Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

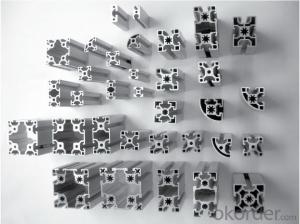

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Are aluminum profiles suitable for curtain walls and facades?

- Curtain walls and facades benefit greatly from the use of aluminum profiles, given their lightweight, durable, and versatile nature. Firstly, these profiles exhibit exceptional strength and structural integrity, enabling them to withstand various weather conditions and forces such as wind loads and seismic activity. Consequently, they prove ideal for applications where structural stability is paramount. Moreover, aluminum boasts remarkable resistance to corrosion, making it an essential attribute for exterior applications. Its resistance to rust and deterioration when exposed to moisture and other environmental factors ensures the longevity and durability of curtain walls and facades. Furthermore, aluminum profiles offer remarkable design flexibility, as they can be easily extruded into different shapes and sizes. This versatility allows for the creation of visually appealing and unique curtain wall systems and facades. Additionally, aluminum's high strength-to-weight ratio facilitates the construction of expansive glazed areas while minimizing the overall weight of the structure. Installation and maintenance of aluminum profiles are also simple and straightforward. They can be prefabricated and assembled off-site, resulting in reduced on-site construction time and costs. Moreover, aluminum requires minimal maintenance, typically only necessitating occasional cleaning to preserve its appearance and functionality. Furthermore, aluminum is a sustainable material, fully recyclable and capable of being reused and repurposed at the end of its lifecycle. This characteristic significantly reduces waste and environmental impact, aligning with the increasing demand for eco-friendly and sustainable building practices. In conclusion, the numerous advantages of aluminum profiles, including their strength, durability, corrosion resistance, design flexibility, ease of installation and maintenance, as well as their sustainability, make them highly suitable for curtain walls and facades. Architects, engineers, and building owners often choose aluminum profiles for these applications due to the benefits they offer.

- Q: Can aluminum profiles be used for curtain wall systems?

- Yes, aluminum profiles can be used for curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durability, and flexibility in design. It offers excellent structural integrity, weather resistance, and thermal performance, making it suitable for creating large glazed facades in buildings. Additionally, aluminum profiles can be easily fabricated, allowing for customization and integration of various components in curtain wall systems.

- Q: Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and easy fabrication. It can be used in the construction of train bodies, windows, doors, and various structural components. Additionally, aluminum profiles are recyclable, making them environmentally friendly and cost-effective for transportation projects.

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: Which price is expensive for aluminum profiles 6063-T6 and 6063-T5?

- 2.1 first digit: indicates the main addition of alloying elements.1: pure aluminum2: mainly adds alloy element to copper3: mainly adds alloying elements manganese or manganese and magnesium4: mainly adds alloy element to silicon5: mainly adds alloying elements to magnesium6: mainly adds alloy elements to silicon and magnesiumThe main additions of 7: alloy elements are zinc and magnesium8: does not belong to the new alloy

- Q: The aluminum and Fenglv aluminum material which is better suited for doors and windows

- Al Feng is one of the ten famous material, certainly no problem. But Feng packaging is too thick, high cost. To do the doors and windows of the aluminum used to choose cost-effective, as a special material for the sale of aluminum, I have the following recommendations: 1. The window wheel is good, and the pressed glass should be durable and corrosion resistant. 2. doors and windows sealing performance better, 3. pages to be matched with materials, gauze or rust, and thickness and density better than 4. The cost performance is high, the surface treatment layer of the profile is electrophoresis, and the electrophoresis layer should be thick. 5. The mounting frame needs to be hit to the horizontal line.

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight and durable material that is commonly used in various industries, including playground equipment manufacturing. It is known for its strength and resistance to corrosion, making it suitable for outdoor applications. Aluminum profiles provide structural stability and can withstand the weight and forces exerted during play. Additionally, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the playground equipment. The versatility of aluminum allows for the creation of various shapes and designs, providing endless possibilities for innovative and attractive playground structures. Overall, aluminum profiles are a suitable choice for playground equipment due to their strength, durability, and safety features.

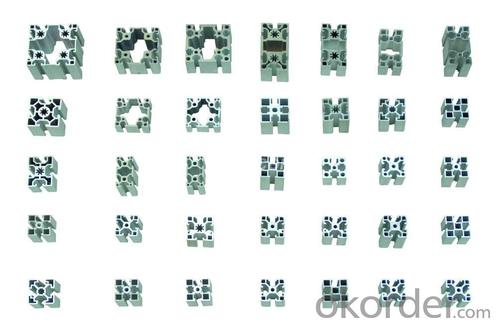

- Q: What are the different shapes available for aluminum profile cross-sections?

- There are several different shapes available for aluminum profile cross-sections, depending on the specific application and requirements. Some common shapes include: 1. Square: This shape features equal sides and right angles, making it suitable for applications where stability and strength are important, such as structural framing. 2. Rectangular: Similar to square profiles, rectangular profiles have unequal sides and can be used in a wide range of applications, including enclosures, frames, and supports. 3. T-shaped: This shape consists of a central vertical section with a horizontal section extending from one side, resembling the letter "T." T-shaped profiles are often used for joining two components or for providing additional support to structures. 4. L-shaped: L-shaped profiles have a 90-degree angle and are commonly utilized as brackets, corner reinforcements, or frame components. 5. Round: Round aluminum profiles have a circular cross-section and are frequently employed in applications where a smooth, curved appearance is desired, such as handrails, furniture, or decorative elements. 6. I-beam: Resembling the letter "I," these profiles have a central vertical section (known as the web) and two horizontal sections (known as the flanges). I-beams are widely used in construction and structural engineering due to their high strength-to-weight ratio. 7. U-channel: U-channel profiles have a U-shaped cross-section and are often used as edge protectors, trim, or guides. They can also be utilized as tracks for sliding doors or as reinforcement beams. 8. Hexagonal: Hexagonal profiles have six sides and can be used in applications where increased strength and rigidity are required, such as machinery frames or support structures. These are just a few examples of the different shapes available for aluminum profile cross-sections. It is important to choose the most appropriate shape based on the specific requirements of the intended application to ensure optimal performance and functionality.

- Q: What are the advantages of using aluminum profiles in the telecommunications industry?

- Aluminum profiles offer numerous benefits for the telecommunications industry. Firstly, they possess a combination of lightweight and robust qualities, making them ideal for constructing infrastructure like antenna towers and satellite dishes. Their lightweight nature facilitates easy transportation and installation, resulting in time and cost savings. Secondly, aluminum profiles boast exceptional resistance to corrosion. This property is of utmost importance in the telecommunications industry, where exposure to harsh weather conditions and corrosive elements such as saltwater is common. Aluminum profiles can withstand these conditions without deterioration, guaranteeing the longevity and reliability of telecommunication equipment. Moreover, aluminum profiles are highly adaptable and can be easily tailored to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for the creation of intricate structures capable of accommodating different telecommunications equipment. This versatility streamlines the integration of various components and simplifies the installation and maintenance processes. Additionally, aluminum profiles possess excellent thermal conductivity, a crucial characteristic in the telecommunications industry. As telecommunication equipment generates heat during operation, effective heat dissipation is essential to prevent overheating and equipment failure. Aluminum profiles efficiently dissipate heat, ensuring optimal performance and prolonged lifespan of telecommunication devices. Finally, aluminum is a sustainable and environmentally friendly material. It is entirely recyclable, meaning that old or damaged aluminum profiles can be recycled and transformed into new products, thereby minimizing waste and reducing the environmental footprint. By incorporating aluminum profiles into their operations, the telecommunications industry can contribute to sustainability efforts. In summary, the advantages of utilizing aluminum profiles in the telecommunications industry encompass their lightweight yet sturdy nature, corrosion resistance, adaptability, thermal conductivity, and sustainability. These characteristics make aluminum profiles an excellent choice for constructing telecommunication infrastructure, ensuring reliable performance, and minimizing environmental impact.

Send your message to us

Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords