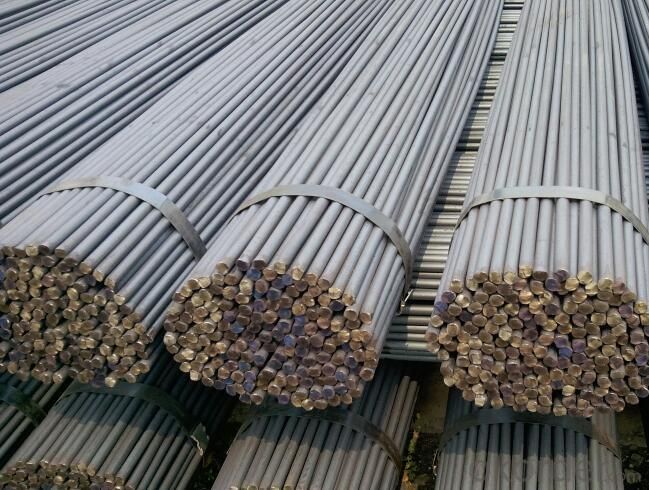

Round steel bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Size:DiameterΦ8-Φ300MM Length:500-8000MM

Surface condition:Lathe polished,descaling,black,acid-producing white,drawn-bright.

Quality assurance:All forged round bar has obtained the certificate of National Level Standard Ultrasonic Flaw Detection.

Inquiry content

1. Product standards

2. Size(Diameter and Length)

3. Surface condition

4. Heat treatment condition

5. Quantity Required

Product introduction:

NS143,20#Alloy,N08020,Alloy 20cb3,Carpenter20Alloy,ALLOY20 is a kind of corrosion resistant alloy which has many superior performance, It has a good ability to resist oxidation ,medium deoxidation corrosion, stress corrosion cracking and local corrosion, its performance satisfies many chemical process, just like inorganic acid solution of strong erosiveness, chlorine and all kinds of medium containing chloride, dry chlorine , formic acid, acetic anhydride, seawater and salt water, etc.

Specialty: resistance to oxidation - reducing composite medium corrosion.

Application: Sulfuric acid environment and sulfuric acid solution which containis LuZu ion and metal ion, such as hydrometallurgy and sulphuric acid industry device.

Detailed Product Description of Skd11 Round Bar Size

We respond to requirements for a wide range of materials including steel for tools, stainless steel, and even aluminum

Please rely on us for any kind of specialist steel.

We mainly offer structural steel, but can offer any other types including tool steel,stainless steel and even aluminium.We can respond to

requests for a wide range of materials.

Please rely on us for quick delivery with short lead times.

We understand well that delivery delays lead to major losses in missed opportunities and lost profits.

We will always endeavor to realize the shortest possible delivery times and to deliver at the time you require.

Please rely on us for high precision processing.

We have a selection of processing machinery, including high precision cutting machines, and will deliver to you after processing into your

required shapes and lengths.

Quality Assurance of Steel Round Rod Bar

1. We will strictly inspect our production that we sold according to the customer’s request.

2. Our steel reaches international quality standards.

3. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

4. Should the packing found damaged, the buyer has the right to claim to the seller.

- Q: What is the hardness of a steel round bar?

- The hardness of a steel round bar can vary depending on the specific type of steel and the manufacturing process used. Steel is typically measured for hardness using the Rockwell hardness scale, which measures the depth of indentation caused by a specific load on a diamond or steel ball. Common hardness values for steel round bars can range from around 20 to 60 Rockwell C (HRC), with higher numbers indicating a harder material. However, it is important to note that the hardness of a steel round bar can also be influenced by factors such as heat treatment, alloying elements, and any surface treatments applied. Therefore, it is essential to consult the specific hardness specifications provided by the manufacturer or supplier to accurately determine the hardness of a steel round bar.

- Q: Can steel round bars be heat treated to improve their mechanical properties?

- Yes, steel round bars can be heat treated to improve their mechanical properties. Heat treatment involves heating the steel to a specific temperature and then cooling it at a controlled rate. This process can alter the microstructure of the steel, resulting in improved hardness, strength, and toughness. Different heat treatment methods, such as quenching and tempering, can be applied depending on the desired mechanical properties.

- Q: How do steel round bars resist corrosion?

- Steel round bars possess corrosion resistance due to a variety of factors. To begin with, steel itself is an alloy primarily composed of iron and carbon. By incorporating other elements like chromium, nickel, and molybdenum, the corrosion resistance of steel is enhanced. These additional elements create a protective oxide layer on the steel's surface, acting as a barrier against corrosive substances in the surroundings. Moreover, steel round bars can undergo further surface treatments or coatings to augment their corrosion resistance. One commonly used technique is galvanization, which involves coating the steel with a layer of zinc. This zinc coating serves as a sacrificial layer, deteriorating before the steel itself is affected. Additionally, steel round bars can be coated with epoxy or other polymer coatings to provide an additional layer of safeguarding. It is also crucial to recognize that the manufacturing process and quality of the steel round bars significantly influence their corrosion resistance. Proper heat treatment, refining techniques, and quality control measures guarantee a homogeneous microstructure and minimal impurities in the steel, thereby reducing the probability of corrosion. In conclusion, the combination of alloying elements, surface treatments, and high-quality manufacturing processes contribute to the corrosion resistance of steel round bars, rendering them a dependable choice for applications in corrosive environments.

- Q: What are the differences between the products made of wrought round steel and hot rolled round steel and tested by mechanical testing after heat treatment?

- In comparison, the general longitudinal performance of hot rolled round bar is better than that of transverse or tangential direction, and the difference between the two values is obvious. The banded structure is more obvious in the longitudinal microstructure, and the deformation of non-metallic plastic inclusions is more obvious

- Q: Can steel round bars be used in the production of HVAC equipment?

- Certainly, HVAC equipment production can indeed make use of steel round bars. In the manufacturing of diverse HVAC components such as air ducts, frames, supports, brackets, and other structural elements, steel round bars find extensive application. Steel is widely preferred in HVAC equipment owing to its exceptional strength, durability, and resistance to corrosion. Its high tensile strength ensures its suitability in handling the mechanical stresses and loads encountered by HVAC systems. Furthermore, steel can endure high temperatures and is non-combustible, rendering it a secure material for HVAC purposes. On the whole, the reliability, longevity, and performance of steel round bars make them extensively employed in HVAC equipment production.

- Q: Can steel round bars be heat treated to enhance their properties?

- Yes, steel round bars can be heat treated to enhance their properties. Heat treatment processes such as quenching, tempering, and annealing can be applied to steel round bars to increase their hardness, strength, and toughness. These treatments can also improve other properties like wear resistance and machinability, making the steel bars more suitable for specific applications.

- Q: What are the different finishes available for steel round bars?

- Steel round bars are available in several finishes, each serving a specific purpose and offering distinct benefits. Some commonly used finishes include: 1. Hot Rolled: By heating the steel above its recrystallization temperature and rapidly cooling it, a rough and scaly surface texture is achieved. This finish provides excellent corrosion resistance and durability. 2. Cold Rolled: The steel is rolled at room temperature, resulting in a smooth and polished finish. Cold rolled steel round bars are known for their precise dimensions, tight tolerances, and improved surface finish. 3. Bright Drawn: This finish involves subjecting the steel round bars to a drawing process, where they are pulled through a die to achieve the desired shape and size. It leaves the surface smooth, bright, and free from imperfections. 4. Polished: Polishing is typically done after cold rolling or drawing the steel round bars. Abrasive materials or chemical treatments are used to remove surface imperfections and create a highly reflective finish. Polished steel round bars are commonly used for decorative purposes. 5. Ground: Grinding is a process where abrasive wheels are used to remove surface imperfections or irregularities from the steel round bars. This results in a smooth and even finish, making the bars suitable for applications requiring tight tolerances and uniformity. 6. Galvanized: Galvanizing involves dipping the steel round bars in a bath of molten zinc, creating a protective layer that prevents corrosion and increases their lifespan. This finish is ideal for outdoor applications or environments with high humidity or moisture. These various finishes offer different properties and appearances, allowing steel round bars to be used in industries such as construction, automotive, manufacturing, and engineering. It is important to consider the specific requirements and conditions of the intended use when selecting the appropriate finish for steel round bars.

- Q: Are steel round bars suitable for outdoor sculptures?

- Indeed, outdoor sculptures can be made with steel round bars. Steel, being a resilient and robust substance, can endure severe weather conditions, including rain, snow, and extreme temperatures. It possesses resistance against corrosion, making it an ideal option for outdoor applications. The malleability of steel round bars allows for effortless shaping and welding, enabling the creation of intricate and elaborate sculptures. Furthermore, steel can be coated with diverse finishes, such as powder coating or paint, to provide additional protection against the elements and enhance its aesthetic appeal. In summary, steel round bars offer the requisite strength, durability, and adaptability necessary for outdoor sculptures.

- Q: 12 of the diameter of the round steel can be M12 out of the thread is not

- It depends on your material straight straight, generally should be right, you check the metric thread specification table, there is large size can be much, I think you are a little round a little better, so that you may get the car, do not appear to have a side material shortage phenomenon

- Q: How do steel round bars compare to stainless steel round bars?

- Steel round bars and stainless steel round bars differ in terms of their composition and properties. Steel round bars are made of carbon steel, which contains varying amounts of carbon and other alloys. They are generally more affordable and widely available, but may be susceptible to corrosion. On the other hand, stainless steel round bars are made of an alloy that contains a higher percentage of chromium. This addition of chromium enhances the corrosion resistance of stainless steel, making it suitable for applications in environments with high moisture or exposure to chemicals. Although stainless steel round bars may be more expensive, they offer superior durability and a polished appearance. Overall, the choice between steel and stainless steel round bars depends on the specific requirements of the application, such as strength, corrosion resistance, and cost-effectiveness.

Send your message to us

Round steel bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords