SCM440 Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 2005544 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel round bar:

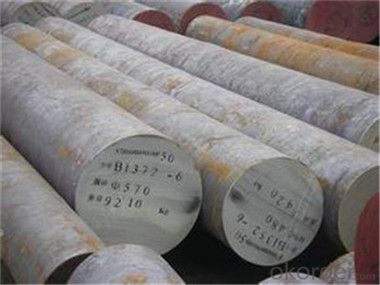

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

5. Packing: In Bundle or according to your requirements.

Festures of steel round bar:

1.Dia 80-800mm Length:2000-13000mm or as required

2.Technique:Forged

3.Delivery Time:45 days

Specifications of steel round bar:

1. Commodity: Round steel bar

3. Technical: Hot rolling

2. Length: Min. 5.8meter, according to requirement.

3. Diameter: 16mm-250mm

Images of steel round bar:

FAQ:

1. What is your main market?

We mainly export to Asia such as Japan,Korea,Thailand and North America and Middle East.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

4.Why do you choose to cooperate with us?

We have over10 years experience in this business so we are able to provide you the high quality products with the best price.

- Q: Can steel round bars be used for making connecting rods?

- Certainly, connecting rods can be crafted using steel round bars. These rods play a crucial role in internal combustion engines, necessitating robustness and endurance to endure the engine's operational forces and stresses. Steel round bars, often composed of alloy steel, exhibit exceptional mechanical traits, including elevated tensile strength, hardness, and resistance to fatigue. Consequently, they prove suitable for this purpose. Additionally, steel round bars can be conveniently machined and molded into the necessary dimensions and specifications demanded by connecting rods. As a result, employing steel round bars emerges as a widespread and dependable option for fabricating connecting rods in industries such as automotive and others.

- Q: Can steel round bars be used for making agricultural equipment?

- Yes, steel round bars can be used for making agricultural equipment. Steel is a strong and durable material that can withstand heavy use and provide the necessary strength and stability required for agricultural equipment.

- Q: Can steel round bars be used for structural purposes?

- Yes, steel round bars can be used for structural purposes. Round bars are commonly used in construction and engineering projects for their strength and durability. They can be used as load-bearing members in buildings, bridges, and other structures, providing support and stability. Steel round bars are available in various grades and sizes, allowing for versatility in design and application. They can be easily welded, formed, and machined to meet specific project requirements, making them a popular choice for structural applications.

- Q: What are the environmental considerations of steel round bars?

- Steel round bars have several environmental considerations. Firstly, the production of steel requires a significant amount of energy, which often comes from non-renewable sources, leading to greenhouse gas emissions and contributing to climate change. Additionally, the extraction and processing of raw materials for steel production, such as iron ore and coal, can have detrimental effects on local ecosystems and habitats. Furthermore, the transportation of steel round bars can result in carbon emissions if not done efficiently. However, steel is a highly recyclable material, and the use of recycled steel in the production of round bars can help reduce environmental impact. Additionally, the durability and strength of steel make it a long-lasting material, leading to less waste in the long run.

- Q: Can steel round bars be used for making electrical components?

- Whether steel round bars can be used for making certain electrical components depends on the specific requirements and applications. Steel is a versatile material that possesses good electrical conductivity and high durability, making it well-suited for a variety of electrical applications. However, when it comes to components that necessitate specific electrical properties or insulation, copper or aluminum may be more commonly utilized. Furthermore, in order to prevent corrosion or enhance electrical conductivity, it may be necessary to subject steel round bars to surface treatments or coatings. Ultimately, the appropriateness of utilizing steel round bars for manufacturing electrical components should be evaluated in accordance with the specific requirements and regulations of the intended application.

- Q: How are steel round bars tested for quality?

- Steel round bars are tested for quality through various methods such as visual inspection, dimensional checks, surface defects detection, mechanical testing, and chemical analysis. These tests ensure that the steel bars meet the required standards for strength, durability, and composition, ensuring their suitability for specific applications.

- Q: Can steel round bars be used for making renewable energy systems?

- Indeed, the utilization of steel round bars is feasible for the production of renewable energy systems. Steel, being a versatile material, finds extensive usage across multiple industries, including the renewable energy sector. Its robustness, longevity, and resistance against corrosion render it an ideal choice for fabricating frameworks, support structures, and components of renewable energy systems. For instance, steel round bars serve as an excellent building material for manufacturing wind turbine towers, solar panel frames, and support structures for hydroelectric power systems. Wind turbine towers necessitate a sturdy and stable structure to bear the weight of the turbine and endure the forces exerted by the wind. In this regard, steel round bars provide the requisite strength and stability, thereby ensuring the safety and efficiency of wind turbines. Similarly, solar panel frames require a sturdy construction capable of supporting the panels' weight and withstanding adverse weather conditions. Steel round bars can be employed to construct durable frames that securely hold the solar panels in place. Moreover, in the context of hydroelectric power systems, steel round bars prove invaluable in erecting support structures for various components like turbines, generators, and penstocks. Given the colossal pressure and force exerted by water flow, these structures need to possess the necessary durability and strength, making steel an exceptional choice for this purpose. All in all, steel round bars represent a dependable and frequently employed material in the construction of renewable energy systems. Their strength, durability, and resistance to corrosion render them suitable for diverse applications, thereby contributing to the long-term viability and sustainability of renewable energy sources.

- Q: What is the maximum nitrogen content allowed for steel round bars?

- The maximum nitrogen content allowed for steel round bars varies depending on the specific steel grade and application requirements. However, in general, the nitrogen content is typically limited to around 0.025-0.035% to maintain the desired mechanical properties and avoid detrimental effects on the material's performance.

- Q: Can steel round bars be used in the production of gears?

- Indeed, gears can be produced using steel round bars. The utilization of steel round bars as a primary material in the production of gears is quite common due to their remarkable strength, endurance, and capacity to endure substantial loads and extreme temperatures. These round bars can be either machined or forged into the desired gear configuration, guaranteeing precise measurements and precise tooth profiles. Additionally, steel round bars exhibit exceptional resistance to wear and can be subjected to heat treatment to further augment their mechanical qualities. Consequently, they are a suitable option for an array of gear types, encompassing spur gears, helical gears, bevel gears, and worm gears.

- Q: Can steel round bars be used in the production of construction equipment?

- Steel round bars are indeed capable of being utilized in the production of construction equipment. The construction industry frequently relies on steel round bars for their exceptional characteristics, including strength, durability, and versatility. These bars can be effectively employed in the creation of various construction equipment components, such as axles, shafts, gears, and structural supports. Thanks to their remarkable tensile strength, steel round bars ensure that the equipment can effectively endure heavy loads and challenging operating conditions. Furthermore, their machinability and weldability render them highly suitable for the fabrication processes involved in manufacturing construction equipment. All in all, steel round bars represent a reliable and extensively used material within the construction industry for the production of construction equipment.

Send your message to us

SCM440 Forged or Hot Rolled Sae 4140 Alloy Steel Round Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 123 m.t.

- Supply Capability:

- 2005544 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords