Graphite Crucible for Sale Near Me - SIC Crucibles for Melting Aluminium, Copper, and Brass with High Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for SiC Graphite Crucibles

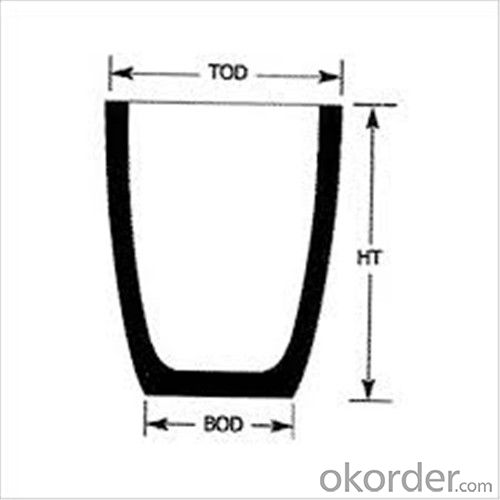

| Type: | High Strength, graphite crucible crucible | Application: | melting metal | Height: | as your requirements |

| Composition: | High Pure | Top Diameter: | 10-600mm | Bottom Diameter: | 10-1000mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ||

| Color: | Black grey | Si3N4%: | 5min | Fe2O3%: | 0.7max |

| C%: | 30-45 | Apparent porosity: | 30max | Refractoriness: | 1680 |

| Bulk Density: | 1.71min | Using life: | >5000 hours | MAX temperature: | 1600c |

Packaging & Delivery

| Packaging Details: | Seaworty packing or as per customer's detail requirement of graphite crucible. |

| Delivery Detail: | within 20-30 days after confirm order of graphite cru |

SiC Graphite Crucibles For Melting Aluminium And Copper, Brass

Product Description

Specifications for Graphite Silicon Carbide Crucible For Aluminum Melting :

1.Long working lifetime: its working lifetime is increased 3-5 times over normal clay-crucible due to the compact body formed under high pressure.

2.High thermal conductivity: high-density body and low apparent porosity greatly improve its heat conductivity.

3.New-style materials: new heat conduction material ensures faster heat conductivity and pollution-free product, reduces adherent slag.

4.Resistance to corrosion:better anti-corrosion than normal clay-crucible.

5.Resistance to oxidation: advanced process dramatically improves its oxidation resistance, which ensures persistent heat conductivity and long working lifetime.

6.High-strength: high-density body and logical structure make the product better compression property.

7.Eco-friendly: energy-efficient and pollution-free, not only ensure metal product purity, but also ensure sustainable development on environment.

8.Multi-function: Can be used in induction graphite crucible furnace

Features of SiC 95% silicon carbide sic crucible

1. resistance to deformation at high temperature,

2. thermal shock resistance, wear resistance, corrosion resistance.

3. anti-oxidation, anti- erosion.

Usage of SiC 95% silicon carbide sic crucible

electricity and steel slag trench,

coal chemical and mining transport pipeline.

- Q: Can graphite crucibles be used for carbon nanotube synthesis?

- Graphite crucibles are capable of being utilized in the synthesis of carbon nanotubes. Due to its high melting point and chemical stability at elevated temperatures, graphite serves as a suitable material for this purpose. In the process of synthesizing carbon nanotubes, a carbon source is commonly subjected to intense heat, and graphite crucibles have the ability to endure such extreme conditions without undergoing reactions or contaminating the nanotubes. Moreover, graphite crucibles possess efficient thermal conductivity, which aids in maintaining a consistent temperature throughout the synthesis procedure. Consequently, graphite crucibles are extensively employed in laboratories and industries for the fabrication of carbon nanotubes.

- Q: Are there any health risks associated with using a graphite crucible?

- Using a graphite crucible can pose certain health risks. Graphite crucibles are commonly utilized in high-temperature applications like metal casting, melting, and chemical reactions. However, when exposed to high temperatures or during handling, graphite itself can emit small particles or fine dust. Inhaling graphite particles can potentially lead to respiratory problems, particularly for individuals with pre-existing respiratory conditions like asthma or chronic bronchitis. Prolonged exposure to graphite dust can also result in the development of a lung disease known as graphite pneumoconiosis. Moreover, graphite crucibles have the ability to absorb and release trace amounts of impurities, such as heavy metals or other toxic substances, which can contaminate the materials being processed. This poses a risk to both the workers handling the crucibles and the final products. To minimize these health risks, it is crucial to handle graphite crucibles with caution and utilize appropriate personal protective equipment like gloves and masks. Maintaining a well-ventilated workspace and regularly cleaning the crucibles are also important to reduce the release of graphite particles. It is advisable to regularly monitor and evaluate the air quality in the working environment to ensure the safety of the workers.

- Q: How does the wall thickness of a graphite crucible affect the melting process?

- The melting process is significantly influenced by the thickness of the graphite crucible walls. The walls' thickness determines both the crucible's heat transfer rate and overall efficiency. If the wall is thicker, it possesses greater thermal mass, enabling it to absorb and retain more heat. This proves advantageous in applications where a gradual and controlled heating or cooling process is desired. The increased thermal mass aids in stabilizing the temperature, preventing rapid fluctuations that can negatively impact the melting process. Alternatively, a thinner wall possesses less thermal mass and facilitates faster heat transfer. This proves beneficial when quick and efficient melting is required. The thinner walls allow for swifter heat transfer to the material being melted, resulting in shorter melting times and increased productivity. However, it is crucial to note that a thinner wall may be more susceptible to thermal stress and cracking due to the greater temperature differentials between the inner and outer parts of the crucible. This can potentially contaminate the melted material or even cause the crucible to fail. Moreover, the wall thickness affects the crucible's overall durability and lifespan. Thicker walls generally exhibit greater resistance to wear and tear, providing a longer operational life. This becomes particularly important in high-temperature applications where the crucible is exposed to extreme conditions. To summarize, the wall thickness of a graphite crucible directly impacts the melting process. Thicker walls provide improved temperature stability but may result in longer melting times, while thinner walls allow for faster heat transfer but may be more susceptible to thermal stress. Selecting the appropriate wall thickness depends on the specific requirements of the melting process and should be carefully considered to achieve optimal results.

- Q: Can a graphite crucible be used for melting thorium?

- Indeed, a graphite crucible proves quite useful when it comes to melting thorium. These crucibles find extensive application in scenarios involving high temperatures, such as the melting of metals and alloys. Notably, thorium exhibits a relatively low melting point of 1,750 degrees Celsius, a temperature comfortably within the range that graphite crucibles can endure. The exceptional thermal conductivity and ability to withstand high temperatures are attributes well-associated with graphite crucibles, rendering them ideal for the melting and manipulation of diverse metals and alloys, including thorium.

- Q: Can graphite crucibles be used for material synthesis?

- Yes, graphite crucibles can be used for material synthesis. Graphite has excellent thermal conductivity, chemical resistance, and high temperature resistance, making it suitable for various material synthesis processes such as melting, calcination, and fusion. Additionally, graphite crucibles can withstand rapid temperature changes and are inert, making them ideal for use in the synthesis of different materials.

- Q: How to calculate the loss of aluminum slag melting?

- Look at the size of aluminum slag, big saw recovery rate is high, small saw fine chip is low.

- Q: Why does the graphite crucible used for molten gold add a quartz coat?

- The melting point of gold is 1063 degrees Celsius. At this temperature, graphite reacts with oxygen in the air to produce carbon dioxide. The quartz coat may be used to prevent leakage of graphite crucibles

- Q: I'd like to smelt 104 aluminium alloy by medium frequency furnace. What should I pay attention to? Please point it out, thank you!

- If the intermediate frequency furnace may smelt, pays attention to the coating, will cross several furnaces to have to paint once.The alloy after melting also needs to be transferred to the heat preservation furnace, and then the slag removal and degassing are carried out. Because of the rotation of the aluminum liquid in the intermediate frequency furnace, the separation effect of slag inclusion is very poor.

- Q: Medium frequency furnace plus graphite crucible does not start

- The graphite content of the crucible is too low, the furnace is not tight enough, the quartz sand is not tight between the induction ring and the crucible, and can not start or the electric current is slightly large, and the power is automatically cut off.

- Q: Can graphite crucibles be used for melting organic materials?

- Yes, graphite crucibles can be used for melting organic materials. Graphite is known for its high melting point and excellent thermal conductivity, making it a suitable material for high-temperature applications. When melting organic materials, such as polymers or organic compounds, it is important to use a crucible that can withstand the high temperatures without reacting or contaminating the material. Graphite is chemically inert and does not react with most organic substances, making it an ideal choice for melting organic materials. Additionally, graphite crucibles are typically designed to have good thermal shock resistance, allowing them to withstand rapid temperature changes during the melting process. Overall, graphite crucibles are commonly used in various industries, including chemistry and metallurgy, for melting organic materials due to their excellent heat resistance and chemical inertness.

Send your message to us

Graphite Crucible for Sale Near Me - SIC Crucibles for Melting Aluminium, Copper, and Brass with High Heat Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords