Roof solar mounting system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

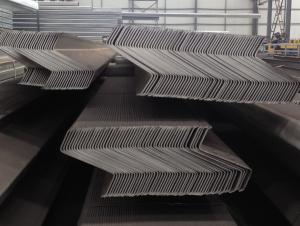

roof solar mounting bracket

1)ISO9001,NZS1170&TUV,MCS certified

2)Fit all kinds of panels

3)Easy installation

roof solar mounting bracket

1.Specification for Roof Solar Mounting Brackets

Item Name | roof solar mounting bracket |

Installation site | Pitch poof top |

Wind resistance | < 60m/s |

Manufacturer process | Stamping and Extrusion |

Features | Fast and secure |

Standard or Non standard | Standard |

Material | Aluminum 6005 T5 & SUS 304 |

Fasten material | Stainless steel |

Anticorrosive | Anodized & Sandblasting |

Quality warranty | 10 years |

Duration | More than 20 years |

2.Feautures of Roof solar Mounting Brackets

Easy Installation: The innovative rail and Ground Screw modules have greatly simplified the installation of PV modules.The System can be installed with a single Hexagon Key and standard tool kit.The Solar Roof system is aided by a very high level of pressembly.The G-Screw module and unique rail extension method allow greatly reduced installation times.

Great Flexbilitity:

With our Roof mounting,frammed photovoltaic modules can be easily mounted on pitched roofs.The Solar Roof system has mounting accessories designed for use on almost every roof cladding available wiht unique rail .Excellent Compatibility.Designed as a unversal racking system,framed modules from all the popular manufacturers can be used.

High Accuracy: Without the need for onsite cutting,the use of our unique rail extending allows the system to be installed with millimetre accuracy.

Excellent Adaptability: The height adjustment of the rails from us allows a level PV array to be established,no matter how uneven the roof.Engineered To High Standard Sunforson SolarRoof is made to the highest standard,safe and strong its designed to Comply with AS/NZS 1170.

Maximum Lifespan: All components are made of quality extruded aluminium and stainless steel.The high corrosion resistance guarantees the maximun possible lifespan and is also completely recyclable.

Guaranteed Durability: Our roof mounting provides a guarantee of 10 years on the durability of all components used.

- Q: Are there any specific requirements for charging station or EV infrastructure design when using a solar mounting system?

- Yes, there are specific requirements for charging station or EV infrastructure design when using a solar mounting system. The design should consider factors such as the orientation and tilt angle of the solar panels to maximize sunlight exposure, the capacity of the solar system to generate sufficient electricity to power the charging station, and the compatibility of the solar mounting system with the specific charging station model. Additionally, considerations should be made for the structural integrity and stability of the mounting system to ensure safety and longevity.

- Q: Can a solar mounting system be installed on a rooftop with a single-ply membrane roof?

- Yes, a solar mounting system can be installed on a rooftop with a single-ply membrane roof.

- Q: Can a solar mounting system be used on thatched roofs?

- Yes, a solar mounting system can be used on thatched roofs with the proper installation techniques and precautions. It is important to ensure that the system is securely anchored to the underlying structure and that the thatched roof is not compromised in the process. Working with experienced professionals who are familiar with both solar installations and thatched roofs is recommended for a safe and effective integration.

- Q: Can a solar mounting system be installed on a rooftop with a butterfly roof?

- Yes, a solar mounting system can be installed on a rooftop with a butterfly roof. However, it may require specific design considerations and modifications to ensure proper installation and functionality of the solar panels.

- Q: Can a solar mounting system be used in areas with solar incentives for parks?

- Yes, a solar mounting system can be used in areas with solar incentives for parks. By installing a solar mounting system in parks, it allows for the generation of renewable energy, which can qualify for various incentives and grants offered by governmental and non-governmental organizations. These incentives can help offset the initial installation costs and provide ongoing financial benefits for the park. Additionally, using solar energy in parks promotes sustainability and environmental conservation, aligning with the goals of many solar incentive programs.

- Q: Can a solar mounting system be installed on a rooftop with a skylight or chimney?

- Yes, a solar mounting system can be installed on a rooftop with a skylight or chimney. However, it is important to consider the location and size of the skylight or chimney when designing the layout of the solar panels. Proper planning and installation techniques can ensure that the solar mounting system does not obstruct or interfere with the skylight or chimney.

- Q: Can a solar mounting system be used in areas with limited access to carbon offset programs?

- Yes, a solar mounting system can definitely be used in areas with limited access to carbon offset programs. Carbon offset programs are voluntary initiatives that allow individuals or businesses to mitigate their carbon emissions by investing in projects that reduce greenhouse gas emissions elsewhere. However, the installation of a solar mounting system itself can directly reduce carbon emissions by generating clean and renewable energy. By utilizing solar power, areas with limited access to carbon offset programs can still contribute to reducing their carbon footprint and promoting sustainability.

- Q: Can a solar mounting system be installed on a rooftop with a vinyl roof?

- Yes, a solar mounting system can be installed on a rooftop with a vinyl roof. The mounting system can be designed to work with various types of roofing materials, including vinyl. However, it is important to ensure that the mounting system is properly installed and that the vinyl roof is structurally sound to support the additional weight and stress of the solar panels. Consulting with a professional solar installer is recommended to ensure a safe and efficient installation.

- Q: What is the weight capacity of a solar mounting system?

- The weight capacity of a solar mounting system can vary depending on various factors such as the type of mounting system, the material used, and the specific design. However, most standard solar mounting systems have a weight capacity of around 2,000 to 10,000 pounds, which allows for the installation of multiple solar panels and ensures the system's stability and durability.

- Q: Can a solar mounting system be used for solar-powered emergency backup systems or disaster relief efforts?

- Yes, a solar mounting system can definitely be used for solar-powered emergency backup systems or disaster relief efforts. These mounting systems provide a secure and stable platform for installing solar panels, allowing them to absorb sunlight and generate electricity even during challenging circumstances. This makes them an ideal solution for providing sustainable and reliable power during emergencies or disaster situations when access to traditional power sources may be disrupted.

Send your message to us

Roof solar mounting system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords