Simple Single Side Bracket for Ten Level House Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

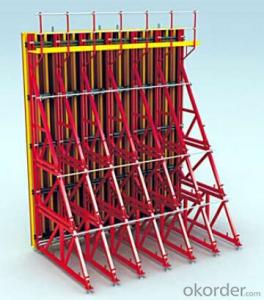

1. Structure of Simple Single Side Bracket

Compared with single-side bracket, it is small in sizes and easy to assemble & dismantlement. So the transportation and piling up is convenient. The maximal pouring height is 3.0m.

2. Main Features of Simple Single Side Bracket

Economical and safe anchoring

Stable and cost-effective for high loads

Simple and flexible planning

3. Simple Single Side Bracket images

4. Simple Single Side Bracket Specifications

The M30/D20 climbing cones have been designed especially for single-sided concreting using .SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still .fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

5. FAQ of Simple Single Side Bracket

1) What can we do for you?

.We can ensure the quality of Simple Single Side Bracket and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: How does a steel prop work?

- During construction and renovation projects, a steel prop, also known as a steel shore or acrow prop, is utilized as a temporary vertical support structure. Its main purpose is to provide temporary support to beams, walls, ceilings, and other structural components. The mechanism behind a steel prop is simple. It comprises of two primary components: an adjustable steel tube and a steel plate. The telescopic steel tube consists of an inner tube that slides into an outer tube, allowing for height adjustment. On the other hand, the steel plate, also referred to as a base plate or footplate, ensures stability and evenly distributes the load onto the ground or supporting surface. To employ a steel prop, the adjustable tube is extended to the desired height and secured in position by tightening a locking mechanism. Then, the steel plate is placed underneath the load-bearing element that requires support. The weight of the structure above is transferred through the steel plate to the ground or supporting surface. The strength and stability of a steel prop are derived from its sturdy construction and the ability to adjust its height. Its telescopic design enables easy customization to match the required height, making it suitable for diverse construction scenarios. Furthermore, the adjustable nature of the prop allows for compensation of uneven surfaces or changes in height during the construction process. Steel props find common applications in supporting walls during demolition, providing temporary support to beams or ceilings during renovation, and stabilizing structures during construction. They play a critical role in upholding the integrity and safety of the surrounding structures by preventing undesired movement or collapse. In conclusion, a steel prop serves the purpose of offering temporary vertical support to structures during construction or repair work. Its telescopic design and adjustable height allow for customization and adaptability to different construction scenarios. The robust construction and load-bearing capacity of the steel prop ensure stability and safety throughout the construction process.

- Q: What are the standard safety regulations for using steel props?

- The standard safety regulations for using steel props include ensuring proper installation and alignment, regular inspection for signs of damage or wear, using appropriate load-bearing capacity props for the specific application, and following manufacturer's guidelines for safe usage. Additionally, it is essential to provide adequate bracing and support to prevent accidental collapse, maintain a clear and safe working area, and train personnel on proper handling and dismantling procedures.

- Q: Can steel props be used for supporting temporary exhibition or trade show structures?

- Supporting temporary exhibition or trade show structures can be achieved using steel props. These props, also known as adjustable steel props or acrow props, are widely utilized in the construction industry to support temporary structures like formwork or scaffolding. They can be adjusted in height and provide sturdy and stable support, making them suitable for various applications. When it comes to supporting temporary exhibition or trade show structures, steel props prove to be an excellent option. They have the capacity to withstand heavy loads and offer reliable support, ensuring the stability and safety of the structure. Additionally, steel props are easy to install and adjust, allowing for quick and efficient setup and dismantling of the exhibition or trade show. Furthermore, steel props can be combined with other construction materials to enhance the overall strength and stability of the temporary structure. For instance, they can be used alongside steel beams or trusses to create a robust framework for supporting exhibition displays, signage, or other elements. It is important to note that the specific design and configuration of the temporary exhibition or trade show structure will determine the quantity and placement of steel props needed. It is crucial to consult with a structural engineer or an experienced professional in temporary structures to ensure proper usage of steel props and adherence to safety standards. Overall, steel props offer a dependable and versatile solution for supporting temporary exhibition or trade show structures. They provide strength, stability, and adjustability, making them an ideal choice for establishing a solid foundation for such structures.

- Q: Can steel props be used for supporting temporary stages and platforms?

- Yes, steel props can be used for supporting temporary stages and platforms. Steel props are adjustable telescopic supports that can be easily extended or shortened to provide the required height and stability. They are commonly used in construction to support formwork, scaffolding, and other temporary structures. Steel props are known for their strength, durability, and load-bearing capacity, making them suitable for supporting heavy loads such as stages and platforms. Additionally, their adjustable nature allows for easy customization to accommodate different heights and configurations. However, it is essential to ensure that the props are properly installed and secured to ensure the safety and stability of the temporary stage or platform.

- Q: How do you ensure proper alignment when using steel props on an inclined surface?

- To ensure proper alignment when using steel props on an inclined surface, it is important to first assess the angle of the incline and ensure that the props are positioned perpendicular to the surface. This can be done by using a spirit level or measuring the angle with a protractor. Additionally, it is essential to securely anchor the props to prevent any movement or shifting. Regular inspections should be conducted to check for any signs of misalignment or instability, and adjustments should be made as needed to maintain proper alignment and stability throughout the use of steel props on an inclined surface.

- Q: What is the average cost of a steel prop?

- The average cost of a steel prop can vary depending on factors such as size, quality, and location. However, generally speaking, the average cost for a standard steel prop can range from $30 to $80.

- Q: Can steel props be used for supporting temporary roof structures?

- Yes, steel props can be used for supporting temporary roof structures. Steel props, also known as adjustable props or acrow props, are commonly used in construction and are designed to provide temporary support to various structures, including roofs. They are made of durable and strong steel materials, which make them suitable for withstanding the weight and load of temporary roof structures. Steel props can be easily adjusted to the required height, providing stability and support to the roof structure. They are typically used in conjunction with other temporary support systems such as scaffolding, beams, and bracing to ensure the safety and integrity of the temporary roof. Furthermore, steel props are versatile and can be used in different construction settings, including residential, commercial, and industrial projects. They are commonly utilized during roofing repairs, renovations, or construction works, where temporary support is needed to ensure the stability of the roof structure. However, it is important to follow proper safety guidelines and consult with a qualified professional or structural engineer to determine the appropriate size, quantity, and placement of steel props for supporting temporary roof structures. This will ensure that the temporary roof is adequately supported and meets all necessary safety standards.

- Q: Are steel props resistant to chemical exposure?

- Yes, steel props are generally resistant to chemical exposure. Steel is known for its high strength and durability, making it less susceptible to damage or corrosion caused by chemical substances. However, the level of resistance may vary depending on the specific type of chemical and its concentration. In certain extreme cases, additional protective coatings or measures may be required to enhance the steel prop's resistance to chemical exposure.

- Q: How do you adjust the height of a steel prop?

- To adjust the height of a steel prop, you typically need to rotate the collar on the prop's outer tube. By turning the collar clockwise, the prop will extend, increasing its height. To reduce the height, turn the collar counterclockwise, causing the prop to retract.

- Q: What is the lifespan of a steel prop?

- The lifespan of a steel prop can vary depending on various factors such as its usage, maintenance, and environmental conditions. Generally, a well-maintained steel prop can last for several years. With regular inspections, repairs, and appropriate storage, a steel prop can be used for multiple construction projects. However, it is important to note that over time, the prop may experience wear and tear, which can affect its load-bearing capacity and structural integrity. Therefore, it is recommended to periodically assess the condition of the steel prop and replace it if necessary to ensure safety and efficiency in construction activities.

Send your message to us

Simple Single Side Bracket for Ten Level House Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches