then assembled to create a strong and rigid framework for walls, ceilings, and other structural elements. Steel studs offer numerous advantages such as high strength-to-weight ratio, fire resistance, and dimensional stability, making them a popular choice in the construction industry. In addition to roofing, siding, and framing, steel coils are utilized in the production of various other building materials. These include steel pipes, beams, columns, and reinforcement bars, which are used in the construction of foundations, infrastructure, and structural elements. Steel coils also serve as raw materials for the fabrication of metal panels, doors, windows, and other architectural components. Overall, steel coils play a crucial role in the manufacturing of building materials as they provide the necessary strength and durability required for long-lasting and robust structures. Their versatility allows for the production of a wide range of building components, making steel coils an indispensable resource in the construction industry.

- Q: Aluminum and Steel brittle or ductile based on these results? and why? Steel Aluminium% Elongation 0.2510.2705Modulus of E in ksi11833.33964.71Tensile Strength (ksi)87.5 51.5Yield Strength (ksi)78.5 41

- Only steel(of this pair)might be liable to brittle fracture,which would be implied by almost zero elongation or reduction in area at fracture.On this basis the steel has not failed by brittle fracture.I would expect much more elongation in pure aluminium than your sample shows so I presume it to be brittle unless it is an alloy rather than commercially pure aluminium.However brittle fracture in metals is a particular phenomenon to be determined by impact tests and examination of fracture surfaces and is particularly relevant to metals with the body centred crystal structure.

- Q: Im getting a new guitar soon, and it has steel strings. ive heard that nilon strings are better? thanks:)

- Nylon is allegedly better for beginners because they don't cut into the fingers as much. Steel sounds much better, though.

- Q: How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel is a highly conductive material, allowing for efficient heat transfer. This means that appliances with steel coils, such as refrigerators or air conditioners, can cool or heat up faster, reducing energy consumption. Additionally, steel coils are durable and have excellent heat retention properties, meaning that once the desired temperature is reached, the coils can maintain it for longer periods without consuming additional energy. This helps appliances to operate more efficiently and save on electricity usage.

- Q: What is the average turnaround time for processing steel coils?

- The average turnaround time for processing steel coils varies depending on several factors such as the size, complexity, and specific requirements of the coils. However, it typically ranges from a few days to a couple of weeks.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- If the steel knife is dark and not mirror-shiny, then it is probably carbon steel and not stainless steel. If they are carbon steel, then you cannot polish it to a mirror finish - sorry. If there's any rust on them, you can use a very-fine grit sandpaper to remove. Do not put carbon steel knives in the dishwasher, and dry them thoroughly after hand-washing. For long-term storage (meaning you don't plan to use the knife within the next few weeks), wipe the blade a bit with some mineral oil, then store the blade portion of the knife in a plastic bag.

- Q: What are the different grades of steel used for coils?

- The different grades of steel used for coils vary depending on the intended application and specific requirements. Some common grades include low carbon steel (C1008/1010), medium carbon steel (C1035/1050), high carbon steel (C1074/1095), stainless steel (300 series), and advanced high-strength steel (AHSS) grades such as DP, TRIP, and TWIP. These grades offer varying levels of strength, ductility, corrosion resistance, and formability, allowing manufacturers to choose the most suitable grade for their specific coil processing needs.

- Q: What are the common methods of inspecting steel coils for quality control?

- The common methods of inspecting steel coils for quality control include visual inspection, dimensional measurement, surface inspection, and mechanical testing. Visual inspection involves checking for any visible defects or abnormalities such as cracks, dents, or scratches. Dimensional measurement ensures that the coils meet the specified size and thickness requirements. Surface inspection involves examining the surface finish, cleanliness, and coating integrity. Mechanical testing involves conducting various tests to assess the strength, hardness, and other mechanical properties of the steel coils. These methods collectively ensure that the steel coils meet the required quality standards.

- Q: How are steel coils tested for dimensional accuracy?

- Steel coils are typically tested for dimensional accuracy using various methods such as measuring the width, thickness, and diameter of the coil. This can be done using specialized instruments like calipers, micrometers, and laser scanners to ensure the coil's dimensions meet the required specifications.

Send your message to us

SPCC Cr Coil/Cold Rolled Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords