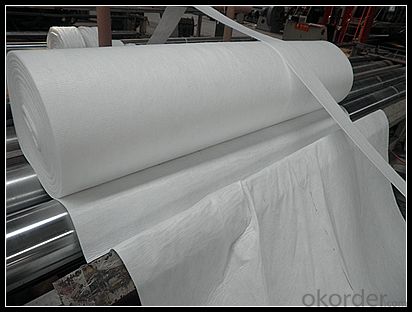

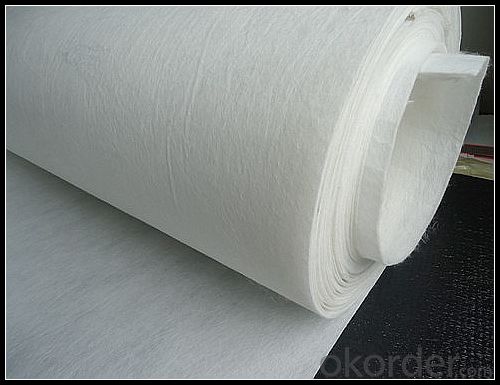

FHWA Certified Short Non-Woven Geotextile Road Building Constructive Felt Fabric with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM Geotextile acts as a separator between two layers of soil that have different particle size distributions. CNBM Geotextiles are used to prevent road base materials from penetrating into soft underlying sub grade soils, thus maintaining design thickness and roadway integrity. Separators also help to prevent fine-grained sub grade soils from being pumped into permeable granular road bases.

Filtration

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils from migrating into drainage aggregate or pipes while maintaining flow through the system. CNBM Geotextiles are also used below rip rap and other armour materials in coastal and river bank protection systems to prevent soil erosion.

filtration

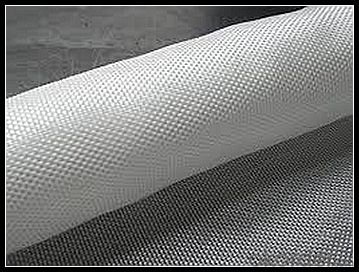

Reinforcement

CNBM Geotextile acts as a reinforcement element within a soil mass or in combination with the soil to produce a composite that has improved strength and deformation properties over the unreinforced soil. CNBM Geotextiles are used to add tensile strength to a soil mass in order to create vertical or near vertical reinforced soil walls and steep slopes.

Reinforcement

Separate: Geotextile when used as a separation layer prevents two different fill materials such as aggregate and soil from combining. When used correctly the geotextile will increase the life span of the civil project, allowing the two separate layers to perform as designed for longer.

Protection: Geotextile when used as a protection layer acts as a cushioning barrier between the geosynthetic lining system and other layers of the dam or landfill cell. Generally the larger mass rolls of geotextile provide the best cushioning protection. As a protection barrier it helps prevent puncturing and leaks from external forces coming into contact with the liner.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- Geotextiles generally do not design applications in tunnel waterproofing. Because he can not meet the requirements of tunnel waterproofing

- Q: What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects typically include factors such as the tensile strength, puncture resistance, elongation properties, and durability of the material. The geotextile should also have the ability to separate and stabilize the soil layers, provide filtration to prevent soil fines from clogging drainage systems, and possess adequate permeability to allow for efficient water drainage. Additionally, geotextiles used in railway projects must meet certain standards for dimensional stability and resistance to environmental factors such as UV radiation and chemical degradation.

- Q: Do you have a drainage board and geotextile on the roof

- Good, but you use very little, the purchase is difficult, the price will not be cheap Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in subsurface drainage applications?

- Yes, geotextiles can be used in subsurface drainage applications. Geotextiles are often used as a filter or separator in drainage systems to prevent soil erosion and clogging of drainage pipes. They allow water to pass through while retaining soil particles, thus enhancing the performance and longevity of subsurface drainage systems.

- Q: How do geotextiles help with asphalt overlay?

- Geotextiles help with asphalt overlay by providing reinforcement and stabilization to the underlying soil, preventing it from shifting or settling. This helps to increase the longevity and durability of the asphalt overlay, as well as reducing the occurrence of cracks and potholes.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can enhance soil nutrient availability by promoting better water and air circulation, preventing soil erosion, and increasing organic matter content. This allows for improved nutrient uptake by plants and reduces nutrient leaching, ultimately leading to healthier and more fertile soils.

- Q: How do geotextiles improve drainage systems?

- Geotextiles improve drainage systems by acting as a filter and separator. They prevent soil particles from clogging the drainage system while allowing water to pass through freely, thereby enhancing the overall drainage efficiency.

- Q: How do geotextiles aid in the reduction of lateral spreading?

- Geotextiles aid in the reduction of lateral spreading by providing reinforcement and stability to soil structures. These textiles are designed to have high tensile strength and are placed horizontally within the soil to act as a barrier against the lateral movement of soil particles. This helps to distribute stress and prevent the soil from shifting laterally, thereby reducing the potential for slope failure or landslides.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These factors include the type and strength of the soil, the slope angle, the water conditions, the expected load and stress on the slope, the desired vegetation cover, and the available space for construction. Additionally, the design should account for the potential for erosion and the need for drainage to prevent water buildup. The selection of appropriate geotextile materials and installation techniques is also crucial for ensuring long-term stability and effectiveness of the reinforced slope.

- Q: How do geotextiles enhance drainage systems?

- Geotextiles enhance drainage systems by providing a filtration layer that allows water to pass through while preventing soil particles from clogging the system. They also improve the overall stability and longevity of the drainage system by preventing soil erosion and maintaining the integrity of the soil structure.

Send your message to us

FHWA Certified Short Non-Woven Geotextile Road Building Constructive Felt Fabric with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords