Silica Brick Silica Carbide Refractory Nozzle & Silica Carbide Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory well block

Item | WB-1 | WB-2 | WB-3 |

Al2O3(%)Min | 55 | 65 | 70 |

C+SiC(%)min | / | 6 | / |

Refractoriness (°C) Min | 1710 | 1790 | 1770 |

Apparent porosity(%)max | 20 | 16 | 15 |

B.D(g/cm³)Min | 2.6 | 2.7 | 2.65 |

Cold crushing strength (Mpa) Min | 30 | 30 | 40 |

Zirconia Refractory nozzle

1.Advantage:high refractoriness, good thermal shock resistance, erosion resistance and

scouring resistance, small hole diameter change, long service life, etc.

2.Usage:

Sizing nozzle is mainly used for continuous casting tundish samll square billet,big square billet,

rectangle billet,small slab casting steel.

3.Related prodcuts:

Zirconia bearing plate,Continuous casting aluminum carbon, aluminum zirconium carbon nozzle,

chock plug,Alumina magnesia, zirconium carbon slide gate,Quick change nozzle,Mosaic nozzle,

Monoblock stopper,long nozzle,submersed nozzle,pocket block,etc.

4.Product data:

zirconium core:

Item | ZN- 65 | ZN- 70 | ZN- 75 | ZN- 80 | ZN- 85 | ZN- 90 | ZN- 93A | ZN- 93B | ZN- 93C | ZN- 93D | ZN- 95A | ZN- 95B | ZN- 96 |

ZrO2(%) | ≥65 | ≥70 | ≥75 | ≥80 | ≥85 | ≥90 | ≥93 | ≥93 | ≥93 | ≥93 | ≥95 | ≥95 | ≥96 |

Bulk density (g/cm3) | ≥3.8 | ≥3.8 | ≥3.9 | ≥4.0 | ≥4.1 | ≥4.3 | ≥5.1 | ≥4.9 | ≥4.7 | ≥4.4 | ≥4.6 | ≥5.2 | ≥5.2 |

Apparent Porosity(%) | ≤23 | ≤22 | ≤22 | ≤20 | ≤20 | ≤20 | ≤13 | ≤15 | ≤18 | ≤20 | ≤20 | ≤9 | ≤5.6 |

Thermal shock resistance (cycles)(1100℃,water cooling) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >8 | >10 |

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

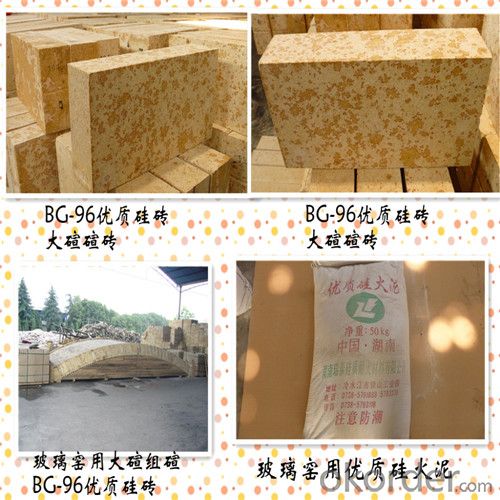

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: The introduction of silica brick

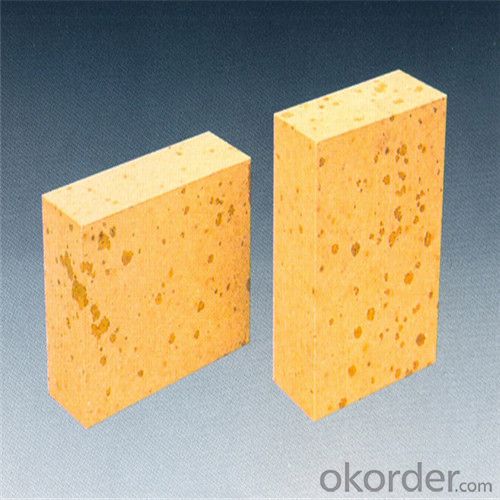

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

Send your message to us

Silica Brick Silica Carbide Refractory Nozzle & Silica Carbide Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords