Schedule 40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335P91 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Descriptions:

1. Commodity Name: Schedule 40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335P91

2. Standard: API,GB,ASTM,ASME,DIN

3. Quality grade: 10#, 20#, A106B, A53B, API 5L B, Q235, Q345, ST37-2, ST 45, ST52.etc.

4. Dimension:

OD: 1/2"-24"

WT: 2.5-80mm, SCH10~SCH40~XXL

Length: 5.8m,6m,8m,9m,12m

5. Technique: Hot Rolled/Cold Rolled/ Cold Drawn

6. Application:

Carbon seamless steel pipes are widely used in gas, water and oil, transpotation;constructions;Bridge,highway,windows of model steel door; building materials;fences;heating facilities Fluid Pipe;conduit pipe,scaffolding pipe.etc.

7. Payment Terms: L/C D/A D/P T/T

8. Packing and shipment

Packaged in bundles,as per customers' requirements, it can also bepackagesd as beveled ends, typed marking, black painting, plastic caps protection,woven bags packing

For 20" container the max length is 5.8m; For 40" container the max length is 12m. other options are available based on customer requests. Please discuss when placing orders.

Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

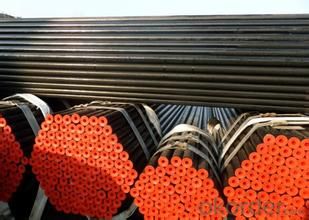

Seamless Steel Tubes Image

FAQ of Seamless Tube

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard. If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

We are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you have any question, pls feel free to contact us !

- Q:How do steel pipes perform in high-altitude applications?

- Steel pipes perform well in high-altitude applications due to their inherent strength and durability. The high tensile strength of steel allows it to withstand the harsh conditions and extreme temperature variations experienced at high altitudes. Furthermore, steel pipes are resistant to corrosion, making them suitable for use in high-altitude environments where exposure to moisture and atmospheric gases is common. Overall, steel pipes are a reliable choice for various high-altitude applications, including oil and gas transportation, construction, and infrastructure development.

- Q:What is the difference between steel pipe and concrete pipe?

- Steel pipe and concrete pipe are both commonly used for various applications, but they differ significantly in their material composition and properties. Firstly, the main difference lies in the materials used to manufacture these pipes. Steel pipes are made from steel, which is an alloy of iron and carbon. On the other hand, concrete pipes are made from a mixture of cement, aggregate (such as sand or gravel), and water. Secondly, steel pipes are known for their strength and durability. They can withstand high pressure, making them suitable for applications that require transporting fluids or gases under high pressure. Steel pipes also have a high resistance to corrosion, which is advantageous in environments where the pipe is exposed to moisture or chemicals. In contrast, concrete pipes are not as strong as steel pipes and are more prone to cracking or damage under high pressure. However, they are still capable of handling moderate pressure loads and are often used for drainage systems or sewage applications. Another significant difference is the installation process. Steel pipes are typically joined together using welding techniques, such as butt welding or socket welding. This creates a seamless and strong connection between the pipes. On the other hand, concrete pipes are often installed using rubber or gasketed joints, which are easier to assemble and disassemble. Cost is another factor where steel and concrete pipes differ. Steel pipes tend to be more expensive due to the higher cost of steel as a raw material and the additional labor required for welding and fabrication. Concrete pipes, on the other hand, are generally more cost-effective as the materials used in their production are more readily available and the installation process is simpler. In summary, the main differences between steel pipes and concrete pipes lie in their material composition, strength, resistance to corrosion, installation process, and cost. Steel pipes offer superior strength and durability, making them suitable for high-pressure applications and environments prone to corrosion. Concrete pipes, while not as strong, are cost-effective and commonly used for drainage systems or sewage applications.

- Q:What are the safety precautions for handling steel pipes?

- To prevent accidents and minimize the risk of injury when dealing with steel pipes, it is crucial to implement various safety measures. Consider the following key safety precautions: 1. Personal Protective Equipment (PPE): Ensure that you wear suitable PPE, such as safety glasses, hard hats, steel-toed boots, and gloves. This will shield you from potential hazards, including falling objects, sharp edges, or chemical spills. 2. Proper Lifting Techniques: Employ correct lifting techniques to avoid strain or back injuries when lifting steel pipes. Bend your knees, maintain a straight back, and use your legs instead of your back to lift. Seek assistance or employ mechanical lifting equipment if the pipe is too heavy. 3. Secure Storage and Stacking: Organize the storage of steel pipes meticulously, ensuring that they are stacked and secured appropriately. Utilize suitable storage methods like racks or pallets to prevent pipes from rolling or falling. Avoid excessive stacking to maintain stability. 4. Inspect for Defects: Prior to handling steel pipes, examine them for defects like cracks, corrosion, or dents. Identifying and removing defective pipes is vital as they can pose serious safety risks. 5. Use Appropriate Handling Equipment: When moving or transporting steel pipes, make use of suitable equipment like forklifts, cranes, or hoists. Verify that the equipment is in good working condition and always adhere to the manufacturer's guidelines for safe operation. 6. Secure Transportation: When transporting steel pipes by vehicle, ensure that they are securely fastened to prevent shifting or falling during transit. Use restraints like straps or chains to secure the load. 7. Watch for Sharp Edges: Exercise caution when handling steel pipes as they may have sharp edges that can cause cuts or injuries. Wear gloves to protect your hands. 8. Communication and Training: Establish effective communication with your team members to ensure that everyone understands the correct handling procedures and safety precautions. Conduct training sessions on safe lifting techniques, equipment operation, and hazard identification. 9. Maintain a Clean Work Area: Keep the work area clean and free from debris, oil, or other slippery substances that may lead to slips or falls. 10. Follow Safety Guidelines: Always adhere to safety guidelines and procedures set by your organization or relevant regulatory authorities. These guidelines may include additional precautions specific to your work environment. By diligently following these safety precautions, you can significantly reduce the likelihood of accidents and injuries when handling steel pipes. Remember, prioritizing safety is paramount in any work environment.

- Q:How are steel pipes used in the construction of underground utilities?

- Steel pipes are commonly used in the construction of underground utilities due to their durability and strength. They are used to transport various substances such as water, gas, and sewage underground, ensuring efficient and reliable distribution. Steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for underground applications where they need to withstand the weight of the soil and other environmental factors. Additionally, steel pipes are easy to install and maintain, making them a cost-effective choice for underground utility construction projects.

- Q:How are steel pipes used in the power generation sector?

- Steel pipes are widely used in the power generation sector for various purposes. They are primarily used for transporting fluids, such as water, steam, and oil, as well as gases, in power plants. Steel pipes are also used for constructing pipelines that carry fuel, like natural gas or coal, to power plants. Additionally, they are used for structural purposes, supporting equipment, and maintaining the overall integrity of power generation facilities.

- Q:Can steel pipes be used for transporting chemicals?

- Yes, steel pipes can be used for transporting chemicals. Steel pipes are known for their strength and durability, making them suitable for various applications, including the transportation of chemicals. Additionally, steel pipes are resistant to corrosion, which is crucial when dealing with potentially corrosive substances. However, it is important to ensure that the specific type of steel used in the pipes is compatible with the chemicals being transported to prevent any reactions or contamination.

- Q:What are the different methods of threading steel pipes?

- There are several methods of threading steel pipes, including manual threading, machine threading, and dielectric threading. Manual threading involves using a manual pipe threader or a handheld die to create the threads on the pipe. Machine threading, on the other hand, utilizes power-driven machines that can thread multiple pipes simultaneously, increasing efficiency and accuracy. Dielectric threading is a specialized method that uses a high-frequency electrical current to generate threads on the pipe, which is commonly used for stainless steel pipes.

- Q:How are steel pipes classified according to their wall thickness?

- Steel pipes are classified according to their wall thickness into three categories: standard weight, extra-strong, and double extra-strong.

- Q:How are steel pipes protected from corrosion in corrosive environments?

- Steel pipes are protected from corrosion in corrosive environments through various methods such as applying protective coatings, using cathodic protection systems, and implementing corrosion inhibitors.

- Q:How are steel pipes measured and categorized?

- Steel pipes are typically measured and categorized based on their outer diameter (OD) and wall thickness. The OD is measured in inches or millimeters, while the wall thickness is measured in inches or centimeters. Pipes are further categorized based on their schedule, which refers to the wall thickness and determines the pressure rating of the pipe. The schedule is denoted by a letter or number, such as Schedule 40 or Sch 80. These measurements and categorizations help in selecting the appropriate steel pipe for different applications and ensure compatibility with fittings and other components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Schedule 40 ASTM A53 API 5L GR.B Carbon Seamless Steel Tubes A335P91 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords