sandwich panel compressed fibre cement composite board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

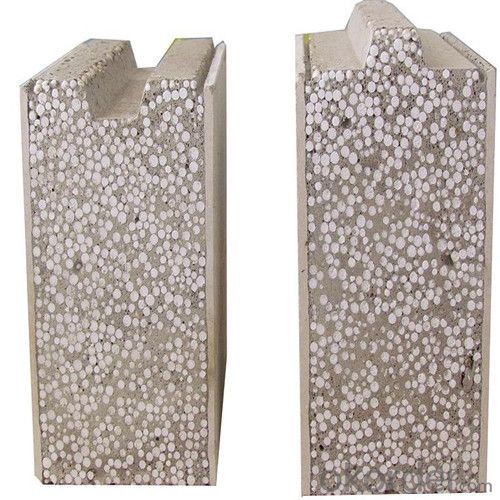

1.Product name: sandwich wall panel

2.Composition: Fibre reinforced calcium silicon board or cement calcium silicon board as panel, with cement, EPS, Fly ash as fillers and forming by one time compound.

3.Dimension(L*W*T): 1500-3000x610x60,75,90,100,120,150,180mm,general length:2270mmm,Max length : 3000mm

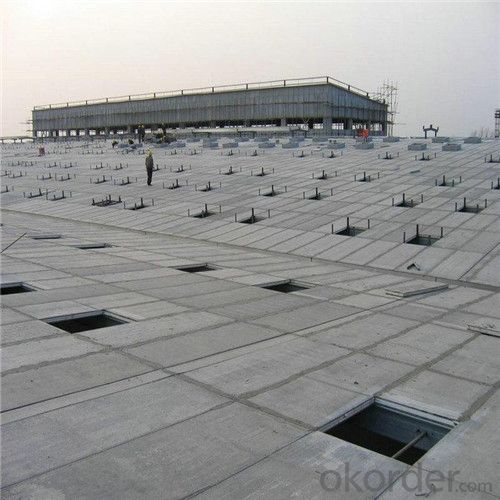

4.Usage: It can replace construction materials as red brick, clay solid brick,color-coated steel sandwich board, gypsum block, wire spatial grid structure perlite board, perlite porous board etc. Interior and exterior partition on steel or concrete structure building ,for new construction, additions or renovations, such as bank, office, hospital, school, workshop and so on.

5.Product features

Heat insulation and preservation :The feature of energy saving of Jinyi boards is mainly reflected in it’s heat preservation and insulation ,the major material is polystyrene grains and other anit-freezing and heat preserving environmental protection materials ,which could adjust the indoor temperature at a constant range thus achieving the effects of ecological adjustment .

Water-proof& fire-proof: the face panel of Jinyi energy-saving boards on both side are 4.5mm calcium silicate fire proof boards and the main material is a mixture of cement ,sand ,fly ash and so on.tests have shown that Jinyi energy saving boards have a fire proof limit of 4 hours against a high temperature of 1000°C and the incombustibility has reached National A level,besides ,these materials doesn’t give out toxic gas and perfectly meet the international environmental standard ,the tests also prove the water containers can be made by Jinyi panel with no need for plastering and the containers have no leakage at all .

Sound insulation and absorption: the inside constructional material ( EPS polystyrene grain ) function well in sound insulation and sound-absorbing .

Easy construction and time saving: For the same construction work that takes 12 people and 60 minutes to complete with traditional blocks ,only 3 people and 60 minutes will do Jinyi boards ,thus can save a lot of labor and time cost the construction part .

High Intensity and quake proof: The Jinyi energy saving boards are all with high intensity and the earthquake resistance can reach 8.5 magnitudes ,the shock resistance index is several times higher than other wall material , the boards can be nailed directly and with expansion bolt to lift and hang heavy things ,the also can be covered by ceramic tile ,wall paper and wood panel ,coating.

Space and cost saving: The thickness of Jinyi energy boards are between 60mm to 180mm ,compared with traditional blocks ,the building area is largely increased ,in the mean time ,the weight of Jinyi boards is only 1/12 that traditional wall body ,which saves the cost on construction structure a lot .

Photos:

- Q: Is polystyrene sandwich board flammable?

- In general, the benzene board is flammable, but there is a flame retardant type, is the type of self-extinguishing. Usually used as building materials. The other is basically flammable.

- Q: Color steel sandwich panel wall, you can directly spray really stone paint what is the practice

- According to the following construction methods to achieve good results: 1, in the sandwich panel (plate) on the gap to be caulking. It is recommended to use the home of the heart of the card to worry about toughness to fill the joints, and then paste the seam (master understand). 2, if directly in the sandwich panel (plate) on the batch of putty powder or spray paint really easy to drop off the phenomenon of paint, the first primer, it is recommended to use the home of the board of people worry-free putty scraping again There are), to be dry and then approved scraping putty powder. 3, spray really stone paint.

- Q: Color plate and color steel sandwich panel difference

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: What is the ESP sandwich panel

- EPS is polystyrene, which is what we call foam board Sandwich refers to the foam as the core material, the external double-sided composite material of other plates. Other plate is generally the majority of color steel plate.

- Q: With the production of sandwich panels can now control how many years?

- In general, sandwich panel covers the house! On the iron thickness of 0.4, under the thickness of 0.326, you can protect the new 10 years, no later than 2 years spray a paint, up to 25 years! Aluminized zinc is longer,

- Q: Is the foam sandwich board one meter high?

- Some we do the highest of 21 meters

- Q: Single door size is 450MM * 550MM, I would like to ask is the stone attached to the door whether it will be too heavy, is not conducive to the door hinge, hinge will withstand the living? The Thank you

- Now there are toilet available in the mall wallpaper, but also when the cabinet paper, waterproof and wearable, and what color has, including you want the marble color. ??? It can not find to buy a special indoor plastic floor. Any space in this floor can be used at home, including the bathroom wall. Waterproof, light material, natural can be used in the counter. Full color. However, your area is too small, generally no one is willing to come to do, you use their accessories to deal with their own on the line. ??? I have friends to do the film and television walls and bathroom wall, the effect is good, with the Hanhua this brand, said that the original Korean imports, you can go and see.

- Q: I don't want to gain weight, so is this a healthy one: pita bread, organic peanut butter, and organic grape jelly.

- try whole grain bread organic peanut butter and jelly thats low sodium and cholesterol

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Or with sandwich panels, and now the market is a kind of better plate, called multi-layer solid wood or multi-layer plywood, the quality carry carry, and do the wardrobe is also very high Oh

Send your message to us

sandwich panel compressed fibre cement composite board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords