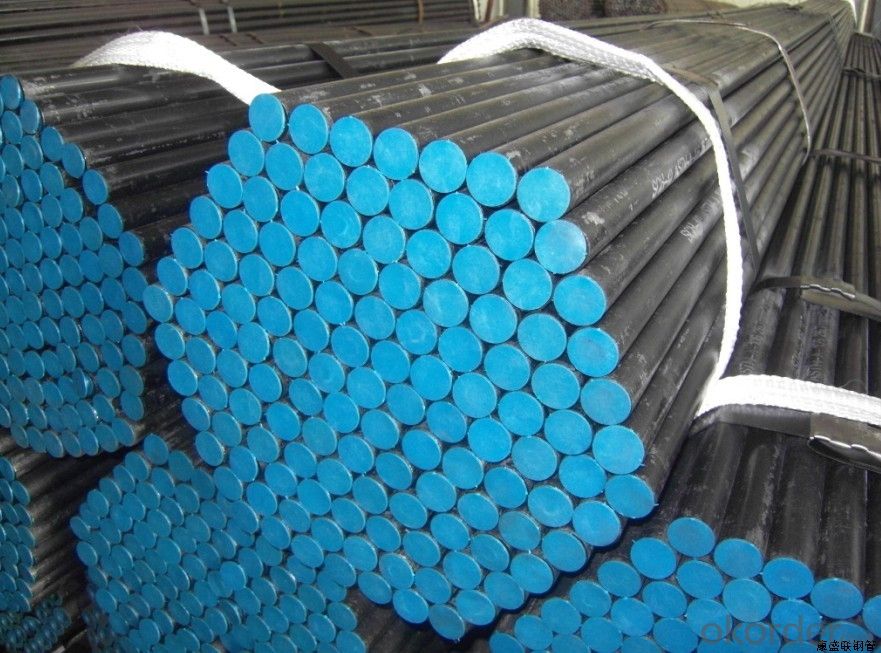

Seamless Boiler Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Descriptions :Seamless Boiler Tube

1.O.D:13.7mm~610mm

2.W.T:2.34mm~30mm

3.Length:5-11.8m

4.Certificate:API 5L,BV

Description | Size | Typical Steel Grade | Standards | Typical Applications | |

OD(mm) | WT(mm) | ||||

Medium and low pressure boiler tube and pipe | 14~720 | 2.0~120 | 10 | GB 3087 | Wall tube, header, steam pipe formedium and low pressure boiler tube and pipe |

20 | |||||

High pressure boiler tube and pipe | 14~720 | 2.0~120 | 20G, 25MnG, 15MoG 12CrMoG, 15CrMoG 12Cr2MoG, 12Cr1MoVG | GB 5310 | Wall tube,header, Steam pipe under the working pressure ≥9.8MPa, Temperature 450~650℃ |

SA106A/B/C | ASME SA106 | ||||

SA179 | ASME SA179 | ||||

SA192 | ASME SA192 | ||||

T1/T1a | ASME SA209 | ||||

SA210A1/C | ASME SA210 | ||||

T2/P2, T5/P5, T9/P9, T11/P11 , T12/P12, T22/P22, T91/P91 | ASME SA213 ASME SA335 | ||||

P195/235/265GH, 16Mo3 13CrMo4-5, 10CrMo9-10 15NiCuMoNb5-6-4 | EN 10216 | ||||

St35.8、St45.8, 15Mo3, 13CrMo44, 10CrMo910 | DIN 17175 | ||||

STPG370, STPG 410 | JIS G 3454 | ||||

STPT370, STPT 410 | JIS G 3456 | ||||

STBA12, STBA22, | JIS G 3462 | ||||

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: What is the impact toughness of steel pipes?

- The impact toughness of steel pipes refers to the ability of the material to withstand sudden or high-velocity impacts without fracturing or breaking. It is a measure of the material's resistance to cracking under dynamic loading conditions. The impact toughness of steel pipes is an important property as it determines their ability to withstand accidental impacts or external forces during transportation, installation, and operation. The impact toughness of steel pipes is typically evaluated using standardized tests such as the Charpy V-notch test or the Izod test. These tests involve striking a notched sample of the steel pipe with a pendulum or a falling weight and measuring the energy absorbed by the material before it fractures. The impact toughness is then calculated based on this energy absorption. A high impact toughness is desirable in steel pipes as it indicates a greater ability to absorb energy and resist fracture, making them more resistant to sudden impacts or loading conditions. This is particularly important in applications where steel pipes are used in high-stress environments, such as in oil and gas pipelines, automotive components, or structural applications. Various factors can affect the impact toughness of steel pipes, including the chemical composition, heat treatment, and microstructure of the steel. For example, alloying elements like manganese, chromium, and nickel can enhance the impact toughness by promoting the formation of fine-grained microstructures and preventing the propagation of cracks. Similarly, proper heat treatment processes such as quenching and tempering can improve the impact toughness by optimizing the material's microstructure and mechanical properties. In summary, the impact toughness of steel pipes is a crucial property that determines their ability to withstand sudden or high-velocity impacts. It is evaluated through standardized tests and is influenced by factors like chemical composition, heat treatment, and microstructure. A high impact toughness is desirable in steel pipes to ensure their structural integrity and resistance to fracture under dynamic loading conditions.

- Q: Can steel pipes be used for plumbing?

- Yes, steel pipes can be used for plumbing. They are commonly used in commercial and industrial applications due to their durability and strength. However, they are less common in residential plumbing due to their higher cost and the availability of alternative materials such as copper and PVC.

- Q: How do steel pipes perform in extreme temperature variations?

- Steel pipes perform well in extreme temperature variations due to their high thermal conductivity and low thermal expansion coefficient. This allows them to efficiently transfer heat and withstand the expansion and contraction caused by temperature fluctuations without compromising their structural integrity.

- Q: Are steel pipes suitable for use in hydropower plants?

- Yes, steel pipes are suitable for use in hydropower plants. Steel pipes offer several advantages such as high strength, durability, and corrosion resistance, making them ideal for transporting water or fluids in hydropower plants. Additionally, steel pipes can withstand high pressure and temperature conditions, ensuring smooth and efficient operation of the hydropower plant.

- Q: How are steel pipes used in the construction of railways and transportation systems?

- Steel pipes are used in the construction of railways and transportation systems primarily for their durability and strength. They are utilized for various purposes such as the fabrication of tracks, bridges, tunnels, and support structures. Steel pipes provide a reliable and long-lasting solution for the transportation industry, ensuring the safety and efficiency of railway systems.

- Q: What are the specifications for steel pipes used in high-pressure applications?

- The specifications for steel pipes used in high-pressure applications typically include factors such as material composition, wall thickness, diameter, and pressure rating. These pipes are often made from strong and durable steel alloys, such as carbon steel or stainless steel, to ensure their ability to withstand high pressures. The wall thickness and diameter of the pipe are carefully selected to handle the specific pressure requirements of the application. Additionally, the pipes may need to meet certain industry standards, such as ASTM or ASME codes, to ensure their quality and performance in high-pressure environments.

- Q: How are steel pipes used in the manufacturing of machinery and equipment?

- The manufacturing of machinery and equipment heavily relies on the widespread utilization of steel pipes, thanks to their numerous advantageous properties. These pipes serve as a primary means of conveying different materials, fluids, and gases within the machinery, effectively ensuring safe and efficient transportation. One crucial application of steel pipes in machinery manufacturing lies in the realm of hydraulic and pneumatic systems. Hydraulic systems depend on steel pipes to transmit power and regulate fluid flow, while pneumatic systems utilize these pipes to transport compressed air, powering various components. The strength and durability inherent in steel pipes guarantee their ability to withstand the immense pressure and forces exerted by these systems, making them a dependable choice for such purposes. Moreover, steel pipes find extensive use in the construction of machinery frames and structures. Their exceptional tensile strength and resistance to corrosion make them an ideal option for providing structural support and stability to heavy machinery. These pipes can be effortlessly welded, bent, and fabricated into diverse shapes, allowing for flexibility in design and enabling the creation of intricate machinery structures. Furthermore, steel pipes play an indispensable role in the transportation of raw materials and finished products throughout the manufacturing process. They frequently serve as conduits for the movement of liquids, gases, and granular materials, ensuring the smooth operation of machinery and equipment. Steel pipes are particularly well-suited for handling abrasive and corrosive materials, as their robust construction guarantees minimal wear and tear over time. In conclusion, the extensive utilization of steel pipes in the manufacturing of machinery and equipment stems from their strength, durability, and versatility. Whether it be for hydraulic systems, structural support, or material transportation, steel pipes form an integral component that significantly contributes to the efficiency and dependability of machinery across various industries.

- Q: Can steel pipes be used for conveying corrosive substances?

- No, steel pipes are not recommended for conveying corrosive substances as they are prone to corrosion themselves.

- Q: What are the common methods for inspecting the condition of steel pipes?

- Some common methods for inspecting the condition of steel pipes include visual inspection, ultrasonic testing, magnetic particle inspection, dye penetrant inspection, and radiographic testing.

- Q: Do steel pipes expand or contract with temperature changes?

- Steel pipes expand with temperature increases and contract with temperature decreases.

Send your message to us

Seamless Boiler Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords