Sheets of Aluminum Diamond Plate with Better Discount Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

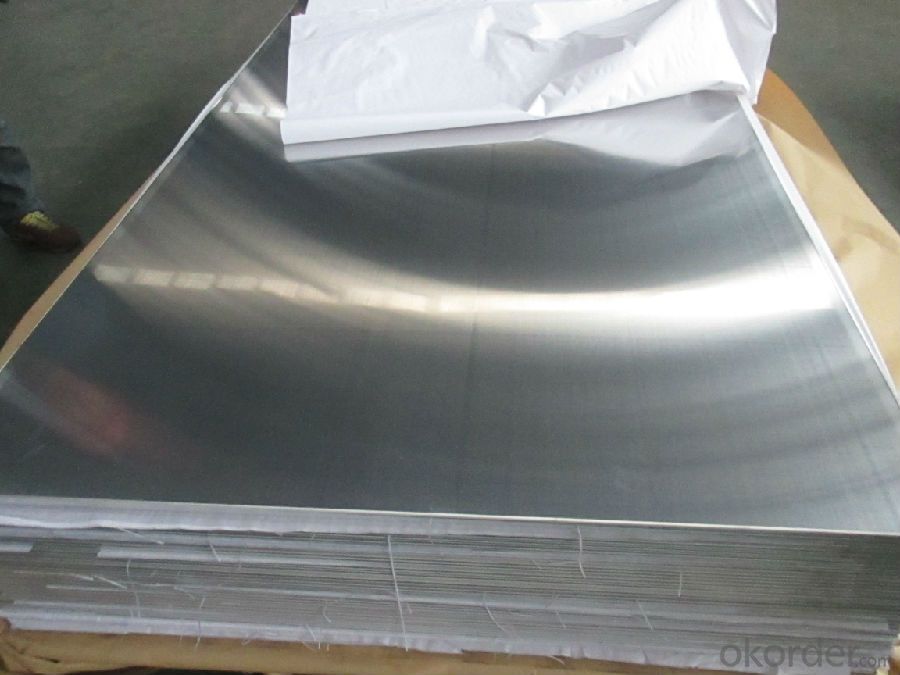

1.Structure of Product Description

Cold rolled aluminum sheet and hot rolled sheet are all widely used in the field of construction field and decoration field, etc. we have different sizes also, There are many different grades, such as: 1000 series, 2000 series, 7000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010,1100, 1060,1050, 2024, 3003, 3005, 3105, 5052,7075, 6063,8011, etc.

The temper is include H14,H44,O, F, H112,H114,etc.

2. Main features of the product

a. Competitive price

b.Frist-Class Service.

c. Shortest service.

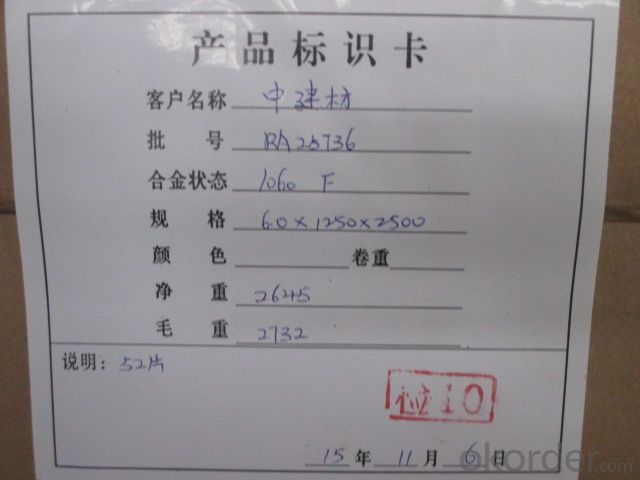

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 500*500,600*600, 700*700, 800*800,900*900, etc.

1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally they are cold rolled and hot rolled and checkered sheet, and mirror finished sheet, etc.

aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is lightweight yet sturdy, providing excellent protection for electronic components. It is also corrosion-resistant, making it suitable for various environments. Additionally, aluminum is a good conductor of heat, allowing for effective thermal management in electronic enclosures.

- Q: How do aluminum plates paint?

- Pretreatment is usually required. Acid and alkali cleaning can be done either by oil or by xylene,The paintings do not know, but most of them are painted or printed on the aluminum plate, usually by heat transfer, silk screen, or decorative board, which is sprayed directly and then painted.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Indeed, furniture manufacturing can make effective use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers a multitude of advantages for the production of furniture. It possesses corrosion resistance, rendering it suitable for both indoor and outdoor furniture. Moreover, aluminum showcases a remarkable strength-to-weight ratio, facilitating the creation of robust and long-lasting furniture items. Additionally, aluminum proves to be easily malleable, as it can be cut, bent, and welded into various shapes and designs. Furthermore, aluminum can be treated with a diverse range of coatings or paints to enhance its visual appeal and safeguard it from damage. In summary, the strength, versatility, and aesthetic allure of aluminum sheets establish them as a viable alternative for furniture manufacturing.

- Q: What are the different types of finishes available for aluminum sheets?

- There are several types of finishes available for aluminum sheets, including mill finish, anodized finish, painted finish, brushed finish, and embossed finish.

- Q: Are the aluminum sheets suitable for manufacturing solar panel backings?

- Aluminum sheets, indeed, prove to be a fitting choice for the production of solar panel backings. With its exceptional properties, aluminum has gained significant popularity in the solar industry. Its lightweight nature, durability, and resistance to corrosion make it highly suitable for outdoor applications. Furthermore, aluminum exhibits a remarkable ability to conduct heat effectively, a critical factor for ensuring the efficient operation of solar panels. Moreover, the recyclability of aluminum makes it an environmentally conscious option for solar panel manufacturing. All in all, aluminum sheets serve as an appropriate material for the fabrication of solar panel backings.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: What are the different types of surface treatments available for marine-grade aluminum sheets?

- There is a variety of surface treatments available for marine-grade aluminum sheets, each with unique benefits and characteristics suitable for different applications. 1. Anodizing: By electrolysis, a protective oxide layer is created on the aluminum sheet's surface. Anodized aluminum sheets provide excellent resistance to corrosion, increased durability, and can be colored or dyed for aesthetic enhancement. 2. Powder Coating: Dry powder is applied to the aluminum sheet and then cured through heat, resulting in a tough and durable coating. Powder-coated aluminum sheets offer exceptional resistance to corrosion, abrasion, and fading, and come in a wide range of colors. 3. Polishing: Imperfections on the aluminum sheet's surface are removed through polishing, resulting in a smooth and shiny finish. This treatment is commonly used for decorative purposes to enhance the visual appeal of marine-grade aluminum sheets. 4. Brushing: Abrasive pads or brushes are used to create a textured surface on the aluminum sheet. Brushing is often employed to conceal scratches or imperfections and can provide a unique aesthetic appearance. 5. Chemical Conversion Coating: A chemical solution is applied to the aluminum sheet, reacting with the surface to form a protective coating. Chemical conversion coatings enhance the aluminum's corrosion resistance and can also serve as a base for further surface treatments, such as painting. 6. Clear Coating: A transparent protective layer is applied to the aluminum sheet. Clear coating helps prevent corrosion and oxidation while maintaining the natural appearance of the aluminum surface. When selecting a surface treatment, it is crucial to consider the specific requirements and intended use of the marine-grade aluminum sheets. Each treatment offers different characteristics in terms of corrosion resistance, durability, aesthetics, and cost, allowing for customization based on the application's specific needs.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures due to their low density and high strength-to-weight ratio.

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

Send your message to us

Sheets of Aluminum Diamond Plate with Better Discount Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords