Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

Description of Rubber Conveyor Belt

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildew-proof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

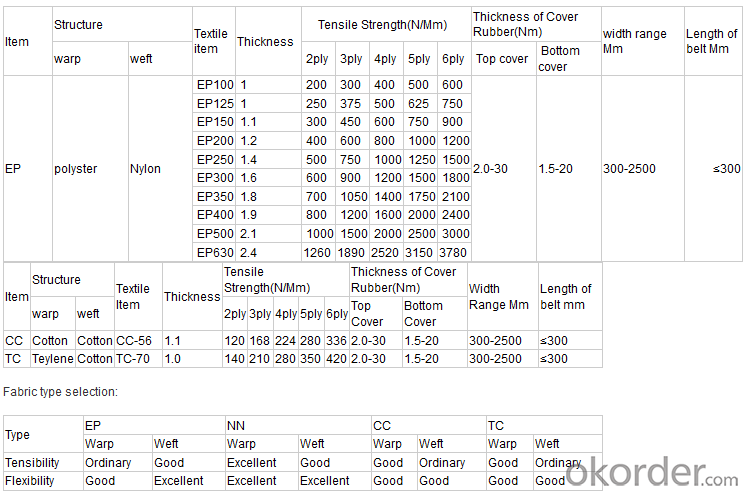

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

USAGE: mining, metallurgical industry and architectural industry, ports etc.

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q:What's the difference between silicone products and rubber products?

- The materials used are different: in other industries, the rubber products used are nitrile rubber, and the silica gel products are made of silica gel.

- Q:What is the definition of mixed rubber?

- Physical property:Its properties vary depending on the monomer, and the properties of a few varieties are similar to those of natural rubber. Some synthetic rubber is superior to natural rubber in good temperature resistance, wear resistance, ageing resistance, corrosion resistance, oil resistance and so on.Under the condition of use, it is highly elastic and has a certain modulus.

- Q:What is the lowest cost material for the synthesis of rubber?

- There are many kinds of synthetic rubber. Many kinds of materials are used in synthesis, which material is lower or can not be measured

- Q:Is there any poison in the processing and testing of rubber products? What about the salary?

- Rubber products processing and testing of this work has low toxicity, pay attention to ventilation, strengthen physical exercise, no problem!! The salary is average, basically between 2500--3500!

- Q:Aging of rubber parts for automobiles

- Automobile rubber parts aging factors are: oxygen, ozone, heat, light, mechanical stress, moisture, oil, other chemicals or radiation, etc.. Attention should be paid to water and oil here:The alternate action of high temperature and oxygen 1. long-term water and in the external environment under the accelerated aging of rubber;2., the oil will penetrate the rubber, so that swelling occurs, rubber performance will be reduced. Therefore, trucks should avoid shock absorption of rubber bushings, oil and diesel in various occasions, including maintenance.

- Q:How does rubber mobile phone cover change yellow?

- Generally discarded, disposed of, replaced by new ones.Can be used to deal with non toothpaste brush view can restore the original color!

- Q:How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

- Q:How to solve the exhaust problem in rubber vulcanization process

- Rubber vulcanization process is a process of high temperature, temperature control, temperature will have material evaporation, products not dense gap, excess glue extrusion emissions, sulfide gas release of many factors such as rubber vulcanization requirements must exhaust can produce qualified products.

- Q:What are the disadvantages of a rubber roof?

- Housing rubber roof area must be greater than the housing area, mainly for water and rubber, heat up, cold weather.

- Q:EPDM rubber foam?

- Three yuan ethylene propylene diene rubber (EPDM) is used as matrix, and azo two, AC and HOBSH are used as foaming agents, in order to systematically and quantitatively study the preparation process of EPDM foam material and the relationship between structure and properties of foamed material. At present, most of EPDM rubber foam material with low reinforcing carbon black filler, fine particles of carbon black can avoid the difficult problem of dispersion and high viscosity, but now the industry of light colored rubber products demand more and more, so this paper using silica as reinforcing filler rubber, studied the preparation process of EPDM foam rubber and the effects of molding conditions on the foaming process. Subsequently, the change of accelerator, filler, foaming agent and the amount of paraffin oil was analyzed. The curing properties, mechanical properties and SEM analysis were carried out, and the influence of various factors on the structure and properties of foamed material was discussed. The influence law of each formula factor on foaming is summarized, and the optimum formula dosage is expected to be found. Finally, we also through the compression behavior of stress-strain curves of EPDM rubber foam materials with different density, the energy absorption efficiency of E and I analysis of the ideal parameters of EPDM foam energy absorption characteristic of absorbing ability of W and.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rubber Conveyor Belt EP/Nylon/CC Canvas Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords