Scale Diamond Plate Aluminum Sheets - Low Price and Lightweight Oxidation Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

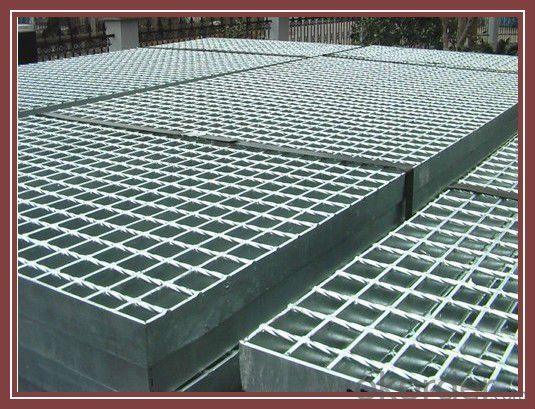

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Drainage trench cover Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: What kind of paint would you like to paint on the aluminum plate?

- Nitro paint, polyester paint can be mainly your base, you should use atomic ash treatment before you can use, otherwise it will peel off

- Q: This question asks about the impact of using aluminum sheets on the aesthetic appeal of a building.

- <p>Aluminum sheets can significantly enhance the appearance of a building due to their versatility, durability, and modern aesthetic. They offer a sleek, clean look and can be easily shaped into various designs, adding a contemporary feel. The material's resistance to corrosion and weathering ensures that the building maintains its appearance over time. Additionally, aluminum sheets can be coated with various colors and finishes, allowing for customization and the ability to blend with or stand out from the surrounding architecture.</p>

- Q: This question asks if aluminum sheets can be recycled repeatedly without losing their quality.

- <p>Yes, aluminum sheets can be recycled multiple times without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the material's properties. In fact, recycled aluminum requires significantly less energy to produce compared to mining and refining new aluminum from bauxite ore. This makes aluminum recycling an environmentally friendly and cost-effective process, contributing to sustainability and reducing the demand for raw materials.</p>

- Q: Are aluminum sheets suitable for architectural applications?

- Architectural applications can indeed benefit from the suitability of aluminum sheets. Aluminum, being a versatile material, offers numerous advantages for architectural projects. It possesses a lightweight quality while still being strong, making it easy to handle and install. Furthermore, its resistance to corrosion makes it ideal for outdoor applications that are exposed to the elements. The malleability of aluminum sheets allows them to be easily formed into different shapes and sizes, enabling architects to create innovative and creative designs. These sheets find their use in various architectural applications such as cladding, roofing, facades, as well as interior elements including ceilings, partitions, and decorative components. Moreover, architects have the freedom to choose from a wide range of finishes for aluminum sheets, including anodized, painted, or coated. These finishes not only enhance the aesthetics of the projects but also improve the material's durability and color retention, thereby ensuring long-term performance and minimal maintenance requirements. Beyond these advantages, aluminum is also a sustainable material. It is fully recyclable and has a lower carbon footprint compared to other metals. This aligns with the growing emphasis on environmentally-friendly construction practices in the architectural industry. In conclusion, due to their lightweight nature, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes, aluminum sheets are highly suitable for architectural applications. Architects can confidently incorporate aluminum sheets into their designs, resulting in visually appealing and durable structures.

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies based on the specific alloy and temper of the material. In general, aluminum alloys have a lower shear strength compared to steels, but higher than most other non-ferrous metals. The shear strength can range from around 30 to 60 MPa (MegaPascals) for commonly used aluminum alloys in sheet form. However, it should be noted that these values can change depending on factors like thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to refer to the specific material datasheet or reach out to the manufacturer for accurate and detailed information regarding the shear strength of a particular aluminum sheet.

- Q: Can aluminum sheet be used for packaging applications?

- Yes, aluminum sheet can definitely be used for packaging applications. Aluminum is widely used in the packaging industry due to its excellent properties. It is lightweight, strong, durable, and malleable, making it ideal for packaging various products. Aluminum sheets can be easily formed into different shapes and sizes, allowing for custom packaging solutions. Additionally, aluminum has excellent barrier properties, providing protection against moisture, gases, and light, which helps to maintain the freshness and quality of the packaged goods. Furthermore, aluminum is non-toxic and can be easily recycled, making it a sustainable choice for packaging applications. Overall, aluminum sheet is a versatile and reliable material for packaging various items, including food, beverages, pharmaceuticals, cosmetics, and many others.

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- . The cans will always be sharp. It is possible sand or file aluminum, you will need a brush to clean the sandpaper on file. You could try folding edges to possibly remove some of the some of the sharpness.

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

Send your message to us

Scale Diamond Plate Aluminum Sheets - Low Price and Lightweight Oxidation Aluminum Alloy Gratings Stair Tread Steps

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords