All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures can be taken to protect steel pipes from physical damage during excavation and construction?

There are several measures that can be taken to protect steel pipes from physical damage during excavation and construction. Firstly, proper planning and surveying of the site can help identify the location of existing pipelines, ensuring that construction activities avoid these areas. Secondly, using suitable protective materials such as plastic or rubber sleeves around the steel pipes can help shield them from potential damage caused by heavy machinery or impact. Additionally, implementing clear signage and fencing around the construction site can alert workers and equipment operators about the presence of buried pipes, reducing the risk of accidental damage. Regular inspections and maintenance of the pipes during and after construction are also crucial to identify any potential issues early on and prevent further damage.

What is the role of steel pipes in the automotive industry for fuel efficiency and emissions control?

Steel pipes play a crucial role in the automotive industry for fuel efficiency and emissions control. They are used in the exhaust system to efficiently transport and direct exhaust gases away from the engine, minimizing back pressure and optimizing performance. Additionally, steel pipes contribute to emissions control by providing a durable and corrosion-resistant solution, ensuring the longevity and effectiveness of emission control devices such as catalytic converters. Overall, steel pipes aid in achieving better fuel efficiency and reducing harmful emissions in vehicles.

How do you determine the optimal spacing for expansion joints in long steel pipelines?

The optimal spacing for expansion joints in long steel pipelines is determined by considering factors such as the temperature changes the pipeline will experience, the material properties of the steel, and the expected movements caused by thermal expansion and contraction. Additionally, pipeline design codes and standards provide guidelines for calculating the required spacing based on these factors to ensure the safe and efficient operation of the pipeline.

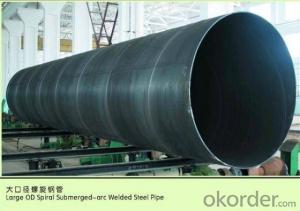

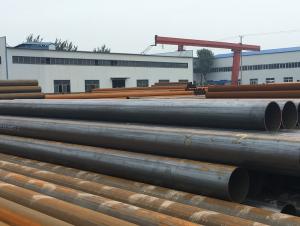

Wholesale Steel Pipes from supplier in Afghanistan

With our dedicated team of professionals, we strive to deliver high-quality Steel Pipes that meet international standards and are suitable for various applications such as construction, infrastructure, oil and gas, and water supply. Our products are sourced from reputable manufacturers and undergo strict quality control measures to ensure durability and reliability.

In addition to supplying Steel Pipes, we also provide sales and quotation services to assist our customers in selecting the right products for their specific needs. Our experienced sales team is available to answer any inquiries and provide technical support to ensure a smooth and efficient purchasing process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer a complete one-stop procurement solution for Steel Pipes in Afghanistan. This includes timely delivery, competitive pricing, and customized solutions tailored to your requirements.

Our years of market presence and experience in Afghanistan have enabled us to develop strong relationships with local suppliers and contractors. This allows us to provide valuable insights and expertise to enhance the success of your projects. We understand the unique challenges and requirements of the Afghan market and are committed to delivering exceptional service and support.

Whether you require Steel Pipes for a small-scale project or a large infrastructure development, we are dedicated to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and let us be your trusted partner for all your Steel Pipes needs in Afghanistan.

In addition to supplying Steel Pipes, we also provide sales and quotation services to assist our customers in selecting the right products for their specific needs. Our experienced sales team is available to answer any inquiries and provide technical support to ensure a smooth and efficient purchasing process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer a complete one-stop procurement solution for Steel Pipes in Afghanistan. This includes timely delivery, competitive pricing, and customized solutions tailored to your requirements.

Our years of market presence and experience in Afghanistan have enabled us to develop strong relationships with local suppliers and contractors. This allows us to provide valuable insights and expertise to enhance the success of your projects. We understand the unique challenges and requirements of the Afghan market and are committed to delivering exceptional service and support.

Whether you require Steel Pipes for a small-scale project or a large infrastructure development, we are dedicated to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and let us be your trusted partner for all your Steel Pipes needs in Afghanistan.