SBS Modified Bitumen Waterproofing Roofing Rolling Membrane For Bridge China Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product description:

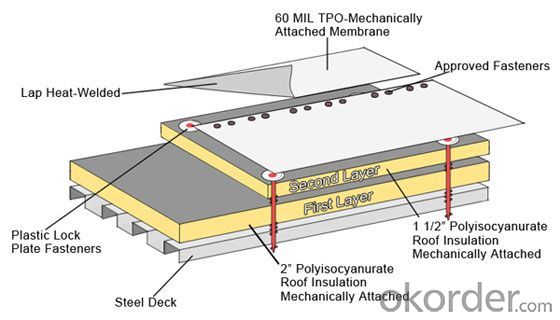

sbs waterproof membrane take the “Skin” type waterproof thought, according to the features of construction site, on the basis of width elastomeric modified bitumen waterproofing membrane, combining with features of wet-application self-adhesive membrane, use advanced equipment to produce 2 meters width that WP-SBS wet-application width elastomeric modified bitumen waterproofing membrane (Hereinafter referred to: WP-SBS membrane).WP-SBS is made of bitumen modified with Styrene-Butadiene- Styrene (SBS)as dipping and painting. Its upper surface covers PE membrane and color sand or schist, and lower surface is made of isolation material. Products correspond to the national standards GB18242-2008(elastomeric modified bitumen waterproofing membrane), paste by cement or cement mortar, and construct on the wet base, achieving tight and full adhesion with substrates, eliminating fluid-channeling layer, all above contribute to making a reliable “Skin” type waterproof system, which is a breakthrough innovation in ordinary modified bitumen membrane.

Characteristic

1.Good impermeability

2.Possess good tensile strength, elongation and size stability which could be well suited the substrate distortion and crack.

3.Good performance in anti-strength, anti-resistance , anti-erosion, anti-mildew, anti-weathering

4.SBS modified bitumen membrane is specially being applied in the cold area with low temperature, while APP modified bitumen membrane is applied in the area with high temperature.

5.Convenient installation

Applicable scope:

It is widely used for civil building roofing, underground, bridge, parking, pool, tunnel in the line of waterproofing and dampproofing, especially for the building under high temperature.

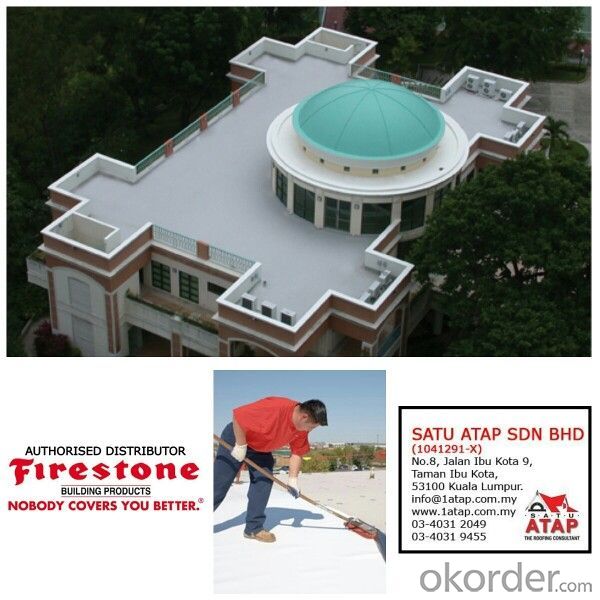

Application

The needle-punched polyester is widely used as the carrier for waterproofing membrane production. The membrane made withneedle-punched polyester matis widely used for: Construction waterproofing; Moisture-proof in roof engineering, underground engineering, indoor ground, etc;Corrosion resistance for water pool or building bases.

Our Services

1.If you need some advises for the waterproof construction, we have the best engineer to serve you.

2.We send the free samples to you by freight collect.

3.We will guarantee the quality and the competitive price.

4.We will give you the best packaging and safe shipping.

5.If any problem, we will always be right here waiting for you.

Packaging & Shipping

| Packing | Woven bag/PE bag packing or as customer request |

| Shipping | FOB Changsha,customized shipping terms and oppointed port accepted |

Technical parameter

| Item | Specifications | ||||||||

| Geotextile Unit Weight (g/m²) | 300 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | |

| Geomembrane Thickness (mm) | 0.25-0.35 | 0.30-0.50 | |||||||

| Nominal Fracture Strength (KN/m) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Breaking Strength (KN/m,≥,LD/TD) | 2.50 | 7.50 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Standard Intensity Corresponding Elongation Rate (%) | 30~100 | ||||||||

| CBR Burst Strength (KN,≥) | 0.70 | 1.50 | 1.90 | 2.20 | 2.50 | 2.80 | 3.00 | 3.20 | |

| Longitudinal Tear Strength (KN,≥) | 0.05 | 0.25 | 0.32 | 0.40 | 0.48 | 0.56 | 0.62 | 0.70 | |

| Hydrostatic Pressve (Mpa) | See List Below | ||||||||

| Peel Strength (N/cm,≥) | 6 | ||||||||

| Vertical Permeability Coefficient (cm/s) | According to design or contract mentioned. | ||||||||

| Width Variation (%) | -1.00 | ||||||||

| Item | Geomembrane Thickness (mm) | ||||||||

| 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 | 1.00 | ||

| Hydrostatic Pressve (Mpa) | One geotextiles with one geomembrane | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| Two geotextiles with one geomembrane | 0.50 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 | 1.80 | |

Professional test machines ensure the products qualified roduct certifications

roduct certifications

Inquiry Note

How to send an effective inquiry for saving your time?

product show

FAQ

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Special considerations must be taken into account when installing a waterproofing membrane in seismic zones due to the risk of earthquakes and ground movements. To withstand the potential movements and vibrations caused by seismic activities, it is crucial to ensure that the membrane is capable of withstanding stress and strain. When installing a waterproofing membrane in seismic zones, several factors should be considered: 1. Flexibility: The membrane should possess sufficient flexibility to accommodate the movement of the building structure during an earthquake. It should be able to stretch, contract, and withstand dynamic forces without tearing or compromising its waterproofing properties. 2. Compatibility: It is important to select a waterproofing membrane that is compatible with the building materials and systems used in seismic zones. This ensures that the membrane bonds well with the substrate and other construction components, creating a seamless and robust waterproofing system. 3. Reinforcement: In areas with high seismic activity, it is recommended to reinforce the waterproofing membrane with additional layers or reinforcements. This can be achieved by incorporating a fabric or mesh layer to enhance the membrane's tensile strength and resistance to tearing caused by seismic movements. 4. Proper installation techniques: The installation of the waterproofing membrane in seismic zones should adhere to specific guidelines and techniques to ensure its effectiveness. This may involve using specific adhesives, primers, or mechanical fastening systems to securely install the membrane. 5. Quality control: Regular inspections and quality control measures should be implemented during and after the installation process. This allows for the identification of any potential issues or deficiencies in the waterproofing system, enabling prompt repairs or adjustments to be made. By addressing these special considerations, the installation of a waterproofing membrane in seismic zones can effectively safeguard the building structure against water intrusion and potential damage caused by earthquakes. Consultation with experienced professionals and adherence to industry standards and guidelines are imperative for a successful installation in these challenging environments.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Certainly, stadiums and arenas can absolutely benefit from the utilization of waterproofing membranes. In fact, it is highly advisable to employ these membranes in these expansive constructions to shield them from water harm and leaks. These grand structures are frequently subjected to diverse weather conditions, including substantial rainfall and snowfall, which have the potential to infiltrate the edifice with water. A waterproofing membrane functions as a barricade, impeding water from entering the building and causing harm to its structural elements, such as concrete or steel. It aids in upholding the structure's integrity and protracting its lifespan. Moreover, waterproofing membranes also offer protection against other forms of moisture, such as condensation and humidity, which can result in mold growth and materials deterioration. Therefore, the application of a waterproofing membrane is an essential measure in guaranteeing the endurance and longevity of stadiums and arenas.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Indeed, adobe block surfaces can be treated with a waterproofing membrane. These blocks, composed of a blend of clay, sand, and straw, are prone to water damage. By applying a waterproofing membrane, the infiltration of water can be prevented, thus safeguarding the adobe blocks against various moisture-related problems like cracking, erosion, or mold formation. It is essential to verify that the waterproofing membrane is suitable for adobe surfaces and adhere to the manufacturer's instructions for application. Furthermore, prior to applying the membrane, it is vital to adequately prepare the surface and address any preexisting damages to ensure optimal performance.

- Q: Are waterproofing membranes suitable for historical preservation projects?

- Waterproofing membranes can be suitable for historical preservation projects, depending on the specific circumstances and goals of the project. Waterproofing membranes are designed to provide a protective barrier against water infiltration, which can help to prevent damage to historical structures caused by moisture. In some cases, historical buildings may have existing waterproofing systems that are deteriorated or no longer effective. In these situations, the use of modern waterproofing membranes can be a viable option to protect and preserve the structure. These membranes can be installed discreetly, without altering the original appearance or architectural integrity of the building. However, it is crucial to approach the use of waterproofing membranes in historical preservation projects with caution. The potential impact on the authenticity and historical value of the structure must be carefully evaluated. Some historical buildings may have unique construction methods or materials that require specialized preservation techniques. In such cases, alternative preservation methods that do not involve the use of membranes may be more appropriate. Additionally, it is important to consider the long-term consequences and maintenance requirements of waterproofing membranes. Some membranes may have a limited lifespan, and periodic inspections and maintenance may be necessary to ensure their continued effectiveness. This ongoing maintenance should be factored into the overall preservation plan and budget. Ultimately, the decision to use waterproofing membranes in historical preservation projects should be based on a thorough assessment of the specific needs and characteristics of the building, as well as the preservation objectives. Consulting with preservation experts, architects, and engineers can help to determine the most suitable approach for each unique project.

- Q: Can a waterproofing membrane be used in interior or exterior applications?

- Yes, a waterproofing membrane can be used in both interior and exterior applications. In interior applications, such as basements or bathrooms, a waterproofing membrane can be installed on walls or floors to prevent water or moisture from seeping through. This helps to protect the underlying structure from damage caused by water intrusion. In exterior applications, a waterproofing membrane can be applied to the exterior walls or foundations of a building to prevent water from penetrating into the structure. This is especially important in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane helps to keep the interior of the building dry and free from water damage. Overall, the use of a waterproofing membrane in both interior and exterior applications is essential for ensuring the longevity and durability of a structure by protecting it from water-related issues.

- Q: Are waterproofing membranes resistant to chemical solvents?

- Waterproofing membranes are generally capable of withstanding chemical solvents. They are designed to endure exposure to different chemicals, including solvents. These membranes are formulated to create a barrier against moisture and safeguard against damage caused by chemical contact. The ability to resist chemical solvents is a crucial characteristic of waterproofing membranes, as it guarantees their durability and effectiveness in various applications like construction, roofing, and below-grade waterproofing. However, it is important to mention that the specific resistance of a waterproofing membrane to chemical solvents may differ based on the type and brand of membrane used. Therefore, it is always advisable to refer to the manufacturer's guidelines for detailed information on chemical resistance.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can a waterproofing membrane be used for food processing facilities?

- Indeed, food processing facilities can utilize waterproofing membranes. These membranes are widely employed across various industries, including food processing, to safeguard against water intrusion and moisture-related harm. To safeguard the building structure, waterproofing membranes can be installed on floors, walls, and ceilings in food processing facilities, where maintaining cleanliness and hygiene is of paramount importance. By creating an effective barrier, waterproofing membranes effectively seal surfaces, thwarting the proliferation of mold, mildew, and bacteria that could potentially contaminate food products. Furthermore, they aid in upholding a clean and dry environment, thereby diminishing the risk of slips, falls, and accidents that could result from wet surfaces. Water-intensive processes such as cleaning, washing, and sanitizing are prevalent in food processing facilities, underscoring the need for a dependable waterproofing system. Additionally, waterproofing membranes can exhibit resistance to chemicals, oils, and other substances commonly utilized in food processing, thereby ensuring longevity and protection. It is essential to emphasize that when selecting a waterproofing membrane for a food processing facility, adherence to industry standards and regulations is imperative. The chosen membrane must be food-grade and possess certification ensuring its safety during contact with food products, thus averting any potential contamination concerns. Ultimately, the implementation of a waterproofing membrane within food processing facilities is instrumental in preserving hygienic conditions, fortifying the building structure, and securing compliance with health and safety regulations.

- Q: Can a waterproofing membrane be used on terrazzo surfaces?

- Terrazzo surfaces can indeed benefit from the application of a waterproofing membrane. Terrazzo, a strong and adaptable flooring material composed of marble, granite, quartz, or glass chips mixed with cementitious or epoxy matrix, has a moderate resistance to water. However, it is not entirely impervious and can absorb moisture if not treated. To safeguard against water damage, staining, and discoloration, it is recommended to apply a waterproofing membrane on terrazzo surfaces. The membrane functions as a barrier, effectively preventing water and other liquids from penetrating the terrazzo, thereby enhancing its durability and maintaining its aesthetic appeal. To ensure optimal effectiveness, it is crucial to choose a waterproofing membrane that is compatible with the terrazzo material and follow the manufacturer's instructions during application.

Send your message to us

SBS Modified Bitumen Waterproofing Roofing Rolling Membrane For Bridge China Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords