Fiber cement composite wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

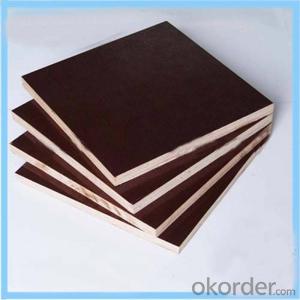

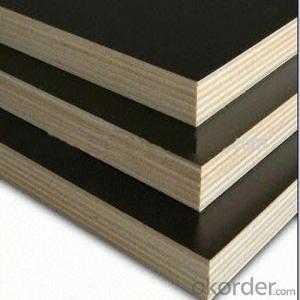

fiber cement sandwich panel

Size

1220*2440mm,Or as clients' requests

Film

Bintangor Okoume,Pine,etc

Thickness

15mm,18mm,21mm etc;

Core

Poplar, Hardwood, Birch , Combi,Eucalyptus, etc;

Tolerance

Length/width :+/-0.2mm; Thickness: +/-0.5mm

Glue

MR(water proof), MELAMINE(water proof), WBP(phenolic);

Mositure content

8%-12%

Modulus of rupture

>30MPa

Modulus of Elasticity

>6000MPa

packing

bottom is pallets, covered with plastic film,around is carton or plywood, strenghthen by steel or iron 3*6

quantity

20GP

8pallets/21M3

40GP

16pallets/42M3

40HQ

18pallets/53M3

Usage

Furniture, construction, etc

Payment

TT or L/C at sight

Delivery Time

Within 20 days receiving deposit or original L/C at sight

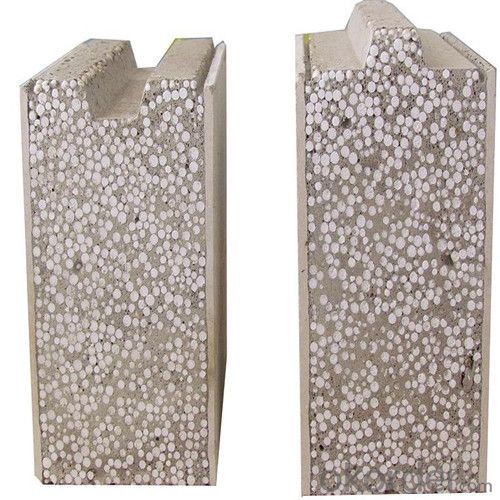

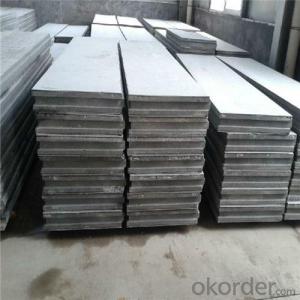

Fiber cemnt sandwich panel, light weight concrete sandwich panel

1. Composition:

Core materials: cement, EPS, and fly ash core

Surface materials: fiber reinforced calcium silicone board or cement calcium silicone board

2. Specification: (L*W*T)

1500-3000mm X 610mm X (50, 75, 100, 120,150,180mm)

fiber cement board on both sides: 5mm, 6mm, 8mm

3. Usage:

Interior and exterior partition on steel or concrete structure building,

For new construction, additions or renovations.

4. Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof and dampproff

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

- Q: What kind of support is needed

- Fix the screws on the C steel

- Q: Steel structure plant color steel sandwich panel roof design fire resistance 0.5H, need to apply fire retardant paint

- Need, the fire limit is half an hour, need to apply fire retardant coating.

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: Color steel sandwich board how much money

- First, the color plate model: roof? Wall? ?????? Second, the core material (glass wool? Rock wool? Polyurethane? Polyphenylene extrusion), thickness, density ?????? Third, the color plate thickness, origin, coating, plating (aluminum) zinc content ?????? Fourth, the amount will also affect the price to a certain extent.

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: What is the difference between the sandwich panel and the composite board?

- Metal sandwich panels are made of two-layer metal panels (or other material panels) for the surface material, insulation materials to do the core material, with adhesive composite or direct foam curing molding compound. Building insulation sheet industry in the insulation board refers to the sandwich panels, composite board is popular called. Metal composite panel in the industry refers to a layer of metal plate covered with another metal plate, in order to reduce the use of the effect (corrosion resistance, mechanical strength, etc.) under the premise of saving resources and reduce the cost of the effect.

- Q: What is the quota of the roof steel plate?

- Compression steel plate floor of the Caigang roof sandwich panels

- Q: The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

- Q: What is the difference between the board and the core board?

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than ... but generally do not choose the best! Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, ... plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

Send your message to us

Fiber cement composite wall panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords