Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Composite Panel Facade Decoration Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Composite Panel Facade Decoration

Extremely strong agglutination

Excellent weather resistance

Excellent fire-retardant performance

Light and easy to machining, excellent impact resistance, easy to maintain

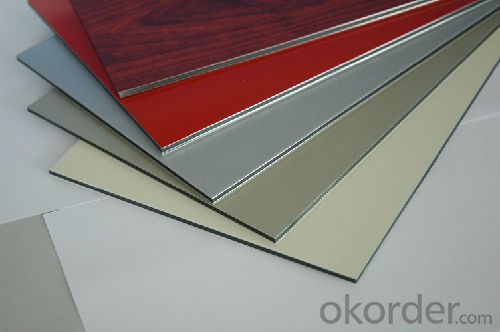

Coating : PVDF, PE, Granite-textured, Wood-textured, Mirror

Color: at your option. ( We could mix the color according to your reqirement.)

Surface and rear aluminum foil can be coating with fresh color as your requirement.

All of Aluminum foil is made from famous aluminum manufacture

In the middle is the no-toxicity Plastic core

PVDF coating can be effected for 15 years, and the PE coating can be effected for 8 years.

Images of Aluminium Composite Panel Facade Decoration

Aluminium Composite Panel Facade Decoration Specification:

| Specification | Recommend | |

| PVDF | 4*0.4mm | Most popular in the world for out door decoration |

| 4*0.5mm | Best for out door decoration in general | |

| 4*0.3mm | Economy also meet requirement for outdoor decoration | |

| 3*0.3mm | Popular for indoor decoration in commercial building | |

| 4*0.5mm Fireproof | Superior fireproof performance on the basis of the best specification | |

| PE | 3*0.3mm | Most popular in the world for indoor decoration |

| 3*0.21mm | Economy for indoor decoration in general | |

| Standard size | 1220*2440 and 1250*2440mm | |

| Accepted width | Max:1580mm | |

| Accepted length | Max:6000mm | |

| Accepted thickness | 2mm,3mm,4mm,5mm,6mm | |

| Aluminum alloy thickness | ACP thick | AL thick |

| 2mm | 0.06mm-0.15mm | |

| 3mm | 0.06mm-0.21mm | |

| 4mm | 0.06mm-0.55mm | |

| 5mm | 0.06mm-0.55mm | |

| Weight | 5kg/m2, based on 4*0.4mm,1400pcs/20'FCL | |

| Nonstandard | Sizes are available according your requirement | |

FAQ of Aluminium Composite Panel Facade Decoration

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: How do aluminum sheets perform in terms of fire resistance?

- Aluminum sheets have excellent fire resistance properties. Due to their high melting point, they can withstand extreme heat and do not contribute to the spread of fire. Additionally, aluminum forms a protective oxide layer when exposed to fire, which further enhances its fire resistance capabilities.

- Q: Can the aluminum sheets be used for manufacturing kitchen countertops?

- Yes, aluminum sheets can be used for manufacturing kitchen countertops.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Yes, 101 aluminum sheets are suitable for outdoor applications.

- Q: Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels. Aluminum is a lightweight yet strong material that offers several advantages for automotive applications. Its high strength-to-weight ratio allows for improved fuel efficiency and better overall performance of the vehicle. Aluminum also has excellent corrosion resistance, making it suitable for withstanding harsh environmental conditions. Additionally, it can be easily formed and manipulated, allowing for complex designs and shapes required for automotive body panels. These characteristics make aluminum sheets a popular choice in the automotive industry for manufacturing body panels.

- Q: Can aluminum sheets be used for elevator panels?

- Indeed, elevator panels can be made using aluminum sheets. Aluminum, renowned for its versatility and durability, finds extensive utility in construction and architectural undertakings, such as crafting elevator interiors. It possesses various merits, including its lightweight nature, resistance to corrosion, and effortless maintenance. Aluminum panels can be tailored to meet the precise design prerequisites of elevator interiors, and their aesthetic appeal and durability can be amplified by applying diverse surface treatments or coatings. Moreover, aluminum emerges as an environmentally-conscious choice for elevator panels due to its sustainability, as it can be readily recycled.

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- No they are not but they are STUPID. Has a story or poem ever had the PING of the bat? No! It's the CRACK of the bat that's what the game is all about.

- Q: What is the cost of aluminum sheets compared to other materials?

- The price of aluminum sheets can vary based on factors such as thickness, size, quality, and market conditions. Nevertheless, when compared to materials like stainless steel or copper, aluminum sheets are generally more cost-effective. This is because aluminum is easily accessible and has a lower production cost, leading to its relatively affordable price. Moreover, aluminum is lightweight, durable, and resistant to corrosion, making it a favored option in many industries. It is important to consider that prices may change due to market demand, raw material availability, and other economic influences.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Sign Aluminum Sheets for Aluminium Composite Panel Facade Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords