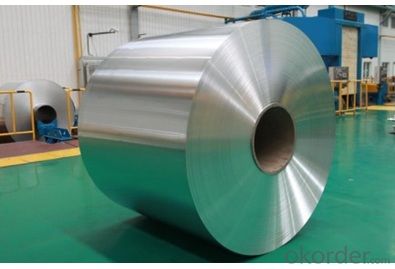

Ruud Air Conditioner Aluminum Coil - See Larger Image High Quality All Applications and Sizes Finished Aluminum Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Aluminium Coil

1 | Alloy | 3003 3004 3005 3105 |

2 | Temper | O H12 H14 H24 H16 H26 H18 H112 F |

3 | Thickness | 0.2mm-10mm |

4 | Width | 500-2200mm |

5 | ID | 508mm 405mm 305mm 150 mm 75mm |

6 | Standard | GB/T,EN,ASTM |

7 | Weight | 1.0 to 5.0 ton/coil or by buyer’s option |

8 | Surface | Mill,Bright, polished, brush, checkered, embossed, etc. |

9 | Payment term | TT,LC,DP,western union,etc |

10 | Price term | EXW,FOB,CFR,CIF,etc |

11 | HS CODE | 76061199 |

12 | Delivery time | According to order’s quantity |

13 | Packing | 1.with wooden pallet packing. 2.standard fumigated wooden package. 3.other packing methods by customer's requirement. |

14 | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. |

15 | Contact | If you have any question, please feel free contact me |

16 | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture,machinery parts, precision machining with the tubes, rods, shaped, sheet metal. |

The Main Features of Aluminium Coil:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

The Images of Aluminium Coil:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: The canoe is aluminum. It has some paint remaining on it from what i am assuming is the original factory paint. The paint is just in patches, so my question is do i sand only where the paint is, or the whole canoe? Will sanding the aluminum damage it? Or should I not sand it at all, and just use paint stripper? After getting the old paint off, what kind of primer should i use? or is it not necessary to prime? What kind of paint should I use? I plan on it being multi tone(a leafy camo, of olive drab, flat black, and a gray tone).

- Go to a paint trade shop tell them what your trying to achieve. They will probably suggest a primer to etch the aluminium. Once its been etched you can paint it any colour you wish. If you don't etch the aluminium, the paint will probably fall off. The etching gives the paint something to adhere to. Cheers!!

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: remember maybe a decade ago or so, copper used to be cheaper than aluminum. now it is the other way around, copper is more expensive. Even copper pennies cost more so I heard they are mixed with another metal to make a penny. What caused the change in value and when did it really start happening?In fact, copper has become valuble enough to steal. Some factories which have copper, have had their metals stolen, but outsiders who break into the factories to specifically take the copper. Then the factories started hiring security to prevent intruders from taking the copper.

- The two metals are a long way apart on the electro-chemical scale. This means that if they come into contact, a small - but significant - voltage will exist between them - completely independent of what currents are actually in the wires. This small voltage causes corrosion of both metals: not good!

- Q: How do aluminum coils contribute to reduced maintenance costs?

- Aluminum coils contribute to reduced maintenance costs due to their corrosion-resistant nature. Unlike other metals, aluminum does not rust or corrode easily, which means that the coils require less maintenance and replacement over time. This leads to cost savings as there is less frequent need for repairs, coatings, or replacements, resulting in reduced maintenance expenses.

- Q: How are aluminum coils used in the production of musical instruments?

- Aluminum coils are commonly used in the production of musical instruments, particularly in wind instruments like saxophones and trumpets. These coils are shaped into a specific design and attached to the instrument to create the desired sound. The aluminum material allows for a lightweight and durable construction, enhancing the instrument's playability and resonance.

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- Aluminum is not biodegradable. Also making aluminum from ore requires a lot of energy. Recycling cans is easy and saves a whole lot of energy reducing green house gases. Recycling aluminum also reduces the mining required to dig up aluminum ore thereby saving the land and stopping pollution from mine run-off.

- Q: What are the storage life and shelf life of aluminum coils?

- The storage life and shelf life of aluminum coils can vary depending on various factors such as the type of alloy, coating, and storage conditions. However, in general, properly stored and maintained aluminum coils can have a storage life of several years and a shelf life of up to 12 months or more. It is important to store them in a dry, clean, and well-ventilated area to minimize the risk of corrosion or other damage. Regular inspection and maintenance are also crucial to ensure their longevity.

- Q: im melting aluminum and what should i use for metal. cans will just oxygenize( i forget the word for it sorry)

- aluminum, in general, will just oxidize if heated in air. it is not just cans that behave that way when they (alcan, alcoa) smelt aluminum industrially they keep it in a reducing environment and do not allow molten aluminum to contact air. so use any aluminum you like but prevent it from contacting air.

- Q: Can kerosene lubricate and cool aluminum coil when continuous punch?

- Yes, because water and oil are not solute, but they will emulsificate.

- Q: Describe the process of rolling aluminum coil in a few sentences.

- <p>The process of rolling aluminum coil involves several key steps. Initially, aluminum ingots are heated to a specific temperature to make them pliable. Then, they are passed through a series of rolling mills where the ingots are pressed and shaped into thin sheets or coils. This process reduces the thickness and increases the length and width of the material. During rolling, the aluminum may be annealed to improve its ductility and strength. After rolling, the aluminum coil is cooled, cleaned, and inspected for quality. The final step includes coiling the rolled aluminum into manageable rolls for storage and transportation. This process is critical for producing aluminum coils used in various industries such as construction, automotive, and packaging.</p>

Send your message to us

Ruud Air Conditioner Aluminum Coil - See Larger Image High Quality All Applications and Sizes Finished Aluminum Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords