Raw Materials for Refractory:Silicon Carbide 90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide90/Recrystallized Silicon Carbide/SIC

1.Structure of Silicon Carbide Description

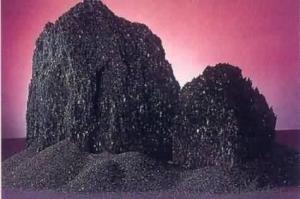

Black Silicon Carbide is produced with high temperature in a electric resistant furnace from a mixture of quartz sand and petroleum coke.

Black silicon carbide is typically used for working on cast iron ,non-ferrous metals, stone, leather, rubber, and other materials which requires sharp cutting characteristics. The mineral is also used widely as a refractory material and metallurgical additive.

2.Main Features of the Calcined Bauxite

Its hardness is between that of fused alumina and synthetic diamond and mechancial intensity of it is also greater than that of fused alumina. It is brittle and very sharp and has a certain degree of electrical and heat conductivity.

3.Main usage of the Calcined Bauxite

1.Grinding non-ferrous materials, rock, stone, leather, rubber, finishing tough and hard materials

2.Bonded abrasive tools, lapping and polishing

3.Widely used as a metallurgical additive and refractory material

4.Refractory

4. Calcined Bauxite Images

5. Calcined Bauxite Specification

Grade | SiC | F.C | Fe2O3 |

≥ | ≤ | ||

SiC98.5 | 98.5 | 0.20 | 0.60 |

SiC98 | 98 | 0.30 | 0.80 |

SiC97 | 97 | 0.30 | 1.00 |

SiC95 | 95 | 0.40 | 1.00 |

SiC90 | 90 | 0.60 | 1.20 |

SiC70 | 70 | 3 | / |

SiC65 | 65 | 5 | / |

SiC60 | 60 | 10 | / |

SiC55 | 55 | 10 | / |

SiC50 | 50 | 10 | / |

6.FAQ of Calcined Bauxite

1). Q: Are you a factory or trading company?

A: We are a factory.

2). Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ningxia, China. You are warmly welcomed to visit us!

3). Q: How can I get some samples?

A: Please contact me for samples

- Q: Can someone professionally introduce the classifications of refractories?

- Whatare the classifications of the refractory index levels? There are three categories of refractory index levels. Anyone familiar with the industry may already know that if you're new to the refractory and don't know much about it, the following information may be helpful to you. Refractory index level can be devided into three general categories of special refractories, advanced refractories and ordinary refractories. The first category, special refractories. Whose refractoriness is higher than 2000 ℃, spinel brick, pure oxide products, high purity directly bonded magnesia-chrome brick, cast products, non-oxide products belong to this grade. The second category, advanced refractories. Whose refractoriness is from 1770 to 2000 Celsius degrees, mullite bricks, high alumina brick, magnesia-alumina brick, ordinary magnesia products, olivine bricks, ordinary magnesia-chrome brick belong to this grade. The third category, ordinary refractories. Whose refractoriness is between 1580 and 1770 Celsius degrees, equivalent to Al2O315% ~ 45% refractory products in the binary system of SiO2-Al2O3. Kaolinite is the main mineral of raw materials.

- Q: Can anyone tell me the requirements of the refractory masonry??

- Kaolin is mainly composed of kaolinite crowded minerals that is in the shpe of tiny flake which is less than two microns, tube and folding flake. The kaolinite crowded mineral consists of kaolinite, dickite, pearl stone, halloysite, etc. and its ideal chemical formula is AL2O3-2SiO2-2H2O. The main mineral component of it is kaolinite and halloysite.In addition to the kaolinite crowded mineral, kaolin is accompanied by other minerals like montmorillonite, illite, pyrophyllite, quartz and feldspar. The chemical composition of kaolin contains large amounts of AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and traces of K2O, Na2O, CaO and MgO, etc. The white pottery is made of kaolin. At present, the internationally accepted scientific name for kaolin is Kaolin which is derived from the kaolin mountain in the eastern suburb of kaolin village in Jingdezhen.Such special properties of kaolin as its plasticity,cohesiveness, certain dry strength, sinterability and firing whiteness make it the main raw material for ceramic production; properties like whiteness, softness, high dispersibility, and adsorbability allows it to be widely used the paper industry. In addition, the kaolin is also widely used in some industrial sectors such as rubber, plastics, refractories, oil refining as well as agriculture sector and cutting-edge technology for national defense. According to the purpose and requirements, kaolin can be processed and purified and it can be used to manufacture activated clay.

- Q: what's the classification of fireproof and thermal inuslation matertial?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

- Q: Fire rating of decoration materials

- You can refer to (code for fire protection design of buildings)

- Q: what kind of fireproof materials is used for high rise buildings?

- First, fire resistance steel door: in the general real estate, developer uses more of fire resistance steel door. The mid-low-end doors are the earliest products and mostly widely used with longer servce time. The disadvantages are corrosions, thus it will rust, fade after being used for a while, and will affect the overall appearance. Styling lines are hard, not matching well with modern home decorative styles. Second, the stainless steel fire doors: anti-theft performance ,durable, stronger security. Compared to the general iron or mixed iron and steel security doors, stainless steel doors never rust and most importantly its uniqueness in addition to lasting bright color. Disadvantages: Stainless steel security doors are mostly silver, giving us dull feelings by seeing its appearance and color, lack of coordination. Third, glass fire door: high quality fire glass doors. recent years have seen wide application in office buildings and some high end public place, less in individual users. Compared to the current categories of timber, fire glass door is not only simple and luxury and durable.

- Q: Who can introduce the external wall thermal insulation materials fire rating regulations?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q: Does anyone know fire-proof material of fireproof wooden door?

- Fireproof wooden door goes through the flame treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method.

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- Could you tell me the fire-resisting time of class B fire proof door?

- Q: What are the grades of refractory exterior wall thermal insulation materials?

- Classification of fire rating of extrior thermal insulation materials 1, According to national standard GB8624-97, the combustion performance of building materials are divided into the following grades A level: Incombustible building materials: Materials hardly burn. B1 class: Flame-retardant building materials: Flame-retardant material has good flame resistance. In case of fire in the air or at high temperature, it is difficult to catch fire and the fire will not spread quickly. And when the combustion source is removed, the burning will stop immediately. B2 Class: Combustible building materials: Combustible materials have a certain flame retardancy. In case of fire in the air or at high temperature, it will immediately burst into flames and it is easily to spread fire, such as wooden column, wooden roof truss, wooden beams and wooden stairs, etc. B3 level: Inflammable building materials: It has no flame retardant effect, and it is extremely inflammable, and the risk of fire is high. Classification of exterior wall thermal insulation materials according to fire rating: 1. Thermal insulation materials with A-level combustion performance Rock wool, glass wool, foam glass, foamed ceramic, foam cement, hole-closed perlite, etc. 2, Thermal insulation materials with B1-level combustion performance: Extruded polystyrene board (XPS) after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polystyrene granule, and etc. 3. Thermal insulation materials with B2-level combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for Refractory:Silicon Carbide 90/Recrystallized Silicon Carbide/SIC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords