Painted Metal Steel Scaffolding for Sale(QS)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Model Number: | |||||

| Scaffolding Type: | Usage: | Color: | |||

| Surface Treatment: | Technique: | Material: | |||

| Life Span: | Main Tube Diameter: | Tube thikness: |

Packaging & Delivery

| Packaging Detail: | Steel Scaffolding for Sale: Barely packed in the container or as you required. 23 tons per 20GP container. |

| Delivery Detail: | 20 work days after deposit |

Specifications

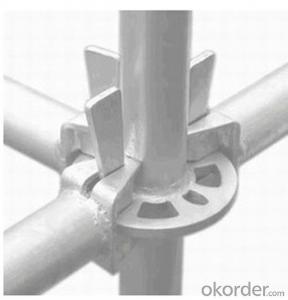

Scaffolding for Sale

1.Painted surface, rust-proof

2.Easy assembly and disassembly, time saving

3.SGS certified

Specifications of Steel Scaffolding for Sale

| Main parts | Mode No. | Quantity | Height/Length |

| Standard | QL001 | 4 | 700/1000/1300/1900/2500mm |

| Ledger | QL001 | 8 | 600/900/1200/1800mm |

| Plate | JP 001 | 8/16 | |

| Blade | LP 001 | 16 |

1. We are manufacturer with more than 14 years experience.

2. We are certified by SGS,BV

3. We have a factory which covers an area of 8000sqm and its daily output is more than 50 tons, so we can assure you the punctual delivery.

- Q: What are the considerations for the use of the axial force gauge to test steel support?

- The axial force of steel support axial force tester, determined before installation must be reserved size, and timely consultation with relevant units to be considered.x0d2 in support of production) in the absence of support to ensure stability measures under the condition of steel support should not use the steel string type axial force meter

- Q: Can steel props be used in temporary support of overhead cranes?

- Yes, steel props can be used in the temporary support of overhead cranes. Steel props are commonly used in construction and industrial applications to provide temporary support for heavy loads, including overhead cranes. Their strength and stability make them suitable for safely supporting the weight of cranes and ensuring a secure working environment.

- Q: Are steel props compatible with different types of scaffolding?

- Yes, steel props are compatible with different types of scaffolding. Steel props are adjustable and versatile support structures that can be used to provide vertical support in various scaffolding systems. They are commonly used to support horizontal beams or platforms, and they can be adjusted to the required height. Steel props are designed to withstand heavy loads and are typically made from high-quality steel, ensuring their compatibility with different types of scaffolding. Whether it is traditional tube and coupler scaffolding, system scaffolding, or frame scaffolding, steel props can be integrated seamlessly to provide the necessary support and stability.

- Q: Can steel props be used in supporting temporary roofs?

- Support for temporary roofs can be provided by steel props, which are also known as adjustable steel props or steel shore props. These props, made from high-grade steel, are commonly used in construction and building projects for temporary support. They offer strong and stable support to structures such as roofs due to their adjustable height. Steel props possess the ability to withstand heavy loads and have excellent load-bearing capacity. They are often utilized to support temporary roofs during construction or renovation work. The adjustable nature of steel props allows for easy setup and adjustment to the desired height, providing flexibility in supporting roofs of varying sizes and shapes. Using steel props to support temporary roofs offers several advantages. Firstly, they are durable and can endure adverse weather conditions, ensuring the safety and stability of the temporary roof. Secondly, they are easy to install and adjust, saving time and effort during the construction process. Moreover, steel props are reusable, making them cost-effective for multiple projects. However, it is crucial to ensure that the steel props used possess appropriate strength and dimensions to support the specific weight and structure of the temporary roof. Seeking the advice of a structural engineer or a construction industry professional is advisable in order to determine the correct size, quantity, and positioning of steel props for supporting temporary roofs. In conclusion, steel props are an effective choice for supporting temporary roofs. Their high load-bearing capacity, adjustability, and durability make them reliable and popular for providing temporary support during construction or renovation projects.

- Q: What are the common maintenance tasks for steel props?

- Common maintenance tasks for steel props include regular cleaning and inspection, lubrication of moving parts, and addressing any signs of damage or wear. Regular cleaning is essential to keep steel props in good condition. This involves removing dirt, dust, and debris from the surface of the props. This can be done using a soft cloth or brush and a mild detergent or cleaning solution. It is important to avoid using abrasive materials or harsh chemicals that can damage the steel. Inspection is another important maintenance task for steel props. This should be done regularly to identify any signs of damage or wear. Inspecting for rust, cracks, or bent parts is crucial to ensure the safety and functionality of the props. If any issues are identified, the props should be repaired or replaced as necessary. Lubrication is necessary for the moving parts of steel props. This includes hinges and joints that may need to be lubricated to ensure smooth operation. Using a suitable lubricant, such as oil or grease, will help prevent friction and maintain the performance of the props. In addition to these tasks, it is important to follow the manufacturer's guidelines for maintenance and care. This may include specific instructions for cleaning, lubrication, and storage. Adhering to these guidelines will help prolong the lifespan of the steel props and ensure their safe and efficient use.

- Q: What are the primary materials used in manufacturing steel props?

- Steel is the main material employed in the production of steel props, as one would expect. To guarantee the props possess the required strength and durability for their intended use, high-quality steel alloys are specifically utilized. These alloys may consist of elements such as carbon, manganese, silicon, and diverse trace elements to attain the desired characteristics. Furthermore, rubber or plastic materials might be employed for specific components or accessories of the steel props, such as grip handles or protective caps. However, the primary composition of the steel props revolves around steel itself.

- Q: Can steel props be used for temporary support during HVAC system installation?

- During the installation of an HVAC system, steel props can serve as a temporary means of support. These adjustable support systems offer temporary stability and load-bearing capacity during construction or installation projects. They are frequently employed to uphold beams, walls, and ceilings, and can be effortlessly adjusted to the preferred height. When it comes to installing an HVAC system, steel props can be utilized to temporarily hold ductwork, air handlers, or other components in place until permanent supports or structural elements are installed. Thanks to their strength and durability, steel props are well-suited for supporting the weight and load of HVAC components during the installation process.

- Q: What are the guidelines for the proper installation and removal of steel props?

- To ensure safety and effectiveness, there are several key steps involved in the proper installation and removal of steel props. Here are the general guidelines you should follow: 1. Before you begin installation, assess the site conditions to ensure they are suitable for steel props. Check for any potential hazards or obstructions that could affect the process. 2. Select the appropriate type and size of steel props based on the load-bearing requirements and the height of the structure being supported. Make sure the props are in good condition and free from any defects or damages. 3. Start the installation by placing the base plate of the steel prop on a stable and level surface. Ensure the prop is vertical and aligned with the load-bearing point. Adjust the inner tube to reach the desired height and secure it by tightening the locking pin or collar. 4. Distribute the load evenly across the prop's base plate. Use timber or steel sole plates if necessary to spread the load over a larger area. This prevents excessive pressure on the ground or floor. 5. Enhance stability by using diagonal bracing or ties between the steel props and the supported structure. This helps prevent lateral movement or collapse in case of unexpected forces. 6. Regularly inspect the steel props during the installation process to identify any signs of instability, bending, or damage. Take immediate action to rectify any issues or seek professional assistance. 7. When removing the steel props, gradually reduce the load on each prop to avoid sudden shifts or collapses. Loosen the locking pin or collar and slowly lower the prop's inner tube in a controlled descent. 8. After removal, inspect the steel props for any damages or wear. Clean them thoroughly and store them in a dry and secure location to prevent rust or deterioration. Regularly maintain and service the steel props to extend their lifespan. Remember to follow the manufacturer guidelines and local regulations specific to your region when installing and removing steel props.

- Q: Can steel props be used in the construction of high-speed rail lines?

- Yes, steel props can be used in the construction of high-speed rail lines. Steel props are commonly used in construction projects to provide temporary support and stability to structures. In the case of high-speed rail lines, steel props can be used to support elevated sections or bridges during the construction phase, ensuring the safety and stability of the infrastructure.

- Q: Steel support can not be removed if the deformation of the foundation pit, how to solve

- Specific analysis of specific issues, but also combined with the value of your pit observation

Send your message to us

Painted Metal Steel Scaffolding for Sale(QS)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords