Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Semi-transparent Static Film to Protect Electronical Parts

Metal in static shielding film made our of VMPET/PE films for packaging ESD sensitive devices.It is uesed for making ESD static shielding bags ,Thoes films are available with or without printing

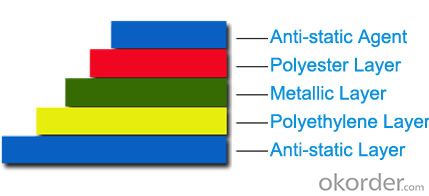

Film construction:

Anti-static Static Shielding Film echnical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | ANSI/ESD STM 11.11 | |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | <100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | ||

| Material Thickness | 3.6mil+/-10% | ** |

| Puncture Resistance | ≥10.0lbs | MIL-PRF-81705D |

| Tensile Strength | > 4500 psi MD/TD | ASTM D882 |

| Seam Strength | No separation | MIL-PRF-81705D |

| Optical Density | Opaque(Sliver) | ASTM D-882 |

| Heating sealing Conditions | 375°F 0.5sec.60 PSI | ** |

| MVTR | < 0.02grams/100sq. in/day | ASTM F-1249 |

| Appearance | No tears,holes,sctratches,etc. | |

| Chemical Properties | .Compliant to ROHS,REACH, | |

| Halogen free ETC requirement | ||

| Amines/Amides | Not detected | FTIR |

Antistatic Static Shield Film Roll Film specifications:

Width:450-1300mm

Thickness:0.07-0.17mm

Printing: Standard with ESD requirements,approx 50X50mm

Yellow. Date code(YYMM).

About us :

Btree is China's top 5 supplier of Static Shielding Bags and Moisture Barrier Protection. We offer a full range of

ESD Packaging solutions. Speak to our friendly team or request a brochure.

ESD Moisture Barrier Film Technical Data

| Electrical Properties | Typical Values | Test Method |

| Surface Resistance | | ANSI/ESD STM 11.11 |

| Interior | <10E11ohms | |

| Exterio | <10E11 ohms | |

| Metal | 100 ohms | |

| Static Shielding | <15 nJ | ANSI/ ESD STM11.31 |

| Static Decay | <0.03 seconds | EIA 541 |

| Charge Generation | < 100 volts | ** 15kV and 12% RH |

| Physical Properties | | |

| | | |

| Material Thickness: | 4.0mils+/-10% | |

| Puncture Strength | 10.0 lbs | MIL-PRF-81705D |

| Seam Strength | No separation | MIL -PRF-81705D |

| Heating sealing Conditions | | |

| Temperature | 300°F -400 °F | |

| Time | 0.6 -4.5seconds | |

| Pressure | 30 – 70 psi | ASTM D882 |

| Tensile Strength | >3,500 psi MD/TD | ASTM F-1249 |

| Water vaporTransmission (@100°F&90%RH) | <0.006grams/100 sq in/day | |

| | | |

| Visual inspection | No tears,holes,sctratches,etc. |

Produce progress:

Packaging

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be eye-catching. This can only be used as a horizontal contrast. In the same environment, the most striking one is the one that can be distinguished from other products at one glance. Also take the moon cake as an example, the Mid Autumn Festival, the general moon cake gift box is red, golden yellow based, above is not the moon, is the flower, most of them are like this. If the design is blue, the package is also shown in the same area. Must be the most striking.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: What are the packaging forms of fresh milk?

- Pasteurized milk as milk sterilization, the glass bottle packaging plastic bags or plastic bottles, plastic bags are simple, like using the monolayer polypropylene material, because these materials are difficult to achieve in aseptic filling and sterilization of milk filling environment, generally do not take aseptic production, such products require cold chain transportation, and shelf life short, usually within 3 days, but the fresh sense of strong, low packaging cost, cheap price. In addition, pasteurized milk is also available in roof type cartons and glass bottles.

- Q: Printing process of packaging bag

- If there is no peritoneal, press the printer faster;

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is low density polyethylene, and PE-LD should be low density polyethylene. Because according to the PE classification, LDPE (low density polyethylene), MDPE (medium density polyethylene), HDPE (high density polyethylene), VLDPE (low density polyethylene), LLDPE (linear low density polyethylene (mPE), metallocene PE). See, "LD" means "low density".

- Q: Is there any identification on the vacuum package?

- Continue ink jet printer (continuous spraying machine), referred to as CIJ inkjet printer. The principle of operation is that the ink is ejected continuously through a single nozzle and is broken by crystal oscillation to form ink dots. After the ink point is charged and deflected at high pressure, the ink is scanned on the surface of the moving object. Such as Domino A100.

- Q: Why is the higher the elevation, the more food bags inflate? From a physical point of view

- The higher the altitude, the less the atmosphere, the smaller the pressure, and the pressure in the food package is a fixed value. The reason for the swelling of food packaging bags is that the pressure inside the food bags is greater than the external pressure!

- Q: Should the food packaging bags be labeled with QS markers?

- Hello, you me to answer the question: is not needed, packaging bag manufacturers is the right to own QS logo printing to the packaging bag on your package, the most is according to your request will be posted to the QS carton outside (i.e. certificate below). Your bag can only be printed with your QS logo, or not printed.

- Q: What is the difference between package material PETAL and VMPET?

- What is the difference between PETAL and VMPET performance?:PETAL material with high barrier, sealing, incense retention, shielding and other functionsVMPET material has higher decoration.

- Q: What's bread packing? Polyethylene film, waterproof cellophane, etc.

- The utility model has the advantages that can be repeatedly used, easy to get a longer shelf life of bread to marry, and don't need strapping, can take the heat sealing with metal or plastic coated Sizha live bag, bag packaging has knot with polypropylene plastic bags of bread.

Send your message to us

Semi-transparent Static Film to Protect Electronical Parts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords