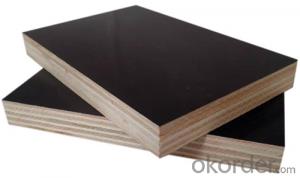

Fiber cement composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Performance Parameters: | |||||

| ltem | Unit | Thickness 125mm | Thickness 100mm | Thickness 75mm | Thickness 50mm |

| Standard of dry shrinkage value | mm/m | ≤0.6 | ≤0.52 | ≤0.49 | ≤0.46 |

| Sound insulation volume in the air | dB | ≥50 | ≥48 | ≥48 | ≥40 |

| Shockproof strength | The time of no through crack | 10 Times | 10 Times | 10 Times | 5 Times |

| Anti-bending collapsing strength | The multlple of the board's self-weight(Put pressure) | ≥6.0 | ≥6.0 | ≥6.0 | ≥6.0 |

| Hanging force | N | 1000 | 1000 | 1000 | 800 |

| Fire-resistant limit | H | 5 | 4 | 3 | 2 |

| Combustiblllty performance | Level | GB8624 A1 Level non-combustible | |||

| Coefficient of heat conductivily(W/MK) | 0.021 | ||||

| The Anti-returns(24h) | No drop of water and no damp | ||||

| Gas proof and anti-moth function | lnorganic substances have insect-resistant,gas proof and anti-moth performance | ||||

| Water permeability resistant | waterproof | ||||

| Moisture(%) | ≤9 | ||||

| Standard Specification: | |||||

| Width:610mm Length:3050/2440mm Thickness: 50/75/100/125mm | |||||

| Application Recommended: | |||||

| Widely used in non-load-bearing interior and exterior walls of buildings, commercial buildings, office partition wall,and need water proof, noise proof and moisture proof requirements place. | |||||

Fiber cemnt sandwich panel, light weight concrete sandwich panel

1. Composition:

Core materials: cement, EPS, and fly ash core

Surface materials: fiber reinforced calcium silicone board or cement calcium silicone board

2. Specification: (L*W*T)

1500-3000mm X 610mm X (50, 75, 100, 120,150,180mm)

fiber cement board on both sides: 5mm, 6mm, 8mm

3. Usage:

Interior and exterior partition on steel or concrete structure building,

For new construction, additions or renovations.

4. Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof and dampproff

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

- Q: Is the polyurethane sandwich panel and foam board flame retardant?

- On the market, the polyurethane foam flame retardant grade B1, B2, B3 three grades. Because of the cost, sandwich board with the majority of polyurethane material is B3 level, a small amount of B2 level, there are a small amount of special requirements B1 level. B1 level for the 'flame'; B2 level for the 'combustible'; B3 level for the 'flammable'. B1 grade oxygen index requirements of more than 30%; B2 level requirements of more than 26%, 26% of the following collectively referred to as B3 level. You said the flame retardant, it should be self-extinguishing from the fire. B2, B1 from the heat certainly no problem. A little better B3 (oxygen index of about 25%) can also be self-extinguishing, but more than B2 self-extinguishing time more than a few seconds. General oxygen index of less than 24%, it is difficult to self-extinguishing from the fire, will always burn, the greater the greater the burning. The The Oxygen Index: The concentration of oxygen required to stabilize the combustion in the oxygen and nitrogen gas mixture under the specified shape of the foam, the specified source of fire and the size of the flame. - For example, the better the flame retardant properties of the foam, the higher the concentration of oxygen needed to ignite the foam, the higher the oxygen index of the bubble

- Q: Extruded polystyrene board and color steel sandwich board which is better

- Each have different, simply can not be compared together Extrusion board is mainly good insulation effect, mainly for the insulation layer The color steel sandwich panels are mainly used for the production of housing, although there are insulation effect, but the insulation effect is not as extruded board (cost is also high).

- Q: Sandwich composite panel and color steel tile difference which the high cost

- Sandwich panels are also called Caigang sandwich panels, is the middle of two-layer steel plate plus polyurethane foam or rock wool building plate; color steel tile is a single layer of pressure plate. Sandwich panels are more expensive.

- Q: Hanging plate, color plate, sandwich panels, pressure plate the same?

- Sandwich panels and Caigang sandwich panels is one thing, are double-color steel plate folder folder insulation material, food production workshop with sandwich panels can

- Q: Pressure plate composite insulation board and the difference between the sandwich panels, the price difference is large? What kind of geng good for steel structure plant design?

- Composite insulation board is installed on the ground, the following layer of the board, the middle is the insulation cotton, the installation of a little trouble, the above is a layer of board. Sandwich panels are machined in the workshop of the plate, easy to install. The price difference between the two is not great. Steel plant should be based on the use of choice, sandwich panels and composite are useful. The composite board is better, but the price is also slightly more expensive.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides with the wall of the gap how waterproof ~

- If the gap is large, you can use the blowing agent to fill the tampon, and then use cement mortar wiped rounded, the surface roller waterproof coating (polyurethane waterproof coating, asphalt, etc.); Small gap, you can directly hit the silicone sealant; Above all have to ensure that the color plate fixed firmly, or if loose will damage the water

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Polyurethane foam can only achieve B1 flame retardant, the system's fire resistance by the two sides of the composite material fire resistance decision.

- Q: How to calculate the force of the sandwich panel

- Are generally estimated that we are doing this. Do not know how to calculate, but how many people we have to do the number of board

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Use the foam color steel sandwich panel after decoration

- Paste the wallpaper, polystyrene foam board - also known as foam color steel sandwich panels, EPS board is containing volatile liquid blowing agent of the polystyrene beads, heated by heating in the mold after heating It is mainly used in building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, decorative carving and other uses are very extensive. Wallpaper, also known as wallpaper, wall cloth, is a wall for the interior decoration materials, widely used in residential, office, hotels, hotel interior decoration. Material is not limited to paper, but also contains other materials. Because of the colorful, rich patterns, luxurious style, safety and environmental protection, construction convenience, affordable and other kinds of other interior materials can not match the characteristics, so in Europe and the United States, Japan and other developed countries and regions have been a considerable degree of popularity. Wallpaper is divided into many categories, such as film wallpaper, coated wallpaper, embossed wallpaper and so on. Usually with bleached chemical pulp production of base paper, and then by different processes of processing, such as coating, printing, embossing or surface coating, and finally by cutting, packaging after the factory. Has a certain strength, toughness, beautiful appearance and good water resistance.

Send your message to us

Fiber cement composite panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords