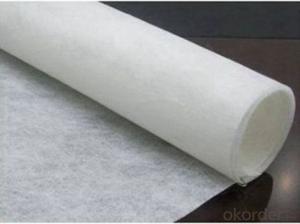

Gs-1 High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

Product introduction:

1.high quality geotextiles

2.CE, ISO9001, ISO14001

3 Sample available

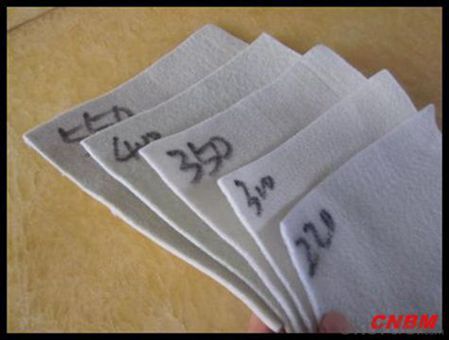

4. 100-800g/m2

Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile Commission test how many square meters

- Hello, geotextile cloth sent to the third party testing, the general sampling is one to two squares, on the site supervision sampling sampling, it may also cut a large piece, see the supervision of the Huazhi engineering materials manufacturers for you to answer

- Q: How do geotextiles help with waste containment systems?

- Geotextiles play a crucial role in waste containment systems by providing a barrier that prevents the leakage of contaminants into the surrounding environment. They act as a protective layer, enhancing the stability and integrity of waste containment structures such as landfills or waste ponds. Geotextiles help to control erosion, reinforce the containment system, and provide filtration for leachate, thus minimizing the risk of pollution and ensuring a safer and more sustainable waste management solution.

- Q: How can the geotextile extension of 65 to do the following

- I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a filtration and separation layer between the soil and the retaining structure in green walls. They help retain moisture, prevent soil erosion, and provide stability to the system.

- Q: What are the specifications for geotextiles in civil engineering projects?

- The specifications for geotextiles in civil engineering projects typically include factors such as the material type, weight, strength, permeability, and durability. These specifications ensure that the geotextile selected is suitable for the intended application, whether it's erosion control, filtration, separation, or reinforcement. Additionally, the specifications may also cover aspects like installation requirements, testing methods, and compliance with industry standards to ensure the geotextile performs effectively and meets the project's requirements.

- Q: Basically I'm thinking of doing a thesis defense on this topic and I want to know if it is any good.

- Any bio-degradable material is not a better substitute for a geotextile material in long run Materials from polymer family may suit better, like Polyamide Polypropylene Polyethylene My answer refers to about having the ability to separate, filter, reinforce, protect, or drain If your purpose of using geotextile material regarding Beach Erosion, Riverbank Erosion, then coconut fibers is a better option

- Q: Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles provide effective erosion control, drainage, and filtration properties, making them suitable for lining canals to prevent soil erosion and improve water flow.

- Q: What is the length of the lap when the two-way geogrid is used? What is the geotextile lap length?

- It should be 20cm to 40cm it, geotextiles slightly longer point

- Q: What are the key factors affecting the tensile strength of geotextiles?

- The key factors affecting the tensile strength of geotextiles include the type and quality of the material used, the manufacturing process, the thickness and weight of the geotextile, the orientation of the fibers, and the presence of any additives or coatings. Additionally, the installation and maintenance conditions, such as soil characteristics, temperature, moisture levels, and load distribution, can also impact the tensile strength of geotextiles.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These include the type and strength of geotextile to be used, the slope angle and height, soil properties, expected loads and stresses, water drainage and erosion control measures, construction methods, and long-term performance requirements. Additionally, site-specific conditions such as climate, vegetation, and nearby structures should also be taken into account. Proper consideration of these factors ensures a safe and stable design that effectively mitigates slope failures and erosion.

Send your message to us

Gs-1 High Quality Non Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords