All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

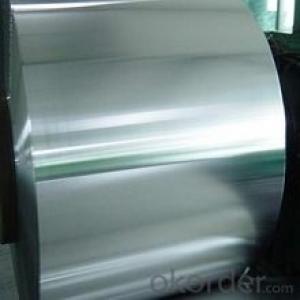

How do stainless steel coils resist corrosion from saltwater?

Stainless steel coils resist corrosion from saltwater due to the presence of chromium in their composition. Chromium forms a thin, protective oxide layer on the surface of the steel, known as a passive film, which acts as a barrier against the corrosive effects of saltwater. This passive film self-heals when damaged, ensuring long-term resistance to corrosion even in harsh saltwater environments.

How is stainless steel coil cut to size?

Stainless steel coil is typically cut to size using specialized machinery such as slitting machines or cut-to-length systems. These machines are capable of accurately cutting the coil into desired lengths or widths, ensuring precise dimensions according to the specific requirements of the project.

What is the lifespan of stainless steel coil?

The lifespan of a stainless steel coil can vary depending on various factors such as the grade of stainless steel used, the environment it is exposed to, and the level of maintenance. However, stainless steel coils are known for their excellent durability and corrosion resistance, which generally allows them to have a long lifespan, often lasting for decades.

Can stainless steel coils be used in wastewater treatment applications?

Yes, stainless steel coils can be used in wastewater treatment applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals present in wastewater treatment processes. It is often used in various components such as heat exchangers, condensers, and piping systems to ensure long-lasting and efficient operation in wastewater treatment plants.

How is a stainless steel coil made?

A stainless steel coil is made through a process called cold rolling. First, stainless steel sheets are fed into a rolling mill where they are compressed between sets of rollers to reduce their thickness. This continuous process is repeated multiple times until the desired thickness is achieved. The rolled stainless steel is then annealed to remove any stresses and improve its ductility. Finally, the stainless steel is coiled or wound into a large spool, ready to be used in various applications such as manufacturing, construction, or automotive industries.

Wholesale Stainless Steel Coil from supplier in Angola

We understand the unique needs of the Angolan market and are committed to delivering high-quality Stainless Steel Coils that meet international standards. Our team of experts is dedicated to providing excellent customer service and technical support throughout the entire procurement process.

With our strong network of suppliers and manufacturers, we are able to offer competitive pricing and timely delivery of Stainless Steel Coils to Angola. Whether you require standard or customized products, we have the expertise to meet your specific requirements.

In addition to our procurement services, we also provide comprehensive after-sales support, including maintenance and repair services for Stainless Steel Coils. Our goal is to ensure that our customers in Angola have a seamless experience from start to finish.

Partnering with us means gaining access to a wide range of high-quality Stainless Steel Coils, competitive pricing, and reliable technical support. Contact us today to discuss your Stainless Steel Coil needs in Angola and let us help you find the best solution for your projects.

With our strong network of suppliers and manufacturers, we are able to offer competitive pricing and timely delivery of Stainless Steel Coils to Angola. Whether you require standard or customized products, we have the expertise to meet your specific requirements.

In addition to our procurement services, we also provide comprehensive after-sales support, including maintenance and repair services for Stainless Steel Coils. Our goal is to ensure that our customers in Angola have a seamless experience from start to finish.

Partnering with us means gaining access to a wide range of high-quality Stainless Steel Coils, competitive pricing, and reliable technical support. Contact us today to discuss your Stainless Steel Coil needs in Angola and let us help you find the best solution for your projects.