Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

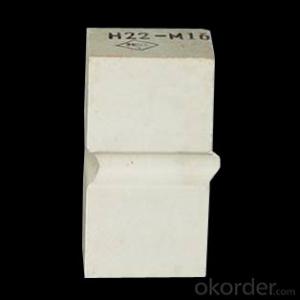

Silicon mortar is adhesive material matched with silica brick. Our silicon mortar has such advantages as high adhesive strength, high refractoriness, excellent refractoriness under load, and good installation performance.

Feature

Control the liquid system, Adhesive, Polymer's rheology and thixotropy.

As additive agent used to prevent subside,thickening and prevent sagging.

Reinforce HRC high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber.

Improve the quality of the powder, and improve the liquidity and anti-blocking characteristic.

Application

paint and coating, Unsaturated polyester resins, laminating resins and gel coat.

HCR high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber. Adhesive and fluid sealant, Printing ink, Cable rubber,Plant protection,Food and cosmetics.

Technical Data

| ITEMS | XR-150 | XR-200 |

Form | White powder | White powder |

Whiteness | 98 | 98 |

SiO2 (dry basis) % | ≥99.9 | ≥99.9 |

PH value | 3.5-4.5 | 3.5-4.5 |

BET surface area m2/g | 150±15 | 200±25 |

Bulk density g/L | 40-50 | 40-50 |

Average particle size nm | 14-15 | 14-15 |

Heating loss (105 for 2hr.) % | 0.5-1.0 | 0.5-1.0 |

Ignition loss (1000 for 2hr.) % | 1.0-2.0 | 1.0-2.0 |

package | 10kg/bag | 10kg/bag |

Photos for Workshop

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Iron scale powder 0.45-0.55%, cement 0.9-1.1%, lime milk 6.5-7.5%, pulp 1.95-2.2%, the silica powder, perlite will be added to the wet mill in proportion, and then add iron scale powder, cement, dry roller 1-2 minutes later

Send your message to us

Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords