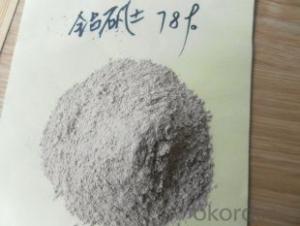

Silicon Bonded Silica Carbon Alloy Ball - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbon ball

At present, the iron and steel metallurgy enterprises usually adopt alloying out of the furnace to adjust the steel composition and use the common recarbonizer to adjust its carbon content. When the molten steel is under peroxy state, since the density of recarbonizer is small, it has poor efficiency of adding carbon. On the other side, it can’t sink into the molten steel and there is little possibility of acting with the molten steel, only can act on the top or on surface, so the recovery rate of carbon is low. Nevertheless, many steel enterprises try to resolve the problem by adding carbon cored wire, which increase the production cost and equipment cost, what’s more, it is much difficult t operate.

We has two production lines, the monthly production capacity is 1000 tons.

Specification

C | Si | S | P | H2O | Granules |

20-30% | 45-55% | ≤0.12% | ≤0.2% | ≤0.5% | 20-50mm |

- Q: what's the varieties of fire-proof?sealing?material?

- ATD-AB, organic fire-proof caulking, fire retardant bag, fire retardant net, fire retardant ring, fire barrier wrap, fireproofing sealing strip, flexibility fireproofing coiled material, fireproof glue, etc., fireproofing sealing materials currently on the market can be divided into two types, one is the traditional type: flexible organic caulking, WXY-II, fire retardant bag, fire?bulkhead, cable refractory coating; there are some new materials used in large-scale projects: fireproofing coating board system (fireproofing coating board, intumescent fireproof sealing tape, elastic fireproof sealant, Waterborne Fire-retardant Coating), fire retardant module system (fire retardant module, sealing gum, cable refractory coating), fireproofing plaster system (fireproofing plaster, sealing gum, cable refractory coating).

- Q: Is there any difference between insulating bricks and refractory bricks? Are there any professional refractories factories that are reliable in the quality and quality of these irritated materials?

- Seven characteristics of insulating brick:Insulation and heat insulation: effectively reduce energy consumption.Fire prevention: up to national standard or class A.Clean and environmental protection: no two pollution will be caused by air.Per square metre weighs only about 1.4 kilograms, reduce the burden of building.Simple production: completely break through the traditional process, greatly shorten the construction cycle.Beautiful: can be modulated into a variety of colors, suitable for Ming outfit.Durable: long service life.

- Q: What kind of refractory materials are used in metallurgy industry?

- Argon-blowing rod, siliceous dry vibrating materials, desulfurizer, slag-stopping ball, stainless steel thermal insulating agent with high efficiency, dry vibration material, sizing nozzle heat-insulating panel, chrome refractory , refractory carstables for ladles, magnesia carbon refractory, package castable, siliceous drainage agent, tundish block, iron trough, deoxidizer, compound deoxidizer,silicon manganese alloy , stemming, floating plug,slagging agent. The main materials are as follows: recarburizer, covering agent, intermediate frequency furnace burden, mould fluxes, insulation thin slag agent, skimmer repair material, joint sealant.

- Q: Who knows what kind of fire prevention materials are there?

- 1, Fire-proof board Fire-proof board is the most frequently used materials in the market. There are two kinds of fireproof boards which are commonly used; one is the high pressure decorative board, which has the advantages of fire prevention, damp proof, abrasion resistance, oil resistance, easy cleaning, and more variety of colors and designs. The other one is a glass magnesium fire board, the outer layer of which is a decorative material, the inner layer of which is a mineral glass magnesium fire material. It can resist 1500-degrees high temperature, but not suit for decoration. The installation of fireproof ceiling in the exit passageway, stair well and corridor can ensure safety evacuation, and protect people from the spread of the fire. 2 Fire-proof door Fireproof door is divided into wooden fire proof door, steel fire proof door and stainless steel fire proof door. Usually the fire proof door is used for the opening of the firewall, the entrance to the staircase, the evacuation of the aisle, the openings of the pipeline and other parts of the building, and it has an important role in fire separation and reducing the loss from fire. 2 Fire resisting shutter I hope it may be helpful to you.

- Q: What is the role of the vermiculite fireproof material?

- Apart from inflaming retarding, the materials covered with vermiculite has a lot of advantages including anti rust, waterproof, anticorrosive, wear-resisting, heat-resisting and the coating is armed with toughness, colorability, adhesiveness, fast-drying and luster.

- Q: How to apply the alumina powder on refractories?

- What kind of the refractories can make the aluminium oxide increase the aluminum content and specific gravity, and erosion-resistant.

- Q: what's the varieties of thermal insulation material with A level fire?rating?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

- Q: What's the frequently used refractory material?

- Refractory material is generally used in industrial departments like metallurgy, glass, cement, ceramics, machinery, hot working, petrochemical industry, power and national defense. Frequently used common refractory: silica?brick, semi-silica brick, clay brick, high alumina brick, magnesia brick, etc. Frequently used special refractory: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, calcium oxide, chromium hemitrioxide, alumina, magnesium oxide, etc. Frequently used fireclay insulating refractory: diatomite product, asbestos product, insulation?board, etc. Frequently used unshaped refractory: ramming refractory, refractory castable, plastic refractory, refractory mortar, gun-mix refractory, refractory coating, lightweight refractory?castables, etc.

- Q: What is the main material of fireproof wooden door?

- Fireproof door is an important part of fire-fighting apparatus and society fire prevention, so the quality and use of fireproof door is the key to the success of the fire prevention. Some customers don't know clearly that whether the fireproof door should install a door closer. Today I specially read the explanation of relevant state departments for fireproof door, in the explanation in 5.3.3, fireproof door should be installed fireproof door closer or set, so that normally open fireproof door can automatically close close-door device of the door leaf (except for the use of special parts, such as pipe shaft doors, etc.) in the event of a fire. In other words, except for some special parts which don't need to be installed door?closer, such as pipe shaft doors, other parts are required to install fireproof door closer.

- Q: Fefractory of aluminium oxide.

- Do you mean the alumina hollow ball brick? We can exchange private messages in specific.

Send your message to us

Silicon Bonded Silica Carbon Alloy Ball - Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords