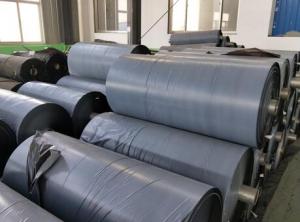

Silicone coated PET release film red,blue,black colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET release film specifications:

| Specifications | |

| Name | Silicone coated PET release film red,blue,black colors |

| Material | Polyethylene Terephthalate (PET) 100% virgin material |

| Thickness | 23um~250um |

| Coating | One or two sides coating/solvent free or solvent |

| length : | makes as orders |

| Colors : | Transparent, white, blue, yellow or as customer’s requirement |

| Testing equipment | testing equipment from USA |

| Sample | |

| Base coating | Silicone oil |

| Application | Adhesive tape/Label and stickers/MLCC purpose/ electrical industrial products |

| Release force | Light mold and heavy mold |

| Feature: | Good-smoothness and evenly plain |

| Usage: | For surface protection during moving, storage, installation etc |

| MOQ: | 10000 square meter |

| Package: | Carton packing with pallets or as customer’s requirement |

| Business type: | with 16 years manufacture experience |

| Our big client : Haier(China's largest home appliance manufacture) ,LG and so on | |

Our silicone release film is used in applications such as:

Release liner for pressure sensitive labels

Release liner for shingle release

Release liner for cast polymer materials

Process liner for adhesive tape manufacturing

Release film in electronic applications

Process liner where a separation is needed during processing or storage

Release liner in the production of ceramic capacitors

Release liner for the window film market

Technical data:

Item | Unit | Measurement method |

| |||||||

SD02 | SD04 | SD06 | SD08 | SD10 | SD12 | |||||

thickness | um | ASTMD374 | 36~250 | 23~250 | 23~250 | 23~250 | 23~250 | 23~250 |

|

|

Haze | % | ASTMD1003 | 2~10 | 2~10 | 2~6 | 8~10 | 2~10 | 2~10 |

|

|

Peel strength | g/inch | TESA 7475 tape(300mm/180 ) | 12~120 | 4~66 | 5~40 | 4~66 | 8~20 | 5~40 |

|

|

Residual adhesiveness rate | % | NITTO 31B tape | >=85 | 85~97 | 97 | 85~97 | >=95 | 97 |

|

|

Surface wetting tension | Dynes |

|

| 19~40 |

|

|

|

| ||

Quality assurance :

Quality has been our major forte. we are committed to meet and exceed our customers’ expectations by providing top-of-the-line products and prompt services. In our endeavors to achieve optimal customer satisfaction, we have developed a total quality management system under the supervision of quality personnel .Our high quality products have earned us a position of repute in the industry.

- Q: What kind of keyboard protection film is good for you?

- The early keyboard protective film was made of TPU material and sold well for a while! Now the keyboard protection film is made of silica gel, TPU, TPU, nano silver. You can choose according to your own needs.

- Q: What are the differences between 360 degrees, 180 degrees and 60 degrees privacy-protective films~

- The differences are: the light transmittance of 360 degrees privacy-protective film (about 60%) is lower than that of 180 degrees film (80%). And 360 degrees film protect privacy in all directions but 180 degrees film in only two directions. 60 degrees refer to the visual angel of the computer user, meaning to look at the screen from an angel of 30 degrees from right or left side to the center line of the screen. Please use 3M authentic privacy-protective products.

- Q: How many kinds of electroplating protective film are there?

- Static film and low-adhesion film used in electroplating factories.

- Q: Is computer screen protective film effective?

- The screen looks so dark that in less than two hours the eyes can't stand it

- Q: What kind of material is acrylic protective film made from?

- Acrylic protective film can be made from PE materials, PET materials and OPP materials, etc. The materials are the materials used in base film of the protective film. And acrylic is a kind of glue.

- Q: What are the materials used in the production of aluminium protective films? What's the harm to life?

- Aluminum protective film is specially formulated with polyethylene (PE) film as substrate, using polyacrylic acid (ester) resin as the main material of the pressure sensitive adhesive, with several specific help glue coated, cutting, packaging and other processes, properties of soft protective film,

- Q: What to do if the adhesion of the PE protective film is too high?

- PE protective film in industry is made of acrylic acid PSA coating (Silica gel is mainly used in PET protective film). The adhesion of protective film is determined by the proportion of original gum and the amount of glue. In the process of application,though, PSA protective film has problem of high adhesion because of the high stickiness of itself.It's directly related to covering and the storage of pressure and temperature. As is known to all, PSA glue is only sensitive to stress. You can adjust the pressure stored when or after the covering. If the protective film itself has high adhesion, you can try to use it when it cool down (Using at temperature below 20℃, you will clearly feel the adhesion comparatively decreased).

- Q: Buy the security door, the window of the protective film, how can you quickly tear down? A long time, have some bad tear

- Stainless steel doors and windows, tables and chairs Aluminum Alloy film a lot, some time was not timely removed, will produce glue phenomenon, how? The following three introduce some simple and effective removal of glue film method.1, with paper towels stained with some alcohol (preferably with industrial alcohol, not to use medical also OK) wipe, and then rub a few times on the clean

Send your message to us

Silicone coated PET release film red,blue,black colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches