Jual Self Adhesive HDPE Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of self adhesive hdpe geomembrane sheet:

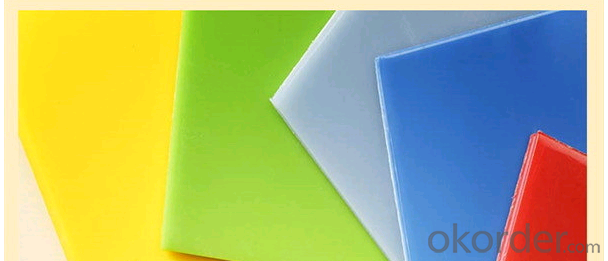

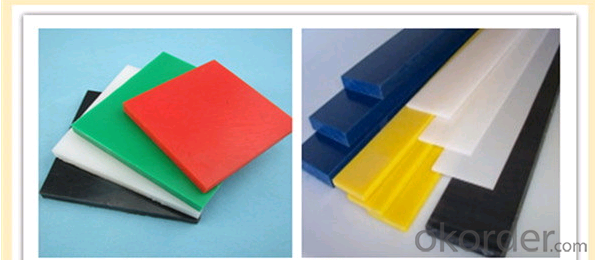

HDPE is a non polar thermoplastic plastic with high crystallinity and perfect electrical properties,especially the high insulation dielectric strengh.This polymer is non-hygroscopic which can be used to packing with good waterproof steam.HDPE with Middle to high molecure weight have good impact resistance at normal temperature even in the zero 40 degree Celisius.

Its surface won't wrinkle and is weather resistant.Because it is durable it has a long service life and acts as a flexible hinge that won't break.Our HDPE sheets can be customes produce to match specific colors,thickness,size and finish.

Advantages of self adhesive hdpe geomembrane sheet:

high insulation dielectric strength

perfect impact resistance

good heat /cold endurance

no toxic

excellent chemical resistance

low water absorption

good temperature properties

great chemical stability

Parameter of HDPE

| density(g/cm3) | 0.91-0.95 | Brittle Temperature(°c) | <-120< span=""> |

| water absorption(%) | <0.01< span=""> | Linear expanding coefficient | 1213 |

| in-process shrinkage(%) | 1.55.5- | Thermal conductivity(W/(m.k)) | 0.44 |

| tensile strength(Mpa) | 21-37 | Volume resistivity(Ω.cm) | 61015 |

| breaking extension(%) | >880 | Dielectric constant(106HZ) | 2.34-2.35 |

| Bending strength(Mpa) | 11 | Dielectric dissipation factor | 0.0003 |

| compressive strength(Mpa) | 10 | Dieletcric strength/(Kv/mm) | >20 |

| impact strength(KJ/m²) | 4070 | Arc resistant/s | 115 |

| Rockwell Hardness | R70 | Oxygen index(%) | 20 |

| Heat formation temperature(°c) | 75 |

Packing and Delivery

| Packaging Details: | self adhesive hdpe geomembrane sheet packing: By pallets or according to your request |

| Delivery Detail: | 10-15days after your deposite |

Why Choose US

1 More than 10 years professional manufacturing experiences with own factory

2 Perfect quality with 100% virgin material

3 Any color and size can be provided with your request

4Competitive price,fast delivery,excellent service

FAQ

1Why use HDPE sheet?

HDPE Sheet has an almost waxy feel to it and is pretty good at being a low friction wear strip material and is used probably more than any other plastic as a wear strip on conveyors or production lines of huge companies.

2When can I get the HDPE price?

After getting your inquiry,the reply will be send to you in 8 hours at most.If you are urgent to get the price,pls call us or tell us in the email so that we will regard your inquiry priority.

3.How long can I expect to get the sample?

After learning all the requirments of the sample clearly,those itmes will be send to you via express which will take 3-5working days.You can use your own express account or prepay us if you do not have an account.

- Q: Can geomembranes be used in industrial wastewater treatment?

- Yes, geomembranes can be used in industrial wastewater treatment. They are often employed as liners in containment systems to prevent the leakage of contaminants from the wastewater into the surrounding environment. Geomembranes act as a barrier that restricts the migration of pollutants, ensuring that the treated wastewater remains contained and does not pose a risk to the environment or human health. Additionally, the use of geomembranes can enhance the efficiency and effectiveness of wastewater treatment processes by facilitating proper waste isolation and management.

- Q: How do geomembranes contribute to the prevention of soil erosion in land reclamation projects?

- Geomembranes contribute to the prevention of soil erosion in land reclamation projects by acting as a protective barrier between the soil and external factors such as water, wind, and sunlight. These impermeable membranes effectively prevent water infiltration and runoff, reducing the risk of soil erosion caused by rainfall or water flow. Additionally, geomembranes can also prevent the loss of nutrients and contaminants from the soil, further preserving its quality and stability.

- Q: Are geomembranes resistant to chemicals?

- Yes, geomembranes are generally resistant to chemicals. They are designed to provide a barrier against chemical substances and are often used in industries where chemical containment is required, such as waste management, mining, and chemical processing plants.

- Q: where can i buy cheap geomembrane?

- Currently. Currently, good frost resistance performance,plastic film applied for seepage-proof at home and abroad, two films a cloth is in favor of the stability of protective layer and composite geo-membrane; vinyl copolymer (EVA). Corrosion resistance; and non-woven staple fiber is macromolecule staple fibre chemical material, mainly including polyvinyl chloride (PVC), polyethylene (PE), it's produced by the manufacturer according to individual requirements, low temperature resistance, various product specifications, there are many domestic geomembrane production manufacturers, ethylene & # 47 through needle stick or hot sticking forming, which is flexible material polymer chemistry, and because the rough non-woven surface, two cloth one film. Meanwhile, the base, etc., has high tensile strength and elongation, smaller proportion, strong extension, not afraid of acid, high?adaptability?to the?deformation, it can be also requested by the user according to their actual situation, and it can not only increase plastic film tensile strength and puncture resistance. The main mechanism is cutting off earth leakage passage with the imperviousness of plastic film, they have good corrosion resistance for bacteria and chemical function and has good chemical resistance, its tensile strength and elongation can withstand water pressure and adapt to dam deformation ; after it is combined with plastic film, increasing the friction coefficient of the contact surface; m2, etc., salt erosion, a cloth membrane, two cloth membrane and two cloth more and more film. Models include 200g & # 47 geomembrane takes plastic film as seepage-proof substrate, its seepage-proof performance depends on seepage-proof properties of plastic film and soil engineering impermeable material composed by non-woven cloth.

- Q: Are geomembranes suitable for use in water containment?

- Yes, geomembranes are suitable for use in water containment. They are impermeable liners made of synthetic materials that can effectively prevent the seepage of water, making them ideal for applications such as reservoirs, ponds, and landfills where water containment is necessary.

- Q: What are the advantages of using geomembranes in oil and gas containment?

- There are several advantages of using geomembranes in oil and gas containment. Firstly, geomembranes provide an impermeable barrier that prevents leaks and spills, ensuring the integrity of the containment system. This helps to protect the environment by minimizing the risk of soil and groundwater contamination. Secondly, geomembranes are highly durable and resistant to harsh conditions, such as extreme temperatures and chemical exposure. This makes them ideal for oil and gas containment where there can be a high level of corrosive substances involved. Additionally, geomembranes are flexible and can be easily installed and customized to fit various shapes and sizes of containment areas, including pits, ponds, and tanks. This flexibility allows for efficient and cost-effective construction and maintenance of containment systems. Lastly, geomembranes have a long lifespan, reducing the need for frequent replacements and minimizing overall maintenance costs. They also require minimal maintenance, making them a reliable and cost-effective solution for oil and gas containment.

- Q: The applied range of HDPE geomembrane

- Refuse landfills, sewage disposal plants, power plant tail slag processing, chemical plants, fertilizer plants, sugar mills sewage and tailings treatment, non-ferrous metallurgy, sulfuric acid tank, tailings disposal, subways, basements, tunnels, roof lining and other special circumstances impermeable (special); reservoirs, canals, dams, laying horizontal impervious, impermeable vertical laying; seawater, freshwater, farms seepage.

- Q: Can geomembranes be used in oil and gas storage applications?

- Yes, geomembranes can be used in oil and gas storage applications. Geomembranes are impermeable liners that are commonly used to contain and protect various types of liquids, including oil and gas. They are designed to provide a reliable barrier against leaks and contamination, making them suitable for storage tanks, secondary containment systems, and other oil and gas storage facilities.

- Q: How to stick the front of the mobile phone film?

- First, use the wet tissue to wipe the mobile phone, and then use the non-woven fabrics or glasses cloth to clean up (preferably in the light). After clean up, tear off the screen film, and align at the hole position, begin to paste from the side, and then slowly paste from the top to the bottom and gently press it to avoid the bubbles.

Send your message to us

Jual Self Adhesive HDPE Geomembrane Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords